SL-HFA 600/1000 V Armoured Multi-Conductor (LSZH), HF90/SHF1

Construction

Voltage

600/1000v

Operating Temperature

-40°C to +90°C

Product Construction

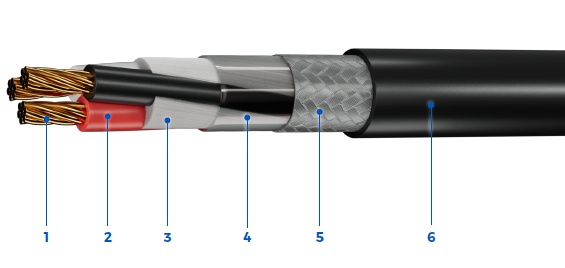

Conductor:

Stranded bare or tinned copper class 5 (standard) or class 2 (optional)

Insulation:

Halogen Free HF90 Rated: +90ºC Wet/Dry, IEC 60092-360

Armour:

Tinned-Copper Braid (Standard)

Bronze Braid (optional)

Jacket:

FR LSZH Thermoplastic, IEC 60092-360 (SHF1)

Available in:

Custom insulation/jacket colours

Certifications

Certification/Compliances

Construction & Materials:

- IEC 60092-353

- IEC 60092-350

- IEC 60092-360 (Insulation & Sheath)

- IEC 60228 (Conductor)

Performance:

- IEC 60332-3-22, Cat. A (Flame Retardancy)

- IEC 60754-1 & 2, IEC 60684-2 (Halogen Free)

- IEC 61034-1 & 2 (Low Smoke Emission)

- IEC 60811-403 (Ozone Resistance)

- Cold Bend & Impact (-40°C/-35°C)

Approvals:

- American Bureau of Shipping (ABS)

- Lloyd’s Register

- Transport Canada

Colour Coding

Custom colour coding available, inc.

• Per IEEE 1580 Table 23:

- 2C – Black, White

- 3C – Black, White, Red

- 4C – Black, White, Red, Green

- 5C – Black, White, Red, Green, Orange

- 6C – Black, White, Red, Green, Orange, Blue

- ≥7C – Base color with tracers

Properties

- Stranded Bare or Tinned Class 2 or Class 5 Copper Conductors

- Halogen Free HF90 Insulated Conductors

- Polypropylene Fillers

- Fiberglass Tape

Optional: LSZH Inner Sheath (Not Shown) - Tinned-Copper or Bronze Braided Armour

- Protective LSZH Outer Sheath

| NUMBER OF CONDUCTORS |

x | SIZE OF CONDUCTORS |

NOMINAL OD OVERALL CABLE |

CABLE WEIGHT | AMPACITY | SHAWFLEX PART NUMBER |

| (c) | (mm2) | (in/mm) | (lbs/1000ft) / (kg/km) | (45°C ambient) | ||

| 2c | x | 1 | 0.4 / 9.3 | 106.12 / 157.92 | 16 | SLC11E0102F0800 |

| 2c | x | 1.5 | 0.4 / 10.2 | 123.99 / 184.51 | 20 | SLC11E3A02F0800 |

| 2c | x | 2.5 | 0.5 / 11.5 | 168.8 / 251.2 | 26 | SLC11E5A02F0800 |

| 2c | x | 4 | 0.5 / 12.5 | 202.7 / 301.66 | 34 | SLC11E0402F0800 |

| 2c | x | 6 | 0.6 / 14.3 | 257.76 / 383.59 | 44 | SLC11E0602F0800 |

| 2c | x | 10 | 0.6 / 15.8 | 332.91 / 495.42 | 61 | SLC11E1002F0800 |

| 2c | x | 16 | 0.8 / 19.3 | 479.6 / 713.72 | 82 | SLC11E1602F0800 |

| 2c | x | 25 | 0.9 / 22.9 | 672.78 / 1001.2 | 108 | SLC11E2502F0800 |

| 2c | x | 35 | 1 / 25.7 | 850.04 / 1265 | 133 | SLC11E3502F0800 |

| 2c | x | 50 | 1.1 / 28.7 | 1121.9 / 1669.56 | 167 | SLC11E5002F0800 |

| Type | X | Size | Weight (kg/m) | Pulling Force (N) | Bending Radius (mm) | Part Number |

