CSA ACIC Armoured Thermocouple Extension | Pairs (300V)

Shawflex Thermocouple Extension cables offer advantages in cost and mechanical properties when used for connections between thermocouples and instruments.

Construction

Voltage

300 V

Optional: 600V

Product Construction

- Insulation: – XLPE (RW90 rated) rated: 90°C wet/ 105°C dry

- Shielding (foil-free edge): – ISOS (standard) – OS (optional)

- Armour: – Aluminum Interlocked Armour (AIA) (standard) – Steel Interlocked Armour (SIA) (optional) – Served Wire Armour (SWA) (optional)

- Jacket: – FR PVC inner black jacket (standard) rated: 90°C to -40°C

– FR PVC outer jacket (see Colour Coding for standard colours) rated: 90°C to -40°C - Available in: – Composite constructions

– Custom insulation/jacket colours – Extension cables for type E, J, K, N, R, S and T thermocouple alloys

Certifications

Certifications/Compliances

- CSA C22.2 NO. 239, Control & Instrumentation Cables (Type ACIC)

- CSA C22.2 NO. 174, Cables & Cable Glands for use in Hazardous Locations

- CSA C22.2 NO. 38. Thermoset Insulated Wires & Cables (XLPE)

- CSA FT4, UL 1685 FT4, Vertical Tray Flame Test rated

- IEEE 383 & 1202 (70,000 BTU/hr), Vertical Flame Test rated

- ICEA T-30-520 (70,000 BTU/hr), Vertical Flame Test rated

- XLPE (RW90 rated), 90°C wet/ 105°C dry

- UV sunlight resistant “SUN RES” (all colours)

- Direct burial rated

- -40°C cold bend/impact rated

- HL rated for use in hazardous locations:

- Class 1 Zone 0 (Intrinsically Safe cables only)

- Class 1 Zone 1 (Div 1)

- Class I Zone 2 (Div 2)

