CSA TYPE TECK 90 Armoured Power, Single-Conductor, Unshielded, 5000 V

Construction

VOLTAGE

5000 V

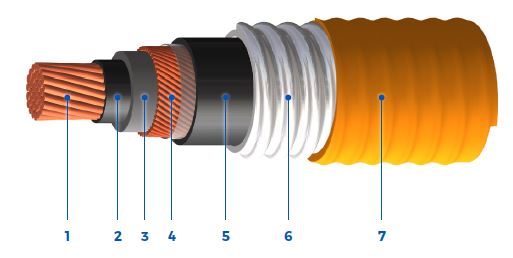

PRODUCT CONSTRUCTION

Conductor Shield:

Extruded, concentric, thermoset semiconducting material

Insulation:

XLPE (RW90 rated) rated: 90°C wet/105°C dry

Bonding Conductor:

Concentric serving of solid bare copper wires applied over the insulation

Armour:

Aluminum Interlocked Armour (AIA) (standard)

Jacket:

FR LAG PVC (AG14 rated) inner black jacket rated: 90°C to -40°C

FR LAG PVC (AG14 rated) outer orange jacket rated: 90°C to -40°C

Available in:

Ribbed inner-jacketed core for vertical/mineshaft applications

Custom insulation / jacket colours

Aluminum conductors

Certifications

Certifications/Compliances

- CSA C22.2 No. 131, Type TECK 90 cable

- CSA C22.2 No. 174, Cables and cable glands for use in hazardous locations

- CSA C22.2 No. 38, Thermoset-insulated wires and cables

- CSA C22.2 No. 2556/UL 2556 FT4, Vertical Tray Flame Test rated

- IEEE 383/1202 (70,000 BTU/hr), Vertical Flame Test rated

- XLPE (RW90 rated), 90°C wet/dry

- UV sunlight resistant “SUN RES” (all colours)

- Direct burial rated

- -40°C cold bend/impact rated

- HL rated for use in hazardous locations:

- Zone 0 (Class 1, Division 1) (Intrinsically Safe circuits only)

- Zone 1 (Class I, Division 1), Zone 2 (Class I, Division 2)

- Zone 20 & 21 (Class II & III, Division 1), Zone 22 (Class II & III, Division 2)

COLOUR CODING

- Black conductor (standard)

Properties

- Stranded Bare (ASTM B8) Annealed Copper Conductor

- Semiconducting Conductor Shield

- XLPE (RW90 Rated) Insulated Conductor

- Bonding Conductor, Copper Wire Served Helically

- FR LAG PVC Inner Protective Jacket

- Aluminum Interlocked Armour (AIA)

- FR LAG PVC Outer Protective Jacket

| Part Number | Number of Conductors | Conductor Size | Bonding Conductor Size† | Nominal Diameter | Cable Weight | Ampacity* | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) | ||

| AWG or kcmil | AWG | Over Inner Wire in. | mm |

Over Armour in. | mm |

Overall Cable in. | mm |

lb/1000ft | kg/km |

30°C ambient | lb | kg | in. | mm | ||

| 85210M060105700 | 1 | 6 | 8 | 0.544 | 13.8 | 0.784 | 19.9 | 0.876 | 22.3 | 385 | 572 | 105 | 210 | 95 | 15.8 | 401 |

| 85210M040105700 | 1 | 4 | 6 | 0.643 | 16.3 | 0.883 | 22.4 | 0.975 | 24.8 | 521 | 775 | 140 | 334 | 151 | 17.6 | 446 |

| 85210M030105700 | 1 | 3 | 6 | 0.670 | 17.0 | 0.910 | 23.1 | 1.002 | 25.5 | 569 | 846 | 165 | 421 | 191 | 18.0 | 458 |

| 85210M020105700 | 1 | 2 | 6 | 0.701 | 17.8 | 0.941 | 23.9 | 1.033 | 26.2 | 627 | 934 | 190 | 531 | 241 | 18.6 | 472 |

| 85210M010145700 | 1 | 1 | 4 | 0.766 | 19.5 | 0.986 | 25.0 | 1.078 | 27.4 | 802 | 1194 | 220 | 670 | 304 | 19.4 | 493 |

| 85210M1/0145700 | 1 | 1/0 | 4 | 0.806 | 20.5 | 1.046 | 26.6 | 1.138 | 28.9 | 896 | 1334 | 260 | 845 | 383 | 20.5 | 520 |

