CSA TYPE CIC RW90 TC Tray Power Control, Multi-Conductor, 1000 V

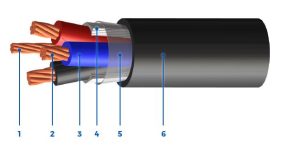

Construction

VOLTAGE

1000 V

Optional: 600, 2000 V

PRODUCT CONSTRUCTION

-

- Insulation:

- XLPE (RW90 rated) rated: 90°C wet/ 105°C dry

- Insulation:

Shielding (optional):

Aluminum/mylar film

Copper tape, helical or corrugated

Tin-coated copper braid

-

- Jacket:

- FR PVC outer black jacket rated: 90°C to -40°C

- Jacket:

- Available in:

- Custom insulation / jacket colours

- Composite constructions

- Aluminum conductors

-

COLOUR CODING

2C-Black & white

3C-Black, red & blue

4C-Black, red, blue & white

5C or greater – Black, number-coded with white ink

Certifications

CERTIFICATION/COMPLIANCES

- CSA C22.2 No. 230, Tray cables

- CSA C22.2 No. 239, Control and instrumentation cables

- CSA C22.2 No. 38, Thermoset-insulated wires and cables

- CSA C22.2 No. 2556 / UL 2556 FT4, Vertical Tray Flame Test rated

- IEEE 383/1202 (70,000 BTU/hr), Vertical Flame Test rated

- XLPE (RW90 rated), 90°C wet / 105°C dry

- UV sunlight resistant SUN RES (all colours)

- Direct burial rated

- -40°C cold bend / impact rated

- Rated for use in hazardous locations:

- Zone 0 (Class 1, Division 1) (Intrinsically Safe circuits only)

- Zone 2 (Class I, Division 2)

- Zone 22 (Class II & III, Division 2)

Properties

|

|

| Part Number | Number of Conductors | Conductor Size | Bonding Conductor Size | Nominal Diameter Overall Cable | Cable Weight | Ampacity* | Max Pulling Tension (Pulling Eye) | Min Bend Radius (Pull) |

| AWG or kcmil | AWG | in. | mm | lb|1000ft | kg|km | 30°C ambient | lb | kg | in. | mm | ||