- HL-BCD gas groups rated

Colour Coding

- Type EX: (+) Purple (-) Red Purple jacket

- Type JX: (+) White (-) Red Black jacket

- Type KX: (+) Yellow (-) Red Yellow jacket

- Type NX: (+) Orange (-) Red Orange jacket

- Type RX/SX: (+) Black (-) Red Green jacket

- Type TX: (+) Blue (-) Red Blue jacket

Properties

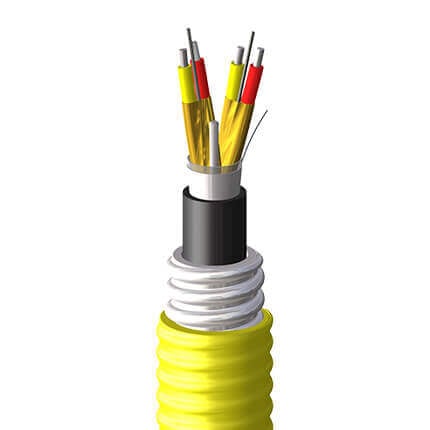

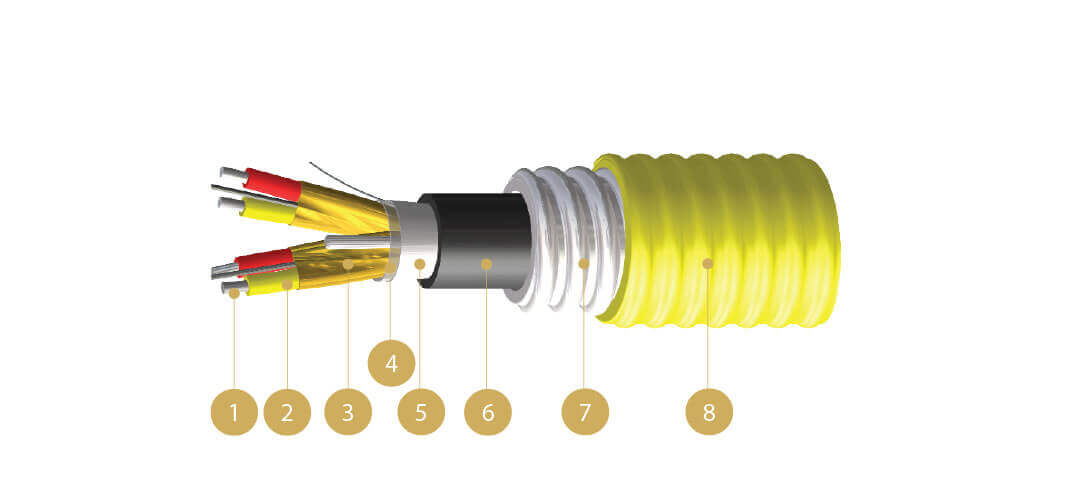

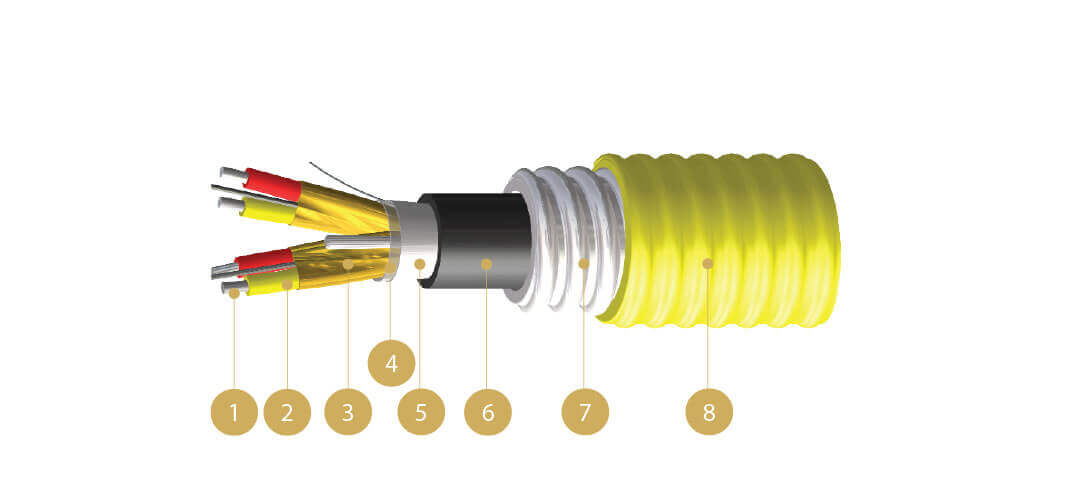

- Thermocouple Alloys

- Insulated Thermocouple Alloy Wires

- Individual Aluminum / Mylar Shielded Pairs with Tinned Copper Drain Wire

- Polyester Separator Tape

- Overall Aluminum / Mylar Shield with Tinned Copper Drain Wire

- FR PVC Black Inner Protective Jacket

- Aluminum Interlocked Armour (AIA)

- FR PVC Yellow Outer Protective Jacket

| Part Number | Number of Pairs | Conductor Size (AWG/MCM) | OD Over Inner Jacket (in/mm) | Nominal Diameters | Cable Weight (lbs/1000ft)/(kg/km) | Max. Pulling Tension (Pulling Eye) (lb/kg) | Min. Bend Radius (Pull) (in/mm) | |

