Home UL Type MC Metal Clad Cable UL Type MC Armored Instrumentation, 600 V

UL Type MC Armored Instrumentation, 600 V

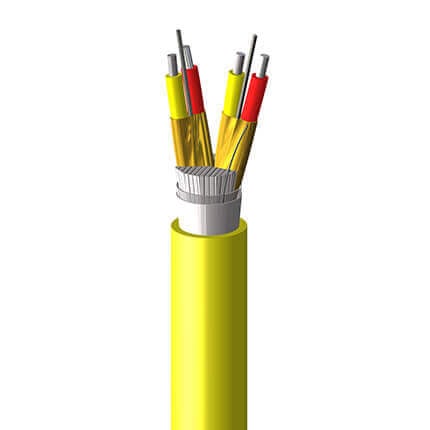

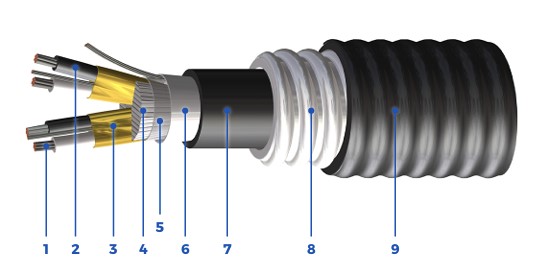

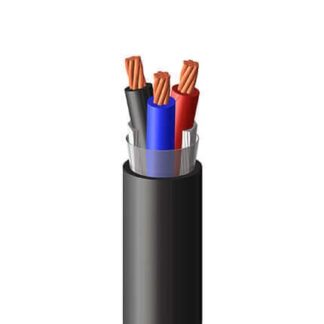

Construction

Voltage

600V

Product Construction

-

- Insulation:

- FR XLPE (XHHW-2 rated) rated: 90°C wet / dry

- VW-1 rated (optional)

- Insulation:

-

- Armor:

- Aluminum Interlocked Armor (AIA) (standard)

- Steel Interlocked Armor (SIA) (optional)

- Armor:

-

- Jacket:

- FR PVC outer black jacket rated: 90°C to -40°C

- Thermoset CPE optional)

- Thermoplastic CPE (optional)

- Thermoplastic LSZH (optional)

- Jacket:

- Available in:

- Custom insulation / jacket colours

- Composite constructions

Colour Coding

- Pairs – Black, & white, with black printing on white (standard)

- Triads – Black, white & red, with black printing on white (standard)

- Method K1 or K2 (optional)

- Method 4 (optional)

Certifications

Certifications/Compliances

- UL 1569, Metal Clad Cables (MC)

- UL 44, Thermoset Insulated Wires and Cables

- UL 1685 / FT4, Vertical Tray Flame Test rated

- IEEE 1202 / 383 (70,000 BTU / hr), Vertical Flame Test rated

- ICEA T-30-520 (70,000 BTU / hr), Vertical Flame Test rated

- XLPE (XHHW-2 rated), 90°C wet / dry

- UV sunlight resistant SUN RES (all colours) (for CT use)

- Direct burial rated

- -40°C cold bend rated

- Rated for use in hazardous locations:

- Class I Zone 2 (Div 2)

- Class II Zone 22 (Div 2)

Properties

- Stranded Bare Copper Conductors (Tinned Available)

- FR XLPE (XHHW-2 Rated) Insulated Conductors

- Individual Shield & Overall Shielded Pairs / Triads

- Polypropylene Fillers

- Polyester Separator Tape

- Overall Aluminum / Mylar Shield with Tinned Copper Drain Wire

- FR PVC Inner Protective Jacket

- Aluminum Interlocked Armor (AIA)