| 4D010M140200000 | 2 | 14 | 14 | 0.432 | 11.0 | 97 | 144 | 25 | 66 | 30 | 3.9 | 99 |

| 4S010M120200000 | 2 | 12 | 14 | 0.468 | 11.9 | 120 | 179 | 30 | 104 | 47 | 4.2 | 107 |

| 4S010M100200000 | 2 | 10 | 12 | 0.518 | 13.2 | 162 | 241 | 40 | 166 | 75 | 4.7 | 118 |

| 4D010M080200000 | 2 | 8 | 10 | 0.606 | 15.4 | 245 | 364 | 55 | 265 | 120 | 5.5 | 139 |

| 4D010M060200000 | 2 | 6 | 8 | 0.744 | 18.9 | 371 | 552 | 75 | 419 | 190 | 6.7 | 170 |

| 4D010M040200000 | 2 | 4 | 8 | 0.838 | 21.3 | 502 | 747 | 95 | 668 | 303 | 7.5 | 192 |

| 4D010M030200000 | 2 | 3 | 6 | 0.932 | 23.7 | 654 | 973 | 115 | 842 | 382 | 8.4 | 213 |

| 4D010M020200000 | 2 | 2 | 6 | 0.994 | 25.3 | 763 | 1135 | 130 | 1062 | 482 | 8.9 | 227 |

| 4D010M010240000 | 2 | 1 | 6 | 1.152 | 29.3 | 959 | 1427 | 145 | 1339 | 607 | 10.4 | 263 |

| 4D010M1/0240000 | 2 | 1/0 | 6 | 1.232 | 31.3 | 1120 | 1667 | 170 | 1690 | 766 | 11.1 | 282 |

| 4D010M2/0240000 | 2 | 2/0 | 6 | 1.318 | 33.5 | 1338 | 1992 | 195 | 2130 | 966 | 11.9 | 301 |

| 4D010M3/0240000 | 2 | 3/0 | 4 | 1.420 | 36.1 | 1648 | 2452 | 225 | 2671 | 1212 | 12.8 | 325 |

| 4D010M4/0240000 | 2 | 4/0 | 4 | 1.532 | 38.9 | 1987 | 2957 | 260 | 3386 | 1536 | 13.8 | 350 |

| 4D010M250260000 | 2 | 250 | 4 | 1.664 | 42.3 | 2290 | 3408 | 290 | 4000 | 1814 | 15.0 | 380 |

| 4D010M300260000 | 2 | 300 | 4 | 1.830 | 46.5 | 2762 | 4110 | 320 | 4800 | 2177 | 16.5 | 418 |

| 4D010M350260000 | 2 | 350 | 3 | 1.930 | 49.0 | 3175 | 4725 | 350 | 5600 | 2540 | 17.4 | 441 |

| 4D010M500260000 | 2 | 500 | 3 | 2.186 | 55.5 | 4284 | 6375 | 430 | 8000 | 3629 | 19.7 | 500 |

| 4D010M750260000 | 2 | 750 | 2 | 2.544 | 64.6 | 6150 | 9152 | 535 | 12000 | 5443 | 22.9 | 582 |

| 4D010M140300000 | 3 | 14 | 14 | 0.470 | 11.9 | 119 | 177 | 25 | 99 | 45 | 4.2 | 107 |

| 4S010M120300000 | 3 | 12 | 14 | 0.510 | 13.0 | 152 | 226 | 30 | 157 | 71 | 4.6 | 117 |

| 4S010M100300000 | 3 | 10 | 12 | 0.595 | 15.1 | 223 | 332 | 40 | 249 | 113 | 5.4 | 136 |

| 4D010M080300000 | 3 | 8 | 10 | 0.660 | 16.8 | 313 | 466 | 55 | 397 | 180 | 5.9 | 151 |

| 4D010M060300000 | 3 | 6 | 8 | 0.813 | 20.7 | 481 | 716 | 75 | 629 | 285 | 7.3 | 186 |

| 4D010M040300000 | 3 | 4 | 8 | 0.930 | 23.6 | 693 | 1032 | 95 | 1002 | 454 | 8.4 | 213 |

| 4D010M030300000 | 3 | 3 | 6 | 0.988 | 25.1 | 845 | 1258 | 115 | 1263 | 573 | 8.9 | 226 |

| 4D010M020300000 | 3 | 2 | 6 | 1.055 | 26.8 | 1005 | 1496 | 130 | 1593 | 723 | 9.5 | 241 |

| 4D010M010340000 | 3 | 1 | 6 | 1.225 | 31.1 | 1264 | 1882 | 145 | 2009 | 911 | 11.0 | 280 |

| 4D010M1/0340000 | 3 | 1/0 | 6 | 1.311 | 33.3 | 1498 | 2230 | 170 | 2534 | 1150 | 11.8 | 300 |