|---|---|---|---|---|---|---|

| 3c | x | 1 | 0.4 / 9.7 | 117.85 / 175.38 | 12 | SLC11E0103F0800 |

| 3c | x | 1.5 | 0.4 / 10.7 | 139.86 / 208.14 | 16 | SLC11E3A03F0800 |

| 3c | x | 2.5 | 0.5 / 12 | 192.08 / 285.84 | 21 | SLC11E5A03F0800 |

| 3c | x | 4 | 0.5 / 13.4 | 245.47 / 365.3 | 28 | SLC11E0403F0800 |

| 3c | x | 6 | 0.6 / 15.1 | 307.67 / 457.87 | 36 | SLC11E0603F0800 |

| 3c | x | 10 | 0.7 / 16.9 | 415.9 / 618.93 | 50 | SLC11E1003F0800 |

| 3c | x | 16 | 0.8 / 20.6 | 611.16 / 909.51 | 67 | SLC11E1603F0800 |

| 3c | x | 25 | 1 / 24.4 | 863.89 / 1285.6 | 89 | SLC11E2503F0800 |

| 3c | x | 35 | 1.1 / 27.4 | 1110.01 / 1651.87 | 110 | SLC11E3503F0800 |

| 3c | x | 50 | 1.2 / 30.7 | 1473.14 / 2192.27 | 137 | SLC11E5003F0800 |

| 4c | x | 1 | 0.4 / 10.4 | 131.73 / 196.03 | 12 | SLC11E0104F0800 |

| 4c | x | 1.5 | 0.5 / 11.9 | 179.94 / 267.78 | 16 | SLC11E3A04F0800 |

| 4c | x | 2.5 | 0.5 / 13.2 | 230.61 / 343.18 | 21 | SLC11E5A04F0800 |

| 4c | x | 4 | 0.6 / 14.4 | 285.69 / 425.15 | 28 | SLC11E0404F0800 |

| 4c | x | 6 | 0.7 / 16.5 | 375.97 / 559.51 | 36 | SLC11E0604F0800 |

| 4c | x | 10 | 0.7 / 18.3 | 502.33 / 747.55 | 50 | SLC11E1004F0800 |

| 4c | x | 16 | 0.8 / 22.5 | 745.45 / 1109.35 | 67 | SLC11E1604F0800 |

| 4c | x | 25 | 1.1 / 27 | 1084.46 / 1613.86 | 89 | SLC11E2504F0800 |

| Type | X | Size | Weight (kg/m) | Pulling Force (N) | Bending Radius (mm) | Part Number |