| Over Armour (in/mm) | Overall Cable (in/mm) | |||||||

| 74221M1601XY700 | 1 | 16 | 0.313 / 7.95 | 0.553 / 14.05 | 0.665 / 16.89 | 176 / 262 | 41 / 19 | 12 / 304 |

| 74222M1602XY700 | 2 | 16 | 0.458 / 11.64 | 0.698 / 17.74 | 0.81 / 20.58 | 266 / 396 | 82 / 37 | 14.6 / 371 |

| 74222M1604XY700 | 4 | 16 | 0.534 / 13.57 | 0.774 / 19.66 | 0.886 / 22.51 | 333 / 495 | 165 / 75 | 15.9 / 405 |

| 74222M1606XY700 | 6 | 16 | 0.671 / 17.04 | 0.911 / 23.14 | 1.023 / 25.98 | 449 / 669 | 247 / 112 | 18.4 / 468 |

| 74222M1608XY700 | 8 | 16 | 0.727 / 18.46 | 0.967 / 24.55 | 1.079 / 27.4 | 518 / 771 | 330 / 150 | 19.4 / 493 |

| 74222M1612XY700 | 12 | 16 | 0.922 / 23.42 | 1.162 / 29.52 | 1.274 / 32.36 | 770 / 1145 | 494 / 224 | 22.9 / 583 |

| 74222M1624XY700 | 24 | 16 | 1.264 / 32.1 | 1.504 / 38.2 | 1.616 / 41.04 | 1220 / 1816 | 989 / 449 | 29.1 / 739 |

| 74221M1801XY700 | 1 | 18 | 0.291 / 7.39 | 0.531 / 13.49 | 0.643 / 16.33 | 162 / 241 | 26 / 12 | 11.6 / 294 |

| 74222M1802XY700 | 2 | 18 | 0.422 / 10.72 | 0.662 / 16.82 | 0.774 / 19.66 | 240 / 357 | 52 / 24 | 13.9 / 354 |

| 74222M1804XY700 | 4 | 18 | 0.49 / 12.45 | 0.73 / 18.54 | 0.842 / 21.39 | 289 / 430 | 104 / 47 | 15.2 / 385 |

| 74222M1806XY700 | 6 | 18 | 0.616 / 15.64 | 0.856 / 21.74 | 0.968 / 24.58 | 386 / 574 | 156 / 71 | 17.4 / 442 |

| 74222M1808XY700 | 8 | 18 | 0.666 / 16.91 | 0.906 / 23 | 1.018 / 25.85 | 438 / 651 | 208 / 94 | 18.3 / 465 |

| 74222M1812XY700 | 12 | 18 | 0.805 / 20.44 | 1.045 / 26.54 | 1.157 / 29.39 | 606 / 902 | 312 / 142 | 20.8 / 529 |

| 74222M1824XY700 | 24 | 18 | 1.151 / 29.24 | 1.391 / 35.33 | 1.503 / 38.18 | 1002 / 1490 | 624 / 283 | 27.1 / 687 |

| 74221M2001XY700 | 1 | 20 | 0.275 / 6.98 | 0.515 / 13.08 | 0.627 / 15.93 | 153 / 227 | 16 / 7 | 11.3 / 287 |

| 74222M2002XY700 | 2 | 20 | 0.396 / 10.05 | 0.636 / 16.15 | 0.748 / 18.99 | 220 / 328 | 32 / 15 | 13.5 / 342 |

| 74222M2004XY700 | 4 | 20 | 0.458 / 11.63 | 0.698 / 17.73 | 0.81 / 20.57 | 261 / 389 | 64 / 29 | 14.6 / 370 |

| 74222M2006XY700 | 6 | 20 | 0.576 / 14.62 | 0.816 / 20.72 | 0.928 / 23.56 | 345 / 513 | 96 / 44 | 16.7 / 424 |

| 74222M2008XY700 | 8 | 20 | 0.621 / 15.78 | 0.861 / 21.87 | 0.973 / 24.72 | 387 / 575 | 128 / 58 | 17.5 / 445 |

| 74222M2012XY700 | 12 | 20 | 0.749 / 19.02 | 0.989 / 25.11 | 1.101 / 27.96 | 489 / 728 | 192 / 87 | 19.8 / 503 |

| 74222M2024XY700 | 24 | 20 | 1.069 / 27.15 | 1.309 / 33.25 | 1.421 / 36.09 | 861 / 1281 | 384 / 174 | 25.6 / 650 |

Markets / Applications

- Generation – Renewables – Wind

- Transit

- Water/Waste Water Treatment

- Generation – Traditional Power

- Generation

- Communication Power & Control

- Generation – Nuclear

- Power Distribution

- Industrial Construction/Automation

- Civil Construction Projects

- Power Distribution – LV

- Industrial

- Generation – Renewables

- Petrochem/Pulp & Paper

- Utility

- Commercial Construction Projects

- Generation – Renewables – Geo Thermal

- Generation – Renewables – Solar

- Mining

Voltage

300 V

Optional: 600V

Product Construction

- Insulation: – XLPE (RW90 rated) rated: 90°C wet/ 105°C dry

- Shielding (foil-free edge): – ISOS (standard) – OS (optional)