| 4D010M2/0340000 | 3 | 2/0 | 6 | 1.403 | 35.7 | 1802 | 2681 | 195 | 3194 | 1449 | 12.6 | 321 |

| 4D010M3/0340000 | 3 | 3/0 | 4 | 1.513 | 38.4 | 2239 | 3333 | 225 | 4007 | 1818 | 13.6 | 346 |

| 4D010M4/0340000 | 3 | 4/0 | 4 | 1.633 | 41.5 | 2727 | 4058 | 260 | 5078 | 2304 | 14.7 | 373 |

| 4D010M250360000 | 3 | 250 | 4 | 1.835 | 46.6 | 3238 | 4818 | 290 | 6000 | 2722 | 16.5 | 420 |

| 4D010M300360000 | 3 | 300 | 4 | 1.949 | 49.5 | 3775 | 5618 | 320 | 7200 | 3266 | 17.5 | 446 |

| 4D010M350360000 | 3 | 350 | 3 | 2.057 | 52.2 | 4355 | 6481 | 350 | 8400 | 3810 | 18.5 | 470 |

| 4D010M500360000 | 3 | 500 | 3 | 2.332 | 59.2 | 5940 | 8839 | 430 | 12000 | 5443 | 21 | 533 |

| 4D010M750360000 | 3 | 750 | 3 | 2.717 | 69.0 | 8586 | 12778 | 535 | 18000 | 8165 | 24.5 | 621 |

| 4D010M140400000 | 4 | 14 | 14 | 0.510 | 13.0 | 143 | 213 | 20 | 132 | 60 | 4.6 | 117 |

| 4S010M120400000 | 4 | 12 | 14 | 0.585 | 14.9 | 202 | 301 | 24 | 209 | 95 | 5.3 | 134 |

| 4S010M100400000 | 4 | 10 | 12 | 0.647 | 16.4 | 274 | 407 | 32 | 332 | 151 | 5.8 | 148 |

| 4D010M080400000 | 4 | 8 | 10 | 0.719 | 18.3 | 386 | 574 | 44 | 529 | 240 | 6.5 | 164 |

| 4D010M060400000 | 4 | 6 | 8 | 0.929 | 23.6 | 631 | 939 | 60 | 839 | 380 | 8.4 | 212 |

| 4D010M040400000 | 4 | 4 | 8 | 1.045 | 26.6 | 872 | 1298 | 76 | 1336 | 606 | 9.4 | 239 |

| 4D010M030400000 | 4 | 3 | 6 | 1.112 | 28.3 | 1069 | 1590 | 92 | 1684 | 764 | 10.0 | 254 |

| 4D010M020400000 | 4 | 2 | 6 | 1.189 | 30.2 | 1280 | 1904 | 104 | 2124 | 964 | 10.7 | 272 |

| 4D010M010440000 | 4 | 1 | 6 | 1.351 | 34.3 | 1614 | 2402 | 116 | 2678 | 1215 | 12.2 | 309 |

| 4D010M1/0440000 | 4 | 1/0 | 6 | 1.448 | 36.8 | 1911 | 2844 | 136 | 3379 | 1533 | 13.0 | 331 |

| 4D010M2/0440000 | 4 | 2/0 | 6 | 1.551 | 39.4 | 2339 | 3481 | 156 | 4259 | 1932 | 14.0 | 355 |

| 4D010M3/0440000 | 4 | 3/0 | 4 | 1.674 | 42.5 | 2877 | 4282 | 180 | 5343 | 2423 | 15.1 | 383 |

| 4D010M4/0440000 | 4 | 4/0 | 4 | 1.869 | 47.5 | 3632 | 5405 | 208 | 6771 | 3071 | 16.8 | 427 |

| 4D010M250460000 | 4 | 250 | 4 | 2.028 | 51.5 | 4174 | 6212 | 232 | 8000 | 3629 | 18.3 | 464 |

| 4D010M300460000 | 4 | 300 | 4 | 2.156 | 54.8 | 4899 | 7290 | 256 | 9600 | 4355 | 19.4 | 493 |

| 4D010M350460000 | 4 | 350 | 3 | 2.276 | 57.8 | 5627 | 8374 | 280 | 11200 | 5080 | 20.5 | 520 |

| 4D010M500460000 | 4 | 500 | 3 | 2.585 | 65.7 | 7737 | 11514 | 344 | 16000 | 7258 | 23.3 | 591 |

| 4D010M750460000 | 4 | 750 | 2 | 3.076 | 78.1 | 11373 | 16925 | 428 | 24000 | 10886 | 27.7 | 703 |

*Ampacity value based on Canadian Electrical Code, Part 1 (2021 25th Edition), Table 2. Values are corrected for number of insulated conductors as applicable according to Table 5C.

