Innovation

Designing and executing technology and customer solutions from concept to commercial reality.

At Shawflex, we offer customers much more than a catalog of products. To produce a dependable and superior product, we provide the technical leadership and service responsiveness needed to meet all your project deadlines as well as your performance requirements, for end-to-end cable manufacturing through terminated assembly services.

Dedicated to Solutions

At the heart of our commitment to our customers is our Solutions Development Team. They are dedicated to constantly push the boundaries of materials technologies, complex manufacturing techniques and custom testing programs. The Solutions Development Team designs products & services that are safer, more reliable, and more innovative to ensure they meet the highest standards for our customers’ applications.

We develop, test and certify our solutions to match the needs and requirements of our customers. We have built this capability by working side by side with our customers on new materials, challenging designs, and rigorous testing programs before applying our product in the field. Our test and measurement facilities help ensure every wire, cable, cable assembly, and connector meet or exceed your expectations.

Leverage our wire and cable materials and design expertise

Shawflex wire and cable products utilize a wide variety of engineered materials to meet performance and regulatory requirements such as XLPE, XLPO, PVC, EPR, EPDM, TPU, FEP and others. Our materials specialists are experts in the selection, testing, analysis, and qualification of materials to meet customer needs and develop engineered-to-order solutions. We will select and combine materials from our large portfolio to build high performance products or work with customers to tailor material solutions to their needs. Shawflex specializes in short run, unique configuration cable manufacturing. While other cable manufacturers will make 1000’s of metres of the same cable we will build one off tailored product to meet unique customer needs.

Performance Cable Assemblies & Harnesses

We are a global leader in cable assembly and harness solutions that meet the highest standards for various industries, from Aerospace to Nuclear. Shawflex cables are vertically integrated with Kanata connectors and terminations to offer a complete solution that helps reduce costs, streamline installation, and ensure efficient and reliable connectivity.

Unique Capabilities for meeting Process Engineering Challenges

Shawflex has a dedicated team of experts managing process engineering, tooling design and development. We provide quick turnaround designs to our customers and develop customized tooling and engineered manufacturing solutions for unique processing challenges. We have in-house 3D printing capabilities for prototype tooling and solutions development. Our experienced team of professionals adapt to the challenges of continuous improvement, efficiency and quality maintenance in a structured standards driven environment.

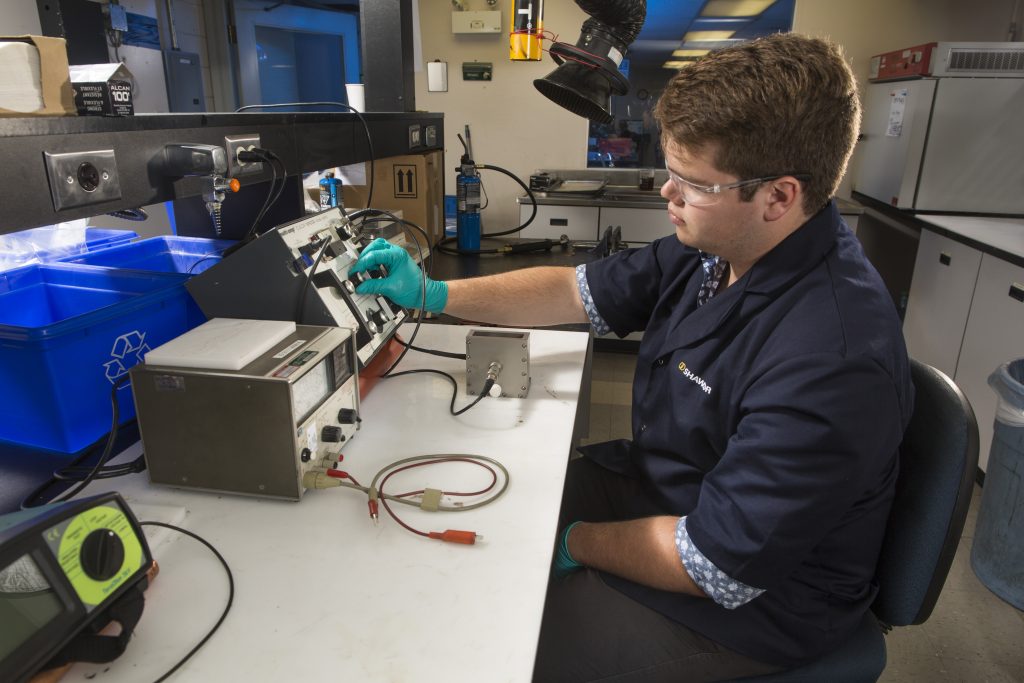

Custom test program and equipment development

Shawflex partners with customers to design, develop and build customized test programs and equipment for unique application performance evaluation and qualification. Shawflex often makes shorter lengths of distinctive cable designs. As such these unique cables often require unique performance testing which may not be readily available. Shawflex will offer a custom test program as part of our solution to ensure our products will meet your performance requirements before installation. This includes our in-house services to design and develop unique test equipment for the most complex application testing conditions. We also have specialized capabilities to test performance of nuclear grade cables with a full range of accredited Nuclear Cable Engineering Services.

Meeting regulatory standards and certification with our experts

Shawflex is qualified to manufacture products in accordance with multiple industry regulatory standards such as CSA, UL, ICEA, AREMA and IEC as well as unique customer standards within the Utility, Transit and Infrastructure markets, including meeting the high standards of CANDU Nuclear operators globally. Our Product Engineers are experts in navigating the product certification landscape and can support customers with unique solutions backed up by industry recognized credentials which guarantee reliability and quality.

To meet an expert, contact us today!

To know more about our product and service capabilities, contact our team of experts today.