- Armour: – Aluminum Interlocked Armour (AIA) (standard) – Steel Interlocked Armour (SIA) (optional) – Served Wire Armour (SWA) (optional)

- Jacket: – FR PVC inner black jacket (standard) rated: 90°C to -40°C

– FR PVC outer jacket (see Colour Coding for standard colours) rated: 90°C to -40°C - Available in: – Composite constructions

– Custom insulation/jacket colours – Extension cables for type E, J, K, N, R, S and T thermocouple alloys

Certifications/Compliances

- CSA C22.2 NO. 239, Control & Instrumentation Cables (Type ACIC)

- CSA C22.2 NO. 174, Cables & Cable Glands for use in Hazardous Locations

- CSA C22.2 NO. 38. Thermoset Insulated Wires & Cables (XLPE)

- CSA FT4, UL 1685 FT4, Vertical Tray Flame Test rated

- IEEE 383 & 1202 (70,000 BTU/hr), Vertical Flame Test rated

- ICEA T-30-520 (70,000 BTU/hr), Vertical Flame Test rated

- XLPE (RW90 rated), 90°C wet/ 105°C dry

- UV sunlight resistant “SUN RES” (all colours)

- Direct burial rated

- -40°C cold bend/impact rated

- HL rated for use in hazardous locations:

- Class 1 Zone 0 (Intrinsically Safe cables only)

- Class 1 Zone 1 (Div 1)

- Class I Zone 2 (Div 2)

- HL-BCD gas groups rated

Colour Coding

- Type EX: (+) Purple (-) Red Purple jacket

- Type JX: (+) White (-) Red Black jacket

- Type KX: (+) Yellow (-) Red Yellow jacket

- Type NX: (+) Orange (-) Red Orange jacket

- Type RX/SX: (+) Black (-) Red Green jacket

- Type TX: (+) Blue (-) Red Blue jacket

- Thermocouple Alloys

- Insulated Thermocouple Alloy Wires

- Individual Aluminum / Mylar Shielded Pairs with Tinned Copper Drain Wire

- Polyester Separator Tape

- Overall Aluminum / Mylar Shield with Tinned Copper Drain Wire

- FR PVC Black Inner Protective Jacket

- Aluminum Interlocked Armour (AIA)

- FR PVC Yellow Outer Protective Jacket

| Part Number | Number of Pairs | Conductor Size (AWG/MCM) | OD Over Inner Jacket (in/mm) | Nominal Diameters | Cable Weight (lbs/1000ft)/(kg/km) | Max. Pulling Tension (Pulling Eye) (lb/kg) | Min. Bend Radius (Pull) (in/mm) | |