| 5c | x | 1 | 0.5 / 11.9 | 176.27 / 262.32 | 9.6 | SLC11E0105F0800 |

| 5c | x | 1.5 | 0.5 / 13 | 211.55 / 314.82 | 12.8 | SLC11E3A05F0800 |

| 5c | x | 2.5 | 0.6 / 14.2 | 265.07 / 394.47 | 16.8 | SLC11E5A05F0800 |

| 5c | x | 4 | 0.6 / 15.6 | 332.2 / 494.37 | 22.4 | SLC11E0405F0800 |

| 5c | x | 6 | 0.7 / 17.9 | 434.39 / 646.44 | 28.8 | SLC11E0605F0800 |

| 5c | x | 10 | 0.8 / 20.2 | 605.19 / 900.62 | 40 | SLC11E1005F0800 |

| 5c | x | 16 | 1 / 24.7 | 904.86 / 1346.58 | 53.6 | SLC11E1605F0800 |

| 5c | x | 25 | 1.2 / 29.4 | 1304.14 / 1940.78 | 71.2 | SLC11E2505F0800 |

| 7c | x | 1 | 0.5 / 13 | 210.31 / 312.97 | 8.4 | SLC11E0107F0800 |

| 7c | x | 1.5 | 0.5 / 13.9 | 246.37 / 366.64 | 11.2 | SLC11E3A07F0800 |

| 7c | x | 2.5 | 0.6 / 15.2 | 309.47 / 460.54 | 14.7 | SLC11E5A07F0800 |

| 10c | x | 1 | 0.6 / 15.7 | 275.9 / 410.58 | 8.4 | SLC11E0110F0800 |

| 10c | x | 1.5 | 0.7 / 17.2 | 336.87 / 501.31 | 11.2 | SLC11E3A10F0800 |

| 10c | x | 2.5 | 0.7 / 18.9 | 426.03 / 634 | 14.7 | SLC11E5A10F0800 |

| 12c | x | 1 | 0.6 / 16.1 | 297.59 / 442.87 | 8.4 | SLC11E0112F0800 |

| 12c | x | 1.5 | 0.7 / 17.7 | 366.41 / 545.28 | 11.2 | SLC11E3A12F0800 |

| 12c | x | 2.5 | 0.8 / 19.5 | 468.59 / 697.34 | 14.7 | SLC11E5A12F0800 |

| 14c | x | 1 | 0.7 / 17.1 | 331.1 / 492.72 | 8.4 | SLC11E0114F0800 |

| 14c | x | 1.5 | 0.7 / 18.5 | 398.38 / 592.85 | 11.2 | SLC11E3A14F0800 |

| 14c | x | 2.5 | 0.8 / 20.6 | 531.16 / 790.45 | 14.7 | SLC11E5A14F0800 |

| 19c | x | 1 | 0.7 / 18.7 | 396.51 / 590.07 | 8.4 | SLC11E0119F0800 |

| 19c | x | 1.5 | 0.8 / 20.5 | 495.55 / 737.47 | 11.2 | SLC11E3A19F0800 |

| 19c | x | 2.5 | 0.9 / 22.7 | 649.26 / 966.21 | 14.7 | SLC11E5A19F0800 |

| 24c | x | 1 | 0.9 / 21.7 | 498.8 / 742.29 | 8.4 | SLC11E0124F0800 |

| 24c | x | 1.5 | 0.9 / 23.8 | 624.34 / 929.12 | 11.2 | SLC11E3A24F0800 |

| 24c | x | 2.5 | 1 / 26.4 | 821.64 / 1222.73 | 14.7 | SLC11E5A24F0800 |

| 27c | x | 1 | 0.9 / 22.1 | 530.12 / 788.91 | 7.2 | SLC11E0127F0800 |

| 27c | x | 1.5 | 1 / 24.3 | 667.28 / 993.01 | 9.6 | SLC11E3A27F0800 |

| 27c | x | 2.5 | 1.1 / 27.2 | 899.87 / 1339.16 | 12.6 | SLC11E5A27F0800 |

| 37c | x | 1 | 1 / 24.7 | 662.85 / 986.42 | 7.2 | SLC11E0137F0800 |

| 37c | x | 1.5 | 1.1 / 27.1 | 841.6 / 1252.43 | 9.6 | SLC11E3A37F0800 |

| 37c | x | 2.5 | 1.2 / 30.4 | 1149.02 / 1709.93 | 12.6 | SLC11E5A37F0800 |

*Ampacity value based on ABS Rules for Building and Classing Steel Vessels, Version 2023, Table-6. Values are corrected according to Table 6 for number of Conductors.

**Available in both American Wire Gauge (AWG) and Metric wire conductor sizes.

Markets / Applications

Marine & Shipboard

Voltage

600/1000v

Operating Temperature

-40°C to +90°C

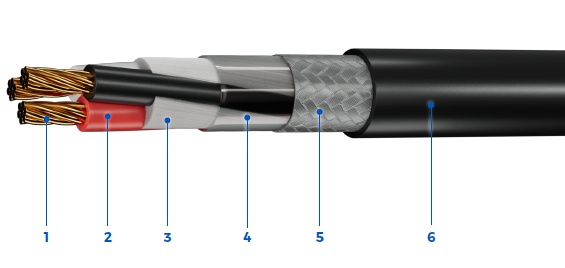

Product Construction

Conductor:

Stranded bare or tinned copper class 5 (standard) or class 2 (optional)