| 85210M2/0145700 | 1 | 2/0 | 4 | 0.849 | 21.6 | 1.089 | 27.7 | 1.181 | 30.0 | 1006 | 1497 | 300 | 1065 | 483 | 21.3 | 540 |

| 85210M3/0145700 | 1 | 3/0 | 4 | 0.900 | 22.9 | 1.140 | 29.0 | 1.232 | 31.3 | 1171 | 1742 | 350 | 1336 | 606 | 22.2 | 563 |

| 85210M4/0145700 | 1 | 4/0 | 4 | 0.986 | 25.0 | 1.226 | 31.1 | 1.318 | 33.5 | 1375 | 2046 | 405 | 1693 | 768 | 23.7 | 603 |

| 85210M250165700 | 1 | 250 | 4 | 1.042 | 26.5 | 1.282 | 32.6 | 1.374 | 34.9 | 1562 | 2324 | 455 | 2000 | 907 | 24.7 | 628 |

| 85210M300165700 | 1 | 300 | 4 | 1.095 | 27.8 | 1.335 | 33.9 | 1.427 | 36.3 | 1747 | 2599 | 500 | 2400 | 1089 | 25.7 | 652 |

| 85210M350165700 | 1 | 350 | 4 | 1.145 | 29.1 | 1.385 | 35.2 | 1.477 | 37.5 | 1986 | 2955 | 570 | 2800 | 1270 | 26.6 | 675 |

| 85210M500165700 | 1 | 500 | 4 | 1.273 | 32.3 | 1.513 | 38.4 | 1.605 | 40.8 | 2594 | 3861 | 700 | 4000 | 1814 | 28.9 | 734 |

| 85210M750165700 | 1 | 750 | 4 | 1.460 | 37.1 | 1.700 | 43.2 | 1.808 | 45.9 | 3615 | 5379 | 885 | 6000 | 2722 | 32.5 | 827 |

*Ampacity value based on Canadian Electrical Code, Part 1 (2021 25th Edition), Table 1.

†The size of the concentrically applied bonding conductor shall be determined from the sum of the cross-sectional areas of the individual wires.

Markets / Applications

- Water/Waste Water Treatment

- Industrial

- Petrochem/Pulp & Paper

- Mining

VOLTAGE

5000 V

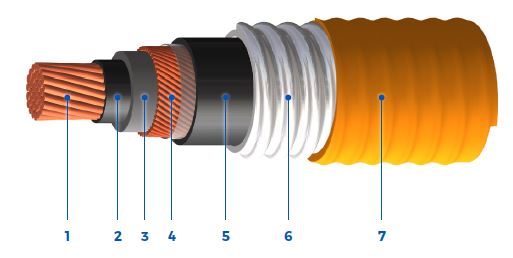

PRODUCT CONSTRUCTION

Conductor Shield:

Extruded, concentric, thermoset semiconducting material

Insulation:

XLPE (RW90 rated) rated: 90°C wet/105°C dry

Bonding Conductor:

Concentric serving of solid bare copper wires applied over the insulation

Armour:

Aluminum Interlocked Armour (AIA) (standard)

Jacket:

FR LAG PVC (AG14 rated) inner black jacket rated: 90°C to -40°C

FR LAG PVC (AG14 rated) outer orange jacket rated: 90°C to -40°C

Available in:

Ribbed inner-jacketed core for vertical/mineshaft applications

Custom insulation / jacket colours

Aluminum conductors

Certifications/Compliances

- CSA C22.2 No. 131, Type TECK 90 cable

- CSA C22.2 No. 174, Cables and cable glands for use in hazardous locations

- CSA C22.2 No. 38, Thermoset-insulated wires and cables

- CSA C22.2 No. 2556/UL 2556 FT4, Vertical Tray Flame Test rated

- IEEE 383/1202 (70,000 BTU/hr), Vertical Flame Test rated

- XLPE (RW90 rated), 90°C wet/dry

- UV sunlight resistant “SUN RES” (all colours)

- Direct burial rated

- -40°C cold bend/impact rated

- HL rated for use in hazardous locations:

- Zone 0 (Class 1, Division 1) (Intrinsically Safe circuits only)

- Zone 1 (Class I, Division 1), Zone 2 (Class I, Division 2)

- Zone 20 & 21 (Class II & III, Division 1), Zone 22 (Class II & III, Division 2)