| Over Armour (in/mm) | Overall Cable (in/mm) | |||||||

| 74221M1601XY700 | 1 | 16 | 0.313 / 7.95 | 0.553 / 14.05 | 0.665 / 16.89 | 176 / 262 | 41 / 19 | 12 / 304 |

| 74222M1602XY700 | 2 | 16 | 0.458 / 11.64 | 0.698 / 17.74 | 0.81 / 20.58 | 266 / 396 | 82 / 37 | 14.6 / 371 |

| 74222M1604XY700 | 4 | 16 | 0.534 / 13.57 | 0.774 / 19.66 | 0.886 / 22.51 | 333 / 495 | 165 / 75 | 15.9 / 405 |

| 74222M1606XY700 | 6 | 16 | 0.671 / 17.04 | 0.911 / 23.14 | 1.023 / 25.98 | 449 / 669 | 247 / 112 | 18.4 / 468 |

| 74222M1608XY700 | 8 | 16 | 0.727 / 18.46 | 0.967 / 24.55 | 1.079 / 27.4 | 518 / 771 | 330 / 150 | 19.4 / 493 |

| 74222M1612XY700 | 12 | 16 | 0.922 / 23.42 | 1.162 / 29.52 | 1.274 / 32.36 | 770 / 1145 | 494 / 224 | 22.9 / 583 |

| 74222M1624XY700 | 24 | 16 | 1.264 / 32.1 | 1.504 / 38.2 | 1.616 / 41.04 | 1220 / 1816 | 989 / 449 | 29.1 / 739 |

| 74221M1801XY700 | 1 | 18 | 0.291 / 7.39 | 0.531 / 13.49 | 0.643 / 16.33 | 162 / 241 | 26 / 12 | 11.6 / 294 |

| 74222M1802XY700 | 2 | 18 | 0.422 / 10.72 | 0.662 / 16.82 | 0.774 / 19.66 | 240 / 357 | 52 / 24 | 13.9 / 354 |

| 74222M1804XY700 | 4 | 18 | 0.49 / 12.45 | 0.73 / 18.54 | 0.842 / 21.39 | 289 / 430 | 104 / 47 | 15.2 / 385 |

| 74222M1806XY700 | 6 | 18 | 0.616 / 15.64 | 0.856 / 21.74 | 0.968 / 24.58 | 386 / 574 | 156 / 71 | 17.4 / 442 |

| 74222M1808XY700 | 8 | 18 | 0.666 / 16.91 | 0.906 / 23 | 1.018 / 25.85 | 438 / 651 | 208 / 94 | 18.3 / 465 |

| 74222M1812XY700 | 12 | 18 | 0.805 / 20.44 | 1.045 / 26.54 | 1.157 / 29.39 | 606 / 902 | 312 / 142 | 20.8 / 529 |

| 74222M1824XY700 | 24 | 18 | 1.151 / 29.24 | 1.391 / 35.33 | 1.503 / 38.18 | 1002 / 1490 | 624 / 283 | 27.1 / 687 |

| 74221M2001XY700 | 1 | 20 | 0.275 / 6.98 | 0.515 / 13.08 | 0.627 / 15.93 | 153 / 227 | 16 / 7 | 11.3 / 287 |

| 74222M2002XY700 | 2 | 20 | 0.396 / 10.05 | 0.636 / 16.15 | 0.748 / 18.99 | 220 / 328 | 32 / 15 | 13.5 / 342 |

| 74222M2004XY700 | 4 | 20 | 0.458 / 11.63 | 0.698 / 17.73 | 0.81 / 20.57 | 261 / 389 | 64 / 29 | 14.6 / 370 |

| 74222M2006XY700 | 6 | 20 | 0.576 / 14.62 | 0.816 / 20.72 | 0.928 / 23.56 | 345 / 513 | 96 / 44 | 16.7 / 424 |

| 74222M2008XY700 | 8 | 20 | 0.621 / 15.78 | 0.861 / 21.87 | 0.973 / 24.72 | 387 / 575 | 128 / 58 | 17.5 / 445 |

| 74222M2012XY700 | 12 | 20 | 0.749 / 19.02 | 0.989 / 25.11 | 1.101 / 27.96 | 489 / 728 | 192 / 87 | 19.8 / 503 |

| 74222M2024XY700 | 24 | 20 | 1.069 / 27.15 | 1.309 / 33.25 | 1.421 / 36.09 | 861 / 1281 | 384 / 174 | 25.6 / 650 |

- Generation – Renewables – Wind

- Transit

- Water/Waste Water Treatment

- Generation – Traditional Power

- Generation

- Communication Power & Control

- Generation – Nuclear

- Power Distribution

- Industrial Construction/Automation

- Civil Construction Projects

- Power Distribution – LV

- Industrial

- Generation – Renewables

- Petrochem/Pulp & Paper

- Utility

- Commercial Construction Projects

- Generation – Renewables – Geo Thermal

- Generation – Renewables – Solar

- Mining