Markets / Applications

- Energy

- Industrial

- Industrial Construction/Automation

- Petrochem/Pulp & Paper

- Power Distribution

- Power Distribution – LV

- Utility

- Water/Waste Water Treatment

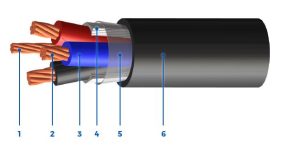

VOLTAGE

1000 V

Optional: 600, 2000 V

PRODUCT CONSTRUCTION

-

- Insulation:

- XLPE (RW90 rated) rated: 90°C wet/ 105°C dry

- Insulation:

Shielding (optional):

Aluminum/mylar film

Copper tape, helical or corrugated

Tin-coated copper braid

-

- Jacket:

- FR PVC outer black jacket rated: 90°C to -40°C

- Jacket:

- Available in:

- Custom insulation / jacket colours

- Composite constructions

- Aluminum conductors

-

COLOUR CODING

2C-Black & white

3C-Black, red & blue

4C-Black, red, blue & white

5C or greater – Black, number-coded with white ink

CERTIFICATION/COMPLIANCES

- CSA C22.2 No. 230, Tray cables

- CSA C22.2 No. 239, Control and instrumentation cables

- CSA C22.2 No. 38, Thermoset-insulated wires and cables

- CSA C22.2 No. 2556 / UL 2556 FT4, Vertical Tray Flame Test rated

- IEEE 383/1202 (70,000 BTU/hr), Vertical Flame Test rated

- XLPE (RW90 rated), 90°C wet / 105°C dry

- UV sunlight resistant SUN RES (all colours)

- Direct burial rated

- -40°C cold bend / impact rated

- Rated for use in hazardous locations:

- Zone 0 (Class 1, Division 1) (Intrinsically Safe circuits only)

- Zone 2 (Class I, Division 2)

- Zone 22 (Class II & III, Division 2)

|

|

| Part Number | Number of Conductors | Conductor Size | Bonding Conductor Size | Nominal Diameter Overall Cable | Cable Weight | Ampacity* | Max Pulling Tension (Pulling Eye) | Min Bend Radius (Pull) |

| AWG or kcmil | AWG | in. | mm | lb|1000ft | kg|km | 30°C ambient | lb | kg | in. | mm | ||