- FR PVC Outer Protective Jacket

PAIRS

| Part Number | Number of Pairs | Conductor Size | OD Over Jacket | Nominal Diameters | Cable Weight | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius(Pull)) | |

| Over Armour | Overall Cable | |||||||

| (AWG/kcmil) | (in/mm) | (in/mm) | (in/mm) | (lbs/1000ft)/ (kg/km) | (lb/kg) | (in/mm) | ||

| 2C621U160100300 | 1 | 16 | 0.337 / 8.6 | 0.577 / 14.7 | 0.689 / 17.5 | 194 / 288 | 41 / 19 | 12.4 / 315 |

| 2C622U160200300 | 2 | 16 | 0.504 / 12.8 | 0.744 / 18.9 | 0.856 / 21.8 | 300 / 446 | 82 / 37 | 15.4 / 392 |

| 2C622U160400300 | 4 | 16 | 0.627 / 15.9 | 0.866 / 22.0 | 0.978 / 24.9 | 401 / 597 | 165 / 75 | 17.6 / 447 |

| 2C622U160600300 | 6 | 16 | 0.736 / 18.7 | 0.976 / 24.8 | 1.088 / 27.6 | 511 / 761 | 247 / 112 | 19.6 / 498 |

| 2C622U160800300 | 8 | 16 | 0.865 / 22.0 | 1.069 / 27.2 | 1.181 / 30.0 | 612 / 911 | 330 / 150 | 21.3 / 540 |

| 2C622U161200300 | 12 | 16 | 0.982 / 24.9 | 1.186 / 30.1 | 1.298 / 33.0 | 783 / 1166 | 494 / 224 | 23.4 / 593 |

| 2C622U161600300 | 16 | 16 | 1.100 / 27.9 | 1.304 / 33.1 | 1.416 / 36.0 | 946 / 1408 | 659 / 299 | 25.5 / 647 |

| 2C622U162400300 | 24 | 16 | 1.378 / 35.0 | 1.582 / 40.2 | 1.714 / 43.6 | 1342 / 1997 | 989 / 449 | 30.9 / 784 |

| 2C622U163600300 | 36 | 16 | 1.597 / 40.6 | 1.801 / 45.8 | 1.933 / 49.1 | 1800 / 2679 | 1483 / 673 | 34.8 / 884 |

| 2C621U180100300 | 1 | 18 | 0.313 / 8.0 | 0.553 / 14.1 | 0.665 / 16.9 | 176 / 261 | 26 / 12 | 12 / 304 |

| 2C622U180200300 | 2 | 18 | 0.465 / 11.8 | 0.705 / 17.9 | 0.817 / 20.7 | 263 / 392 | 52 / 24 | 14.7 / 373 |

| 2C622U180400300 | 4 | 18 | 0.577 / 14.7 | 0.817 / 20.8 | 0.929 / 23.6 | 343 / 511 | 104 / 47 | 16.7 / 425 |

| 2C622U180600300 | 6 | 18 | 0.676 / 17.2 | 0.916 / 23.3 | 1.028 / 26.1 | 428 / 638 | 156 / 71 | 18.5 / 470 |

| 2C622U180800300 | 8 | 18 | 0.792 / 20.1 | 0.996 / 25.3 | 1.108 / 28.1 | 505 / 752 | 208 / 94 | 19.9 / 507 |

| 2C622U181200300 | 12 | 18 | 0.897 / 22.8 | 1.101 / 28.0 | 1.213 / 30.8 | 631 / 939 | 312 / 142 | 21.8 / 555 |

| 2C622U181800300 | 18 | 18 | 1.062 / 27.0 | 1.266 / 32.2 | 1.378 / 35.0 | 821 / 1222 | 468 / 212 | 24.8 / 630 |

| 2C622U182400300 | 24 | 18 | 1.255 / 31.9 | 1.459 / 37.1 | 1.571 / 39.9 | 1024 / 1525 | 624 / 283 | 28.3 / 718 |

| 2C622U183600300 | 36 | 18 | 1.452 / 36.9 | 1.656 / 42.1 | 1.788 / 45.4 | 1387 / 2064 | 936 / 425 | 32.2 / 818 |

TRIADS

| Part Number | Number of Triads | Conductor Size | OD Over Jacket | Nominal Diameters | Cable Weight | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius(Pull)) | |

| Over Armour | Overall Cable | |||||||

| (AWG/kcmil) | (in/mm) | (in/mm) | (in/mm) | (lbs/1000ft)/ (kg/km) | (lb/kg) | (in/mm) | ||

