UL Type PLTC / ITC Armored Thermocouple Extension, 300 V

Shawflex Thermocouple Extension cables offer advantages in cost and mechanical properties when used for connections between thermocouples and instruments.

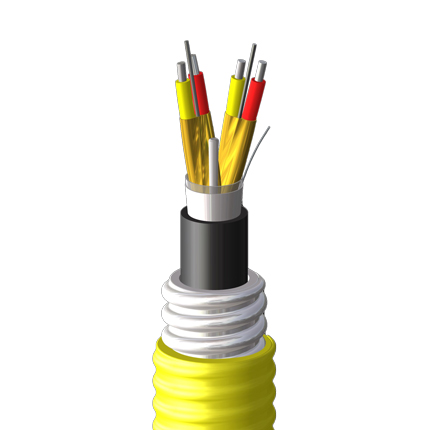

Construction

Voltage

300 V

Product Construction

-

- Insulation:

- FR PVC rated: 60°C wet / 105°C dry

- XLPE rated (optional)

- VW-1 rated (optional)

- Insulation:

-

- Shielding (foil-free edge):

- ISOS (standard)

- OS (optional)

- Shielding (foil-free edge):

-

- Armor:

- Aluminum Interlocked Armor (AIA) (standard)

- Steel Interlocked Armor (SIA) (optional)

- Served Wire Armor (SWA) (optional)

- Armor:

-

- Jacket:

- FR PVC yellow (standard) dependent on requested thermocouple alloy rated: 90°C to -40°C

- Thermoset CPE (optional)

- Thermoplastic CPE (optional)

- Thermoplastic LSZH (optional)

- Jacket:

- Available in:

- Composite constructions

- Custom insulation / jacket colors

- PLTC/ITC-ER with CPE jackets

- Extension cables for type E, J, K, N, R, S and T thermocouple alloys

Colour Coding

- Type EX: (+) Purple (-) Red Purple jacket

- Type JX: (+) White (-) Red Black jacket

- Type KX: (+) Yellow (-) Red Yellow jacket

- Type NX: (+) Orange (-) Red Orange jacket

- Type RX/SX: (+) Black (-) Red Green jacket

- Type TX: (+) Blue (-) Red Blue jacket

Certifications

Certifications/Compliances

- UL 13, Power Limited Tray Cable (PLTC)

- UL 2250, Instrumentation Tray Cable (ITC)

- UL 83, Thermoplastic Insulated Wires and Cables

- IEEE 1202 / 383 (70,000 BTU / hr), Vertical Flame Test rated (optional)

- UL 1685 / FT4, Vertical Tray Flame Test rated (optional)

- ICEA T-30-520 (70,000 BTU / hr), Vertical Flame Test rated

- UV sunlight resistant “SUN RES” (all colours)

- -40°C cold bend rated

- Rated for use in hazardous locations:

- Class I Zone 2 (Div 2)

- Class II Zone 22 (Div 2)

Properties

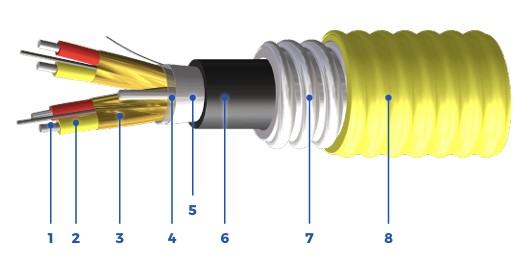

- Thermocouple Alloys

- FR PVC insulated Thermocouple Alloy Wires

- Individual Aluminum / Mylar Shielded Pairs with Tin-coated Copper Drain Wire

- Polyester Separator Tape

- Overall Aluminum / Mylar Shield with Tin-coated Copper Drain Wire

- FR PVC Black Inner Protective Jacket

- Aluminum Interlocked Armor (AIA)