Insulation:

Halogen Free HF90 Rated: +90ºC Wet/Dry, IEC 60092-360

Armour:

Tinned-Copper Braid (Standard)

Bronze Braid (optional)

Jacket:

FR LSZH Thermoplastic, IEC 60092-360 (SHF1)

Available in:

Custom insulation/jacket colours

Certification/Compliances

Construction & Materials:

- IEC 60092-353

- IEC 60092-350

- IEC 60092-360 (Insulation & Sheath)

- IEC 60228 (Conductor)

Performance:

- IEC 60332-3-22, Cat. A (Flame Retardancy)

- IEC 60754-1 & 2, IEC 60684-2 (Halogen Free)

- IEC 61034-1 & 2 (Low Smoke Emission)

- IEC 60811-403 (Ozone Resistance)

- Cold Bend & Impact (-40°C/-35°C)

Approvals:

- American Bureau of Shipping (ABS)

- Lloyd’s Register

- Transport Canada

Colour Coding

Custom colour coding available, inc.

• Per IEEE 1580 Table 23:

- 2C – Black, White

- 3C – Black, White, Red

- 4C – Black, White, Red, Green

- 5C – Black, White, Red, Green, Orange

- 6C – Black, White, Red, Green, Orange, Blue

- ≥7C – Base color with tracers

- Stranded Bare or Tinned Class 2 or Class 5 Copper Conductors

- Halogen Free HF90 Insulated Conductors

- Polypropylene Fillers

- Fiberglass Tape

Optional: LSZH Inner Sheath (Not Shown) - Tinned-Copper or Bronze Braided Armour

- Protective LSZH Outer Sheath

| NUMBER OF CONDUCTORS |

x | SIZE OF CONDUCTORS |

NOMINAL OD OVERALL CABLE |

CABLE WEIGHT | AMPACITY | SHAWFLEX PART NUMBER |

| (c) | (mm2) | (in/mm) | (lbs/1000ft) / (kg/km) | (45°C ambient) | ||

| 2c | x | 1 | 0.4 / 9.3 | 106.12 / 157.92 | 16 | SLC11E0102F0800 |

| 2c | x | 1.5 | 0.4 / 10.2 | 123.99 / 184.51 | 20 | SLC11E3A02F0800 |

| 2c | x | 2.5 | 0.5 / 11.5 | 168.8 / 251.2 | 26 | SLC11E5A02F0800 |

| 2c | x | 4 | 0.5 / 12.5 | 202.7 / 301.66 | 34 | SLC11E0402F0800 |

| 2c | x | 6 | 0.6 / 14.3 | 257.76 / 383.59 | 44 | SLC11E0602F0800 |

| 2c | x | 10 | 0.6 / 15.8 | 332.91 / 495.42 | 61 | SLC11E1002F0800 |

| 2c | x | 16 | 0.8 / 19.3 | 479.6 / 713.72 | 82 | SLC11E1602F0800 |

| 2c | x | 25 | 0.9 / 22.9 | 672.78 / 1001.2 | 108 | SLC11E2502F0800 |

| 2c | x | 35 | 1 / 25.7 | 850.04 / 1265 | 133 | SLC11E3502F0800 |

| 2c | x | 50 | 1.1 / 28.7 | 1121.9 / 1669.56 | 167 | SLC11E5002F0800 |

| Type | X | Size | Weight (kg/m) | Pulling Force (N) | Bending Radius (mm) | Part Number |