| 4D010M140200000 | 2 | 14 | 14 | 0.432 | 11.0 | 97 | 144 | 25 | 66 | 30 | 3.9 | 99 |

| 4S010M120200000 | 2 | 12 | 14 | 0.468 | 11.9 | 120 | 179 | 30 | 104 | 47 | 4.2 | 107 |

| 4S010M100200000 | 2 | 10 | 12 | 0.518 | 13.2 | 162 | 241 | 40 | 166 | 75 | 4.7 | 118 |

| 4D010M080200000 | 2 | 8 | 10 | 0.606 | 15.4 | 245 | 364 | 55 | 265 | 120 | 5.5 | 139 |

| 4D010M060200000 | 2 | 6 | 8 | 0.744 | 18.9 | 371 | 552 | 75 | 419 | 190 | 6.7 | 170 |

| 4D010M040200000 | 2 | 4 | 8 | 0.838 | 21.3 | 502 | 747 | 95 | 668 | 303 | 7.5 | 192 |

| 4D010M030200000 | 2 | 3 | 6 | 0.932 | 23.7 | 654 | 973 | 115 | 842 | 382 | 8.4 | 213 |

| 4D010M020200000 | 2 | 2 | 6 | 0.994 | 25.3 | 763 | 1135 | 130 | 1062 | 482 | 8.9 | 227 |

| 4D010M010240000 | 2 | 1 | 6 | 1.152 | 29.3 | 959 | 1427 | 145 | 1339 | 607 | 10.4 | 263 |

| 4D010M1/0240000 | 2 | 1/0 | 6 | 1.232 | 31.3 | 1120 | 1667 | 170 | 1690 | 766 | 11.1 | 282 |

| 4D010M2/0240000 | 2 | 2/0 | 6 | 1.318 | 33.5 | 1338 | 1992 | 195 | 2130 | 966 | 11.9 | 301 |

| 4D010M3/0240000 | 2 | 3/0 | 4 | 1.420 | 36.1 | 1648 | 2452 | 225 | 2671 | 1212 | 12.8 | 325 |

| 4D010M4/0240000 | 2 | 4/0 | 4 | 1.532 | 38.9 | 1987 | 2957 | 260 | 3386 | 1536 | 13.8 | 350 |

| 4D010M250260000 | 2 | 250 | 4 | 1.664 | 42.3 | 2290 | 3408 | 290 | 4000 | 1814 | 15.0 | 380 |

| 4D010M300260000 | 2 | 300 | 4 | 1.830 | 46.5 | 2762 | 4110 | 320 | 4800 | 2177 | 16.5 | 418 |

| 4D010M350260000 | 2 | 350 | 3 | 1.930 | 49.0 | 3175 | 4725 | 350 | 5600 | 2540 | 17.4 | 441 |

| 4D010M500260000 | 2 | 500 | 3 | 2.186 | 55.5 | 4284 | 6375 | 430 | 8000 | 3629 | 19.7 | 500 |

| 4D010M750260000 | 2 | 750 | 2 | 2.544 | 64.6 | 6150 | 9152 | 535 | 12000 | 5443 | 22.9 | 582 |

| 4D010M140300000 | 3 | 14 | 14 | 0.470 | 11.9 | 119 | 177 | 25 | 99 | 45 | 4.2 | 107 |

| 4S010M120300000 | 3 | 12 | 14 | 0.510 | 13.0 | 152 | 226 | 30 | 157 | 71 | 4.6 | 117 |

| 4S010M100300000 | 3 | 10 | 12 | 0.595 | 15.1 | 223 | 332 | 40 | 249 | 113 | 5.4 | 136 |

| 4D010M080300000 | 3 | 8 | 10 | 0.660 | 16.8 | 313 | 466 | 55 | 397 | 180 | 5.9 | 151 |

| 4D010M060300000 | 3 | 6 | 8 | 0.813 | 20.7 | 481 | 716 | 75 | 629 | 285 | 7.3 | 186 |

| 4D010M040300000 | 3 | 4 | 8 | 0.930 | 23.6 | 693 | 1032 | 95 | 1002 | 454 | 8.4 | 213 |

| 4D010M030300000 | 3 | 3 | 6 | 0.988 | 25.1 | 845 | 1258 | 115 | 1263 | 573 | 8.9 | 226 |

| 4D010M020300000 | 3 | 2 | 6 | 1.055 | 26.8 | 1005 | 1496 | 130 | 1593 | 723 | 9.5 | 241 |

| 4D010M010340000 | 3 | 1 | 6 | 1.225 | 31.1 | 1264 | 1882 | 145 | 2009 | 911 | 11.0 | 280 |

| 4D010M1/0340000 | 3 | 1/0 | 6 | 1.311 | 33.3 | 1498 | 2230 | 170 | 2534 | 1150 | 11.8 | 300 |

| 4D010M2/0340000 | 3 | 2/0 | 6 | 1.403 | 35.7 | 1802 | 2681 | 195 | 3194 | 1449 | 12.6 | 321 |