- FR PVC Yellow Outer Protective Jacket

| Part Number | Number of Pairs | Conductor Size | OD Over Inner Jacket | Nominal Diameters | Cable Weight | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) | |

| Over Armour | Overall Cable | |||||||

| (AWG/kcmil) | (in/mm) | (in/mm) | (in/mm) | (lbs/1000ft)/(kg/km) | (lb/kg) | (in/mm) | ||

| 7P621U160147700 | 1 | 16 | 0.257 / 6.5 | 0.497 / 12.6 | 0.609 / 15.5 | 155 / 230 | 41 / 19 | 11 / 278 |

| 7P622U160247700 | 2 | 16 | 0.389 / 9.9 | 0.629 / 16 | 0.741 / 18.8 | 238 / 354 | 82 / 37 | 13.3 / 339 |

| 7P622U160447700 | 4 | 16 | 0.472 / 12.0 | 0.712 / 18.1 | 0.824 / 20.9 | 312 / 465 | 165 / 75 | 14.8 / 377 |

| 7P622U160647700 | 6 | 16 | 0.561 / 14.2 | 0.801 / 20.3 | 0.913 / 23.2 | 395 / 587 | 247 / 112 | 16.4 / 417 |

| 7P622U160847700 | 8 | 16 | 0.607 / 15.4 | 0.847 / 21.5 | 0.959 / 24.4 | 457 / 680 | 330 / 150 | 17.3 / 438 |

| 7P622U161247700 | 12 | 16 | 0.756 / 19.2 | 0.996 / 25.3 | 1.108 / 28.1 | 617 / 919 | 494 / 224 | 19.9 / 506 |

| 7P622U162447700 | 24 | 16 | 1.059 / 26.9 | 1.299 / 33.0 | 1.411 / 35.8 | 1029 / 1531 | 989 / 449 | 25.4 / 645 |

| 7P621U180147700 | 1 | 18 | 0.235 / 6.0 | 0.475 / 12.1 | 0.587 / 14.9 | 141 / 210 | 26 / 12 | 10.6 / 268 |

| 7P622U180247700 | 2 | 18 | 0.353 / 9.0 | 0.593 / 15.1 | 0.705 / 17.9 | 210 / 312 | 52 / 24 | 12.7 / 322 |

| 7P622U180447700 | 4 | 18 | 0.428 / 10.9 | 0.668 / 17.0 | 0.780 / 19.8 | 268 / 399 | 104 / 47 | 14 / 357 |

| 7P622U180647700 | 6 | 18 | 0.505 / 12.8 | 0.745 / 18.9 | 0.857 / 21.8 | 331 / 493 | 156 / 71 | 15.4 / 392 |

| 7P622U180847700 | 8 | 18 | 0.546 / 13.9 | 0.786 / 20.0 | 0.898 / 22.8 | 378 / 562 | 208 / 94 | 16.2 / 410 |

| 7P622U181247700 | 12 | 18 | 0.679 / 17.2 | 0.919 / 23.3 | 1.031 / 26.2 | 501 / 745 | 312 / 142 | 18.5 / 471 |

| 7P622U182447700 | 24 | 18 | 0.946 / 24.0 | 1.186 / 30.1 | 1.298 / 33.0 | 813 / 1210 | 624 / 283 | 23.4 / 594 |

Markets / Applications

|

|

Voltage

300 V

Product Construction

-

- Insulation:

- FR PVC rated: 60°C wet / 105°C dry

- XLPE rated (optional)

- VW-1 rated (optional)

- Insulation:

-

- Shielding (foil-free edge):

- ISOS (standard)

- OS (optional)

- Shielding (foil-free edge):

-

- Armor:

- Aluminum Interlocked Armor (AIA) (standard)

- Steel Interlocked Armor (SIA) (optional)

- Served Wire Armor (SWA) (optional)

- Armor:

-

- Jacket:

- FR PVC yellow (standard) dependent on requested thermocouple alloy rated: 90°C to -40°C

- Thermoset CPE (optional)

- Thermoplastic CPE (optional)

- Thermoplastic LSZH (optional)

- Jacket:

- Available in:

- Composite constructions

- Custom insulation / jacket colors

- PLTC/ITC-ER with CPE jackets

- Extension cables for type E, J, K, N, R, S and T thermocouple alloys

Colour Coding

- Type EX: (+) Purple (-) Red Purple jacket

- Type JX: (+) White (-) Red Black jacket

- Type KX: (+) Yellow (-) Red Yellow jacket

- Type NX: (+) Orange (-) Red Orange jacket

- Type RX/SX: (+) Black (-) Red Green jacket

- Type TX: (+) Blue (-) Red Blue jacket

Certifications/Compliances

- UL 13, Power Limited Tray Cable (PLTC)

