CSA TYPE CIC TC Tray Thermocouple Extension, 300 V

Thermocouple Extension cables offer advantages in cost and mechanical properties when used for connections between thermocouples and instruments.

Construction

Voltage

300 V

Optional: 600V

Product Construction

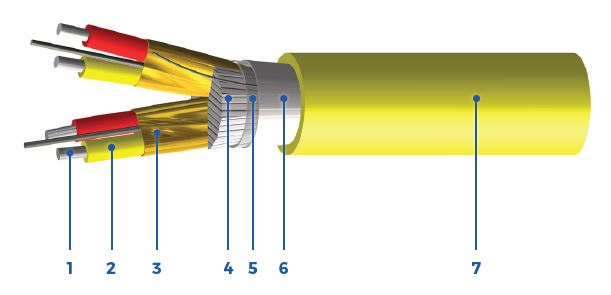

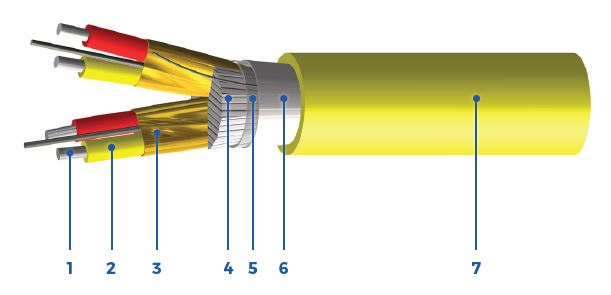

Insulation:

XLPE (RW90 rated) rated: 90°C wet/105°C dry

Shielding (foil-free edge):

ISOS (standard)

OS (optional)

Jacket:

FR PVC yellow dependent on requested thermocouple alloy rated: 90°C to -40°C

Available in:

Composite constructions

Custom insulation/jacket colours

Extension cables for type E, J, K, N, R, S and T thermocouple alloys

Certifications

Certifications/Compliances

- CSA C22.2 No. 230, Tray cables

- CSA C22.2 No. 239, Control and instrumentation cables

- CSA C22.2 No. 38, Thermoset-insulated wires and cables

- CSA C22.2 No. 2556/UL 2556 FT4,Vertical Tray Flame Test rated

- IEEE 383/1202 (70,000 BTU/hr), Vertical Flame Test rated

- XLPE (RW90 rated), 90°C wet/ 105°C dry

- UV sunlight resistant “SUN RES” (all colours)

- Direct burial rated

- -40°C cold bend/impact rated

- Rated for use in hazardous locations:

- Zone 0 (Class 1, Division 1) (Intrinsically Safe circuits only)

- Zone 2 (Div 2)

- TC-BCD gas groups rated

Colour Coding

- Type EX: (+) Purple (-) Red Purple jacket

- Type JX: (+) White (-) Red Black jacket

- Type KX: (+) Yellow (-) Red Yellow jacket

- Type NX: (+) Orange (-) Red Orange jacket

- Type RX/SX: (+) Black (-) Red Green jacket

- Type TX: (+) Blue (-) Red Blue jacket

Properties

- Thermocouple Alloys

- Insulated Thermocouple Alloy Wires

- Individual Aluminum/Mylar Shielded Pairs with Tin-coated Copper Drain Wire

- Polypropylene Fillers

- Polyester Separator Tape

- Overall Aluminum/Mylar Shield with Tin-coated Copper Drain Wire

- FR PVC Outer Protective Jacket

| Part Number | Number of Pairs | Conductor Size | Nominal Diameter Overall Cable | Cable Weight | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) |