| 2C631U160100300 | 1 | 16 | 0.355 / 9.0 | 0.595 / 15.1 | 0.707 / 18.0 | 212 / 316 | 62 / 28 | 12.7 / 323 |

| 2C632U160200300 | 2 | 16 | 0.595 / 15.1 | 0.835 / 21.2 | 0.947 / 24.1 | 369 / 549 | 124 / 56 | 17 / 433 |

| 2C632U160400300 | 4 | 16 | 0.715 / 18.2 | 0.955 / 24.3 | 1.067 / 27.1 | 483 / 719 | 247 / 112 | 19.2 / 488 |

| 2C632U160600300 | 6 | 16 | 0.843 / 21.4 | 1.047 / 26.6 | 1.159 / 29.4 | 620 / 923 | 371 / 168 | 20.9 / 530 |

| 2C632U160800300 | 8 | 16 | 0.993 / 25.2 | 1.197 / 30.4 | 1.309 / 33.3 | 761 / 1132 | 494 / 224 | 23.6 / 599 |

| 2C632U161200300 | 12 | 16 | 1.128 / 28.7 | 1.332 / 33.8 | 1.444 / 36.7 | 989 / 1471 | 742 / 336 | 26 / 660 |

| 2C632U161600300 | 16 | 16 | 1.266 / 32.2 | 1.470 / 37.4 | 1.582 / 40.2 | 1207 / 1796 | 989 / 449 | 28.5 / 723 |

| 2C632U162400300 | 24 | 16 | 1.591 / 40.4 | 1.795 / 45.6 | 1.927 / 49.0 | 1727 / 2570 | 1483 / 673 | 34.7 / 881 |

| 2C631U180100300 | 1 | 18 | 0.329 / 8.4 | 0.569 / 14.5 | 0.681 / 17.3 | 189 / 282 | 39 / 18 | 12.3 / 311 |

| 2C632U180200300 | 2 | 18 | 0.548 / 13.9 | 0.788 / 20.1 | 0.900 / 22.9 | 322 / 479 | 78 / 35 | 16.2 / 412 |

| 2C632U180400300 | 4 | 18 | 0.656 / 16.7 | 0.896 / 22.8 | 1.008 / 25.6 | 409 / 609 | 156 / 71 | 18.1 / 461 |

| 2C632U180600300 | 6 | 18 | 0.771 / 19.6 | 0.991 / 25.2 | 1.103 / 28.0 | 516 / 768 | 234 / 106 | 19.9 / 504 |

| 2C632U180800300 | 8 | 18 | 0.907 / 23.0 | 1.111 / 28.2 | 1.222 / 31.1 | 622 / 925 | 312 / 142 | 22 / 559 |

| 2C632U181200300 | 12 | 18 | 1.029 / 26.1 | 1.233 / 31.3 | 1.345 / 34.2 | 796 / 1185 | 468 / 212 | 24.2 / 615 |

| 2C632U181800300 | 18 | 18 | 1.221 / 31.0 | 1.425 / 36.2 | 1.537 / 39.0 | 1046 / 1557 | 702 / 318 | 27.7 / 703 |

| 2C632U182400300 | 24 | 18 | 1.446 / 36.7 | 1.649 / 41.9 | 1.781 / 45.3 | 1352 / 2011 | 936 / 425 | 32.1 / 814 |

Markets / Applications

|

|

Voltage

600V

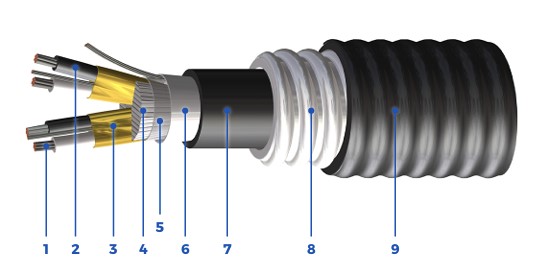

Product Construction

-

- Insulation:

- FR XLPE (XHHW-2 rated) rated: 90°C wet / dry

- VW-1 rated (optional)

- Insulation:

-

- Armor:

- Aluminum Interlocked Armor (AIA) (standard)

- Steel Interlocked Armor (SIA) (optional)

- Armor:

-

- Jacket:

- FR PVC outer black jacket rated: 90°C to -40°C

- Thermoset CPE optional)

- Thermoplastic CPE (optional)

- Thermoplastic LSZH (optional)

- Jacket:

- Available in:

- Custom insulation / jacket colours

- Composite constructions

Colour Coding

- Pairs – Black, & white, with black printing on white (standard)

- Triads – Black, white & red, with black printing on white (standard)

- Method K1 or K2 (optional)

- Method 4 (optional)

Certifications/Compliances

- UL 1569, Metal Clad Cables (MC)

- UL 44, Thermoset Insulated Wires and Cables

- UL 1685 / FT4, Vertical Tray Flame Test rated

- IEEE 1202 / 383 (70,000 BTU / hr), Vertical Flame Test rated

- ICEA T-30-520 (70,000 BTU / hr), Vertical Flame Test rated

- XLPE (XHHW-2 rated), 90°C wet / dry

- UV sunlight resistant SUN RES (all colours) (for CT use)

- Direct burial rated

- -40°C cold bend rated

- Rated for use in hazardous locations:

- Class I Zone 2 (Div 2)

- Class II Zone 22 (Div 2)

- Stranded Bare Copper Conductors (Tinned Available)

- FR XLPE (XHHW-2 Rated) Insulated Conductors

- Individual Shield & Overall Shielded Pairs / Triads

- Polypropylene Fillers

- Polyester Separator Tape

- Overall Aluminum / Mylar Shield with Tinned Copper Drain Wire

- FR PVC Inner Protective Jacket

- Aluminum Interlocked Armor (AIA)

- FR PVC Outer Protective Jacket

PAIRS

| Part Number | Number of Pairs | Conductor Size | OD Over Jacket | Nominal Diameters | Cable Weight | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius(Pull)) | |

| Over Armour | Overall Cable | |||||||

| (AWG/kcmil) | (in/mm) | (in/mm) | (in/mm) | (lbs/1000ft)/ (kg/km) | (lb/kg) | (in/mm) | ||