| 4D010M3/0340000 | 3 | 3/0 | 4 | 1.513 | 38.4 | 2239 | 3333 | 225 | 4007 | 1818 | 13.6 | 346 |

| 4D010M4/0340000 | 3 | 4/0 | 4 | 1.633 | 41.5 | 2727 | 4058 | 260 | 5078 | 2304 | 14.7 | 373 |

| 4D010M250360000 | 3 | 250 | 4 | 1.835 | 46.6 | 3238 | 4818 | 290 | 6000 | 2722 | 16.5 | 420 |

| 4D010M300360000 | 3 | 300 | 4 | 1.949 | 49.5 | 3775 | 5618 | 320 | 7200 | 3266 | 17.5 | 446 |

| 4D010M350360000 | 3 | 350 | 3 | 2.057 | 52.2 | 4355 | 6481 | 350 | 8400 | 3810 | 18.5 | 470 |

| 4D010M500360000 | 3 | 500 | 3 | 2.332 | 59.2 | 5940 | 8839 | 430 | 12000 | 5443 | 21 | 533 |

| 4D010M750360000 | 3 | 750 | 3 | 2.717 | 69.0 | 8586 | 12778 | 535 | 18000 | 8165 | 24.5 | 621 |

| 4D010M140400000 | 4 | 14 | 14 | 0.510 | 13.0 | 143 | 213 | 20 | 132 | 60 | 4.6 | 117 |

| 4S010M120400000 | 4 | 12 | 14 | 0.585 | 14.9 | 202 | 301 | 24 | 209 | 95 | 5.3 | 134 |

| 4S010M100400000 | 4 | 10 | 12 | 0.647 | 16.4 | 274 | 407 | 32 | 332 | 151 | 5.8 | 148 |

| 4D010M080400000 | 4 | 8 | 10 | 0.719 | 18.3 | 386 | 574 | 44 | 529 | 240 | 6.5 | 164 |

| 4D010M060400000 | 4 | 6 | 8 | 0.929 | 23.6 | 631 | 939 | 60 | 839 | 380 | 8.4 | 212 |

| 4D010M040400000 | 4 | 4 | 8 | 1.045 | 26.6 | 872 | 1298 | 76 | 1336 | 606 | 9.4 | 239 |

| 4D010M030400000 | 4 | 3 | 6 | 1.112 | 28.3 | 1069 | 1590 | 92 | 1684 | 764 | 10.0 | 254 |

| 4D010M020400000 | 4 | 2 | 6 | 1.189 | 30.2 | 1280 | 1904 | 104 | 2124 | 964 | 10.7 | 272 |

| 4D010M010440000 | 4 | 1 | 6 | 1.351 | 34.3 | 1614 | 2402 | 116 | 2678 | 1215 | 12.2 | 309 |

| 4D010M1/0440000 | 4 | 1/0 | 6 | 1.448 | 36.8 | 1911 | 2844 | 136 | 3379 | 1533 | 13.0 | 331 |

| 4D010M2/0440000 | 4 | 2/0 | 6 | 1.551 | 39.4 | 2339 | 3481 | 156 | 4259 | 1932 | 14.0 | 355 |

| 4D010M3/0440000 | 4 | 3/0 | 4 | 1.674 | 42.5 | 2877 | 4282 | 180 | 5343 | 2423 | 15.1 | 383 |

| 4D010M4/0440000 | 4 | 4/0 | 4 | 1.869 | 47.5 | 3632 | 5405 | 208 | 6771 | 3071 | 16.8 | 427 |

| 4D010M250460000 | 4 | 250 | 4 | 2.028 | 51.5 | 4174 | 6212 | 232 | 8000 | 3629 | 18.3 | 464 |

| 4D010M300460000 | 4 | 300 | 4 | 2.156 | 54.8 | 4899 | 7290 | 256 | 9600 | 4355 | 19.4 | 493 |

| 4D010M350460000 | 4 | 350 | 3 | 2.276 | 57.8 | 5627 | 8374 | 280 | 11200 | 5080 | 20.5 | 520 |

| 4D010M500460000 | 4 | 500 | 3 | 2.585 | 65.7 | 7737 | 11514 | 344 | 16000 | 7258 | 23.3 | 591 |

| 4D010M750460000 | 4 | 750 | 2 | 3.076 | 78.1 | 11373 | 16925 | 428 | 24000 | 10886 | 27.7 | 703 |

*Ampacity value based on Canadian Electrical Code, Part 1 (2021 25th Edition), Table 2. Values are corrected for number of insulated conductors as applicable according to Table 5C.

- Energy

- Industrial

- Industrial Construction/Automation

- Petrochem/Pulp & Paper

- Power Distribution

- Power Distribution – LV

- Utility

- Water/Waste Water Treatment