| AWG | in. | mm | lb/1000ft | kg/km |

lb | kg | in. | mm | ||

| 7B021M1601XY0T8 | 1 | 16 | 0.337 | 8.6 | 52 | 78 | 41.0 | 19 | 6.1 | 154 |

| 7B022M1602XY0T8 | 2 | 16 | 0.498 | 12.7 | 117 | 174 | 82.0 | 37 | 9.0 | 228 |

| 7B022M1604XY0T8 | 4 | 16 | 0.612 | 15.6 | 183 | 273 | 165.0 | 75 | 11.0 | 280 |

| 7B022M1606XY0T8 | 6 | 16 | 0.731 | 18.6 | 262 | 390 | 247.0 | 112 | 13.2 | 334 |

| 7B022M1608XY0T8 | 8 | 16 | 0.793 | 20.2 | 322 | 480 | 330.0 | 150 | 14.3 | 363 |

| 7B022M1612XY0T8 | 12 | 16 | 1.007 | 25.6 | 493 | 733 | 494.0 | 224 | 18.1 | 460 |

| 7B022M1624XY0T8 | 24 | 16 | 1.387 | 35.2 | 890 | 1324 | 989.0 | 449 | 25.0 | 634 |

| 7B021M1801XY0T8 | 1 | 18 | 0.315 | 8 | 43 | 64 | 26.0 | 12 | 5.7 | 144 |

| 7B022M1802XY0T8 | 2 | 18 | 0.462 | 11.7 | 96 | 143 | 52.0 | 24 | 8.3 | 211 |

| 7B022M1804XY0T8 | 4 | 18 | 0.568 | 14.4 | 147 | 218 | 104.0 | 47 | 10.2 | 260 |

| 7B022M1806XY0T8 | 6 | 18 | 0.676 | 17.2 | 207 | 308 | 156.0 | 71 | 12.2 | 309 |

| 7B022M1808XY0T8 | 8 | 18 | 0.732 | 18.6 | 253 | 377 | 208.0 | 94 | 13.2 | 335 |

| 7B022M1812XY0T8 | 12 | 18 | 0.929 | 23.6 | 386 | 575 | 312.0 | 142 | 16.7 | 425 |

| 7B022M1824XY0T8 | 24 | 18 | 1.274 | 32.36 | 685 | 1019 | 624.0 | 283 | 22.9 | 583 |

| 7B021M2001XY0T8 | 1 | 20 | 0.299 | 7.6 | 38 | 56 | 16.0 | 7 | 5.4 | 137 |

| 7B022M2002XY0T8 | 2 | 20 | 0.435 | 11.1 | 83 | 124 | 32.0 | 15 | 7.8 | 199 |

| 7B022M2004XY0T8 | 4 | 20 | 0.506 | 12.9 | 112 | 167 | 64.0 | 29 | 9.1 | 231 |

| 7B022M2006XY0T8 | 6 | 20 | 0.636 | 16.2 | 176 | 261 | 96.0 | 44 | 11.4 | 291 |

| 7B022M2008XY0T8 | 8 | 20 | 0.688 | 17.5 | 212 | 316 | 128.0 | 58 | 12.4 | 314 |

| 7B022M2012XY0T8 | 12 | 20 | 0.833 | 21.2 | 293 | 436 | 192.0 | 87 | 15.0 | 381 |

| 7B022M2024XY0T8 | 24 | 20 | 1.192 | 30.3 | 568 | 845 | 384.0 | 174 | 21.5 | 545 |

Markets / Applications

- Generation – Renewables – Wind

- Transit

- Water/Waste Water Treatment

- Shipboard

- Generation

- Communication Power & Control

- Generation – Nuclear

- Power Distribution

- Industrial Construction/Automation

- Civil Construction Projects

- Power Distribution – LV

- Generation – Renewables

- Petrochem/Pulp & Paper

- Utility

- Commercial Construction Projects

- Generation – Renewables – Geo Thermal

- Generation – Renewables – Solar

- Mining

Voltage

300 V

Optional: 600V

Product Construction

Insulation:

XLPE (RW90 rated) rated: 90°C wet/105°C dry

Shielding (foil-free edge):

ISOS (standard)

OS (optional)

Jacket:

FR PVC yellow dependent on requested thermocouple alloy rated: 90°C to -40°C

Available in:

Composite constructions

Custom insulation/jacket colours

Extension cables for type E, J, K, N, R, S and T thermocouple alloys

Certifications/Compliances

- CSA C22.2 No. 230, Tray cables

- CSA C22.2 No. 239, Control and instrumentation cables

- CSA C22.2 No. 38, Thermoset-insulated wires and cables

- CSA C22.2 No. 2556/UL 2556 FT4,Vertical Tray Flame Test rated

- IEEE 383/1202 (70,000 BTU/hr), Vertical Flame Test rated

- XLPE (RW90 rated), 90°C wet/ 105°C dry

- UV sunlight resistant “SUN RES” (all colours)

- Direct burial rated

- -40°C cold bend/impact rated

- Rated for use in hazardous locations:

- Zone 0 (Class 1, Division 1) (Intrinsically Safe circuits only)

- Zone 2 (Div 2)