- UL 2250, Instrumentation Tray Cable (ITC)

- UL 83, Thermoplastic Insulated Wires and Cables

- IEEE 1202 / 383 (70,000 BTU / hr), Vertical Flame Test rated (optional)

- UL 1685 / FT4, Vertical Tray Flame Test rated (optional)

- ICEA T-30-520 (70,000 BTU / hr), Vertical Flame Test rated

- UV sunlight resistant “SUN RES” (all colours)

- -40°C cold bend rated

- Rated for use in hazardous locations:

- Class I Zone 2 (Div 2)

- Class II Zone 22 (Div 2)

- Thermocouple Alloys

- FR PVC insulated Thermocouple Alloy Wires

- Individual Aluminum / Mylar Shielded Pairs with Tin-coated Copper Drain Wire

- Polyester Separator Tape

- Overall Aluminum / Mylar Shield with Tin-coated Copper Drain Wire

- FR PVC Black Inner Protective Jacket

- Aluminum Interlocked Armor (AIA)

- FR PVC Yellow Outer Protective Jacket

| Part Number | Number of Pairs | Conductor Size | OD Over Inner Jacket | Nominal Diameters | Cable Weight | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) | |

| Over Armour | Overall Cable | |||||||

| (AWG/kcmil) | (in/mm) | (in/mm) | (in/mm) | (lbs/1000ft)/(kg/km) | (lb/kg) | (in/mm) | ||

| 7P621U160147700 | 1 | 16 | 0.257 / 6.5 | 0.497 / 12.6 | 0.609 / 15.5 | 155 / 230 | 41 / 19 | 11 / 278 |

| 7P622U160247700 | 2 | 16 | 0.389 / 9.9 | 0.629 / 16 | 0.741 / 18.8 | 238 / 354 | 82 / 37 | 13.3 / 339 |

| 7P622U160447700 | 4 | 16 | 0.472 / 12.0 | 0.712 / 18.1 | 0.824 / 20.9 | 312 / 465 | 165 / 75 | 14.8 / 377 |

| 7P622U160647700 | 6 | 16 | 0.561 / 14.2 | 0.801 / 20.3 | 0.913 / 23.2 | 395 / 587 | 247 / 112 | 16.4 / 417 |

| 7P622U160847700 | 8 | 16 | 0.607 / 15.4 | 0.847 / 21.5 | 0.959 / 24.4 | 457 / 680 | 330 / 150 | 17.3 / 438 |

| 7P622U161247700 | 12 | 16 | 0.756 / 19.2 | 0.996 / 25.3 | 1.108 / 28.1 | 617 / 919 | 494 / 224 | 19.9 / 506 |

| 7P622U162447700 | 24 | 16 | 1.059 / 26.9 | 1.299 / 33.0 | 1.411 / 35.8 | 1029 / 1531 | 989 / 449 | 25.4 / 645 |

| 7P621U180147700 | 1 | 18 | 0.235 / 6.0 | 0.475 / 12.1 | 0.587 / 14.9 | 141 / 210 | 26 / 12 | 10.6 / 268 |

| 7P622U180247700 | 2 | 18 | 0.353 / 9.0 | 0.593 / 15.1 | 0.705 / 17.9 | 210 / 312 | 52 / 24 | 12.7 / 322 |

| 7P622U180447700 | 4 | 18 | 0.428 / 10.9 | 0.668 / 17.0 | 0.780 / 19.8 | 268 / 399 | 104 / 47 | 14 / 357 |

| 7P622U180647700 | 6 | 18 | 0.505 / 12.8 | 0.745 / 18.9 | 0.857 / 21.8 | 331 / 493 | 156 / 71 | 15.4 / 392 |

| 7P622U180847700 | 8 | 18 | 0.546 / 13.9 | 0.786 / 20.0 | 0.898 / 22.8 | 378 / 562 | 208 / 94 | 16.2 / 410 |

| 7P622U181247700 | 12 | 18 | 0.679 / 17.2 | 0.919 / 23.3 | 1.031 / 26.2 | 501 / 745 | 312 / 142 | 18.5 / 471 |

| 7P622U182447700 | 24 | 18 | 0.946 / 24.0 | 1.186 / 30.1 | 1.298 / 33.0 | 813 / 1210 | 624 / 283 | 23.4 / 594 |

|

|