| 2C621U160100300 | 1 | 16 | 0.337 / 8.6 | 0.577 / 14.7 | 0.689 / 17.5 | 194 / 288 | 41 / 19 | 12.4 / 315 |

| 2C622U160200300 | 2 | 16 | 0.504 / 12.8 | 0.744 / 18.9 | 0.856 / 21.8 | 300 / 446 | 82 / 37 | 15.4 / 392 |

| 2C622U160400300 | 4 | 16 | 0.627 / 15.9 | 0.866 / 22.0 | 0.978 / 24.9 | 401 / 597 | 165 / 75 | 17.6 / 447 |

| 2C622U160600300 | 6 | 16 | 0.736 / 18.7 | 0.976 / 24.8 | 1.088 / 27.6 | 511 / 761 | 247 / 112 | 19.6 / 498 |

| 2C622U160800300 | 8 | 16 | 0.865 / 22.0 | 1.069 / 27.2 | 1.181 / 30.0 | 612 / 911 | 330 / 150 | 21.3 / 540 |

| 2C622U161200300 | 12 | 16 | 0.982 / 24.9 | 1.186 / 30.1 | 1.298 / 33.0 | 783 / 1166 | 494 / 224 | 23.4 / 593 |

| 2C622U161600300 | 16 | 16 | 1.100 / 27.9 | 1.304 / 33.1 | 1.416 / 36.0 | 946 / 1408 | 659 / 299 | 25.5 / 647 |

| 2C622U162400300 | 24 | 16 | 1.378 / 35.0 | 1.582 / 40.2 | 1.714 / 43.6 | 1342 / 1997 | 989 / 449 | 30.9 / 784 |

| 2C622U163600300 | 36 | 16 | 1.597 / 40.6 | 1.801 / 45.8 | 1.933 / 49.1 | 1800 / 2679 | 1483 / 673 | 34.8 / 884 |

| 2C621U180100300 | 1 | 18 | 0.313 / 8.0 | 0.553 / 14.1 | 0.665 / 16.9 | 176 / 261 | 26 / 12 | 12 / 304 |

| 2C622U180200300 | 2 | 18 | 0.465 / 11.8 | 0.705 / 17.9 | 0.817 / 20.7 | 263 / 392 | 52 / 24 | 14.7 / 373 |

| 2C622U180400300 | 4 | 18 | 0.577 / 14.7 | 0.817 / 20.8 | 0.929 / 23.6 | 343 / 511 | 104 / 47 | 16.7 / 425 |

| 2C622U180600300 | 6 | 18 | 0.676 / 17.2 | 0.916 / 23.3 | 1.028 / 26.1 | 428 / 638 | 156 / 71 | 18.5 / 470 |

| 2C622U180800300 | 8 | 18 | 0.792 / 20.1 | 0.996 / 25.3 | 1.108 / 28.1 | 505 / 752 | 208 / 94 | 19.9 / 507 |

| 2C622U181200300 | 12 | 18 | 0.897 / 22.8 | 1.101 / 28.0 | 1.213 / 30.8 | 631 / 939 | 312 / 142 | 21.8 / 555 |

| 2C622U181800300 | 18 | 18 | 1.062 / 27.0 | 1.266 / 32.2 | 1.378 / 35.0 | 821 / 1222 | 468 / 212 | 24.8 / 630 |

| 2C622U182400300 | 24 | 18 | 1.255 / 31.9 | 1.459 / 37.1 | 1.571 / 39.9 | 1024 / 1525 | 624 / 283 | 28.3 / 718 |

| 2C622U183600300 | 36 | 18 | 1.452 / 36.9 | 1.656 / 42.1 | 1.788 / 45.4 | 1387 / 2064 | 936 / 425 | 32.2 / 818 |

TRIADS

| Part Number | Number of Triads | Conductor Size | OD Over Jacket | Nominal Diameters | Cable Weight | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius(Pull)) | |

| Over Armour | Overall Cable | |||||||

| (AWG/kcmil) | (in/mm) | (in/mm) | (in/mm) | (lbs/1000ft)/ (kg/km) | (lb/kg) | (in/mm) | ||