- TC-BCD gas groups rated

Colour Coding

- Type EX: (+) Purple (-) Red Purple jacket

- Type JX: (+) White (-) Red Black jacket

- Type KX: (+) Yellow (-) Red Yellow jacket

- Type NX: (+) Orange (-) Red Orange jacket

- Type RX/SX: (+) Black (-) Red Green jacket

- Type TX: (+) Blue (-) Red Blue jacket

- Thermocouple Alloys

- Insulated Thermocouple Alloy Wires

- Individual Aluminum/Mylar Shielded Pairs with Tin-coated Copper Drain Wire

- Polypropylene Fillers

- Polyester Separator Tape

- Overall Aluminum/Mylar Shield with Tin-coated Copper Drain Wire

- FR PVC Outer Protective Jacket

| Part Number | Number of Pairs | Conductor Size | Nominal Diameter Overall Cable | Cable Weight | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) |

| AWG | in. | mm | lb/1000ft | kg/km |

lb | kg | in. | mm | ||

| 7B021M1601XY0T8 | 1 | 16 | 0.337 | 8.6 | 52 | 78 | 41.0 | 19 | 6.1 | 154 |

| 7B022M1602XY0T8 | 2 | 16 | 0.498 | 12.7 | 117 | 174 | 82.0 | 37 | 9.0 | 228 |

| 7B022M1604XY0T8 | 4 | 16 | 0.612 | 15.6 | 183 | 273 | 165.0 | 75 | 11.0 | 280 |

| 7B022M1606XY0T8 | 6 | 16 | 0.731 | 18.6 | 262 | 390 | 247.0 | 112 | 13.2 | 334 |

| 7B022M1608XY0T8 | 8 | 16 | 0.793 | 20.2 | 322 | 480 | 330.0 | 150 | 14.3 | 363 |

| 7B022M1612XY0T8 | 12 | 16 | 1.007 | 25.6 | 493 | 733 | 494.0 | 224 | 18.1 | 460 |

| 7B022M1624XY0T8 | 24 | 16 | 1.387 | 35.2 | 890 | 1324 | 989.0 | 449 | 25.0 | 634 |

| 7B021M1801XY0T8 | 1 | 18 | 0.315 | 8 | 43 | 64 | 26.0 | 12 | 5.7 | 144 |

| 7B022M1802XY0T8 | 2 | 18 | 0.462 | 11.7 | 96 | 143 | 52.0 | 24 | 8.3 | 211 |

| 7B022M1804XY0T8 | 4 | 18 | 0.568 | 14.4 | 147 | 218 | 104.0 | 47 | 10.2 | 260 |

| 7B022M1806XY0T8 | 6 | 18 | 0.676 | 17.2 | 207 | 308 | 156.0 | 71 | 12.2 | 309 |

| 7B022M1808XY0T8 | 8 | 18 | 0.732 | 18.6 | 253 | 377 | 208.0 | 94 | 13.2 | 335 |

| 7B022M1812XY0T8 | 12 | 18 | 0.929 | 23.6 | 386 | 575 | 312.0 | 142 | 16.7 | 425 |

| 7B022M1824XY0T8 | 24 | 18 | 1.274 | 32.36 | 685 | 1019 | 624.0 | 283 | 22.9 | 583 |

| 7B021M2001XY0T8 | 1 | 20 | 0.299 | 7.6 | 38 | 56 | 16.0 | 7 | 5.4 | 137 |

| 7B022M2002XY0T8 | 2 | 20 | 0.435 | 11.1 | 83 | 124 | 32.0 | 15 | 7.8 | 199 |

| 7B022M2004XY0T8 | 4 | 20 | 0.506 | 12.9 | 112 | 167 | 64.0 | 29 | 9.1 | 231 |

| 7B022M2006XY0T8 | 6 | 20 | 0.636 | 16.2 | 176 | 261 | 96.0 | 44 | 11.4 | 291 |

| 7B022M2008XY0T8 | 8 | 20 | 0.688 | 17.5 | 212 | 316 | 128.0 | 58 | 12.4 | 314 |

| 7B022M2012XY0T8 | 12 | 20 | 0.833 | 21.2 | 293 | 436 | 192.0 | 87 | 15.0 | 381 |

| 7B022M2024XY0T8 | 24 | 20 | 1.192 | 30.3 | 568 | 845 | 384.0 | 174 | 21.5 | 545 |

- Generation – Renewables – Wind

- Transit

- Water/Waste Water Treatment

- Shipboard

- Generation

- Communication Power & Control

- Generation – Nuclear

- Power Distribution

- Industrial Construction/Automation

- Civil Construction Projects

- Power Distribution – LV

- Generation – Renewables

- Petrochem/Pulp & Paper

- Utility

- Commercial Construction Projects

- Generation – Renewables – Geo Thermal

- Generation – Renewables – Solar

- Mining