COLOUR CODING

- Black conductor (standard)

- Stranded Bare (ASTM B8) Annealed Copper Conductor

- Semiconducting Conductor Shield

- XLPE (RW90 Rated) Insulated Conductor

- Bonding Conductor, Copper Wire Served Helically

- FR LAG PVC Inner Protective Jacket

- Aluminum Interlocked Armour (AIA)

- FR LAG PVC Outer Protective Jacket

| Part Number | Number of Conductors | Conductor Size | Bonding Conductor Size† | Nominal Diameter | Cable Weight | Ampacity* | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) | ||

| AWG or kcmil | AWG | Over Inner Wire in. | mm |

Over Armour in. | mm |

Overall Cable in. | mm |

lb/1000ft | kg/km |

30°C ambient | lb | kg | in. | mm | ||

| 85210M060105700 | 1 | 6 | 8 | 0.544 | 13.8 | 0.784 | 19.9 | 0.876 | 22.3 | 385 | 572 | 105 | 210 | 95 | 15.8 | 401 |

| 85210M040105700 | 1 | 4 | 6 | 0.643 | 16.3 | 0.883 | 22.4 | 0.975 | 24.8 | 521 | 775 | 140 | 334 | 151 | 17.6 | 446 |

| 85210M030105700 | 1 | 3 | 6 | 0.670 | 17.0 | 0.910 | 23.1 | 1.002 | 25.5 | 569 | 846 | 165 | 421 | 191 | 18.0 | 458 |

| 85210M020105700 | 1 | 2 | 6 | 0.701 | 17.8 | 0.941 | 23.9 | 1.033 | 26.2 | 627 | 934 | 190 | 531 | 241 | 18.6 | 472 |

| 85210M010145700 | 1 | 1 | 4 | 0.766 | 19.5 | 0.986 | 25.0 | 1.078 | 27.4 | 802 | 1194 | 220 | 670 | 304 | 19.4 | 493 |

| 85210M1/0145700 | 1 | 1/0 | 4 | 0.806 | 20.5 | 1.046 | 26.6 | 1.138 | 28.9 | 896 | 1334 | 260 | 845 | 383 | 20.5 | 520 |

| 85210M2/0145700 | 1 | 2/0 | 4 | 0.849 | 21.6 | 1.089 | 27.7 | 1.181 | 30.0 | 1006 | 1497 | 300 | 1065 | 483 | 21.3 | 540 |

| 85210M3/0145700 | 1 | 3/0 | 4 | 0.900 | 22.9 | 1.140 | 29.0 | 1.232 | 31.3 | 1171 | 1742 | 350 | 1336 | 606 | 22.2 | 563 |

| 85210M4/0145700 | 1 | 4/0 | 4 | 0.986 | 25.0 | 1.226 | 31.1 | 1.318 | 33.5 | 1375 | 2046 | 405 | 1693 | 768 | 23.7 | 603 |

| 85210M250165700 | 1 | 250 | 4 | 1.042 | 26.5 | 1.282 | 32.6 | 1.374 | 34.9 | 1562 | 2324 | 455 | 2000 | 907 | 24.7 | 628 |

| 85210M300165700 | 1 | 300 | 4 | 1.095 | 27.8 | 1.335 | 33.9 | 1.427 | 36.3 | 1747 | 2599 | 500 | 2400 | 1089 | 25.7 | 652 |

| 85210M350165700 | 1 | 350 | 4 | 1.145 | 29.1 | 1.385 | 35.2 | 1.477 | 37.5 | 1986 | 2955 | 570 | 2800 | 1270 | 26.6 | 675 |

| 85210M500165700 | 1 | 500 | 4 | 1.273 | 32.3 | 1.513 | 38.4 | 1.605 | 40.8 | 2594 | 3861 | 700 | 4000 | 1814 | 28.9 | 734 |

| 85210M750165700 | 1 | 750 | 4 | 1.460 | 37.1 | 1.700 | 43.2 | 1.808 | 45.9 | 3615 | 5379 | 885 | 6000 | 2722 | 32.5 | 827 |

*Ampacity value based on Canadian Electrical Code, Part 1 (2021 25th Edition), Table 1.

†The size of the concentrically applied bonding conductor shall be determined from the sum of the cross-sectional areas of the individual wires.

- Water/Waste Water Treatment

- Industrial

- Petrochem/Pulp & Paper

- Mining