| 2C631U160100300 | 1 | 16 | 0.355 / 9.0 | 0.595 / 15.1 | 0.707 / 18.0 | 212 / 316 | 62 / 28 | 12.7 / 323 |

| 2C632U160200300 | 2 | 16 | 0.595 / 15.1 | 0.835 / 21.2 | 0.947 / 24.1 | 369 / 549 | 124 / 56 | 17 / 433 |

| 2C632U160400300 | 4 | 16 | 0.715 / 18.2 | 0.955 / 24.3 | 1.067 / 27.1 | 483 / 719 | 247 / 112 | 19.2 / 488 |

| 2C632U160600300 | 6 | 16 | 0.843 / 21.4 | 1.047 / 26.6 | 1.159 / 29.4 | 620 / 923 | 371 / 168 | 20.9 / 530 |

| 2C632U160800300 | 8 | 16 | 0.993 / 25.2 | 1.197 / 30.4 | 1.309 / 33.3 | 761 / 1132 | 494 / 224 | 23.6 / 599 |

| 2C632U161200300 | 12 | 16 | 1.128 / 28.7 | 1.332 / 33.8 | 1.444 / 36.7 | 989 / 1471 | 742 / 336 | 26 / 660 |

| 2C632U161600300 | 16 | 16 | 1.266 / 32.2 | 1.470 / 37.4 | 1.582 / 40.2 | 1207 / 1796 | 989 / 449 | 28.5 / 723 |

| 2C632U162400300 | 24 | 16 | 1.591 / 40.4 | 1.795 / 45.6 | 1.927 / 49.0 | 1727 / 2570 | 1483 / 673 | 34.7 / 881 |

| 2C631U180100300 | 1 | 18 | 0.329 / 8.4 | 0.569 / 14.5 | 0.681 / 17.3 | 189 / 282 | 39 / 18 | 12.3 / 311 |

| 2C632U180200300 | 2 | 18 | 0.548 / 13.9 | 0.788 / 20.1 | 0.900 / 22.9 | 322 / 479 | 78 / 35 | 16.2 / 412 |

| 2C632U180400300 | 4 | 18 | 0.656 / 16.7 | 0.896 / 22.8 | 1.008 / 25.6 | 409 / 609 | 156 / 71 | 18.1 / 461 |

| 2C632U180600300 | 6 | 18 | 0.771 / 19.6 | 0.991 / 25.2 | 1.103 / 28.0 | 516 / 768 | 234 / 106 | 19.9 / 504 |

| 2C632U180800300 | 8 | 18 | 0.907 / 23.0 | 1.111 / 28.2 | 1.222 / 31.1 | 622 / 925 | 312 / 142 | 22 / 559 |

| 2C632U181200300 | 12 | 18 | 1.029 / 26.1 | 1.233 / 31.3 | 1.345 / 34.2 | 796 / 1185 | 468 / 212 | 24.2 / 615 |

| 2C632U181800300 | 18 | 18 | 1.221 / 31.0 | 1.425 / 36.2 | 1.537 / 39.0 | 1046 / 1557 | 702 / 318 | 27.7 / 703 |

| 2C632U182400300 | 24 | 18 | 1.446 / 36.7 | 1.649 / 41.9 | 1.781 / 45.3 | 1352 / 2011 | 936 / 425 | 32.1 / 814 |

|

|

Related products

-

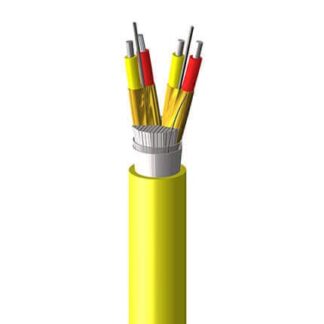

CSA TYPE CIC TC Tray Thermocouple Extension, 300 V

View Product: CSA TYPE CIC TC Tray Thermocouple Extension, 300 VCSA TYPE CIC TC Tray Thermocouple Extension, 300 V

Thermocouple Extension cables offer advantages in cost and mechanical properties when used for connections between thermocouples and instruments.

CSA TYPE CIC TC Tray Thermocouple Extension, 300 V

Thermocouple Extension cables offer advantages in cost and mechanical properties when used for connections between thermocouples and instruments.

MORE DETAILS -

CSA LSZH TYPE ACIC Armoured Control, Multi-Conductor, 1000 V

View Product: CSA LSZH TYPE ACIC Armoured Control, Multi-Conductor, 1000 VCSA LSZH TYPE ACIC Armoured Control, Multi-Conductor, 1000 V

LSZH AIA Control cables are suitable for use in ventilated, non-ventilated and ladder type cable trays, direct burial, raceways and for exposed or concealed wiring in wet, damp or dry locations in -40°C (-40°F) environments. Applicable for use in Utilities, Industrial and Commercial applications.

SKU: 1535 Categories: CSA Type ACIC Armoured Control & Instrumentation, CSA Type Teck 90 Armoured Cable, Building WireCSA LSZH TYPE ACIC Armoured Control, Multi-Conductor, 1000 V

LSZH AIA Control cables are suitable for use in ventilated, non-ventilated and ladder type cable trays, direct burial, raceways and for exposed or concealed wiring in wet, damp or dry locations in -40°C (-40°F) environments. Applicable for use in Utilities, Industrial and Commercial applications.

MORE DETAILS -

UL Type TC Tray Control, Multi-Conductor, 2000 V

View Product: UL Type TC Tray Control, Multi-Conductor, 2000 VUL Type TC Tray Control, Multi-Conductor, 2000 V

Tray Control cables are suitable for use in ventilated, non-ventilated and ladder type cable trays, direct burial, raceways and for exposed or concealed wiring in wet, damp or dry locations in -40°C (-40°F) environments. Applicable for use in Utilities, Industrial and Commercial applications.

SKU: 1759 Categories: UL Type TC Tray Cable, Building WireUL Type TC Tray Control, Multi-Conductor, 2000 V

Tray Control cables are suitable for use in ventilated, non-ventilated and ladder type cable trays, direct burial, raceways and for exposed or concealed wiring in wet, damp or dry locations in -40°C (-40°F) environments. Applicable for use in Utilities, Industrial and Commercial applications.

MORE DETAILS