|---|---|---|---|---|---|---|

| 3c | x | 1 | 0.4 / 9.7 | 117.85 / 175.38 | 12 | SLC11E0103F0800 |

| 3c | x | 1.5 | 0.4 / 10.7 | 139.86 / 208.14 | 16 | SLC11E3A03F0800 |

| 3c | x | 2.5 | 0.5 / 12 | 192.08 / 285.84 | 21 | SLC11E5A03F0800 |

| 3c | x | 4 | 0.5 / 13.4 | 245.47 / 365.3 | 28 | SLC11E0403F0800 |

| 3c | x | 6 | 0.6 / 15.1 | 307.67 / 457.87 | 36 | SLC11E0603F0800 |

| 3c | x | 10 | 0.7 / 16.9 | 415.9 / 618.93 | 50 | SLC11E1003F0800 |

| 3c | x | 16 | 0.8 / 20.6 | 611.16 / 909.51 | 67 | SLC11E1603F0800 |

| 3c | x | 25 | 1 / 24.4 | 863.89 / 1285.6 | 89 | SLC11E2503F0800 |

| 3c | x | 35 | 1.1 / 27.4 | 1110.01 / 1651.87 | 110 | SLC11E3503F0800 |

| 3c | x | 50 | 1.2 / 30.7 | 1473.14 / 2192.27 | 137 | SLC11E5003F0800 |

| 4c | x | 1 | 0.4 / 10.4 | 131.73 / 196.03 | 12 | SLC11E0104F0800 |

| 4c | x | 1.5 | 0.5 / 11.9 | 179.94 / 267.78 | 16 | SLC11E3A04F0800 |

| 4c | x | 2.5 | 0.5 / 13.2 | 230.61 / 343.18 | 21 | SLC11E5A04F0800 |

| 4c | x | 4 | 0.6 / 14.4 | 285.69 / 425.15 | 28 | SLC11E0404F0800 |

| 4c | x | 6 | 0.7 / 16.5 | 375.97 / 559.51 | 36 | SLC11E0604F0800 |

| 4c | x | 10 | 0.7 / 18.3 | 502.33 / 747.55 | 50 | SLC11E1004F0800 |

| 4c | x | 16 | 0.8 / 22.5 | 745.45 / 1109.35 | 67 | SLC11E1604F0800 |

| 4c | x | 25 | 1.1 / 27 | 1084.46 / 1613.86 | 89 | SLC11E2504F0800 |

| Type | X | Size | Weight (kg/m) | Pulling Force (N) | Bending Radius (mm) | Part Number |

| 5c | x | 1 | 0.5 / 11.9 | 176.27 / 262.32 | 9.6 | SLC11E0105F0800 |

| 5c | x | 1.5 | 0.5 / 13 | 211.55 / 314.82 | 12.8 | SLC11E3A05F0800 |

| 5c | x | 2.5 | 0.6 / 14.2 | 265.07 / 394.47 | 16.8 | SLC11E5A05F0800 |

| 5c | x | 4 | 0.6 / 15.6 | 332.2 / 494.37 | 22.4 | SLC11E0405F0800 |

| 5c | x | 6 | 0.7 / 17.9 | 434.39 / 646.44 | 28.8 | SLC11E0605F0800 |

| 5c | x | 10 | 0.8 / 20.2 | 605.19 / 900.62 | 40 | SLC11E1005F0800 |

| 5c | x | 16 | 1 / 24.7 | 904.86 / 1346.58 | 53.6 | SLC11E1605F0800 |

| 5c | x | 25 | 1.2 / 29.4 | 1304.14 / 1940.78 | 71.2 | SLC11E2505F0800 |

| 7c | x | 1 | 0.5 / 13 | 210.31 / 312.97 | 8.4 | SLC11E0107F0800 |

| 7c | x | 1.5 | 0.5 / 13.9 | 246.37 / 366.64 | 11.2 | SLC11E3A07F0800 |

| 7c | x | 2.5 | 0.6 / 15.2 | 309.47 / 460.54 | 14.7 | SLC11E5A07F0800 |

| 10c | x | 1 | 0.6 / 15.7 | 275.9 / 410.58 | 8.4 | SLC11E0110F0800 |

| 10c | x | 1.5 | 0.7 / 17.2 | 336.87 / 501.31 | 11.2 | SLC11E3A10F0800 |

| 10c | x | 2.5 | 0.7 / 18.9 | 426.03 / 634 | 14.7 | SLC11E5A10F0800 |

| 12c | x | 1 | 0.6 / 16.1 | 297.59 / 442.87 | 8.4 | SLC11E0112F0800 |

| 12c | x | 1.5 | 0.7 / 17.7 | 366.41 / 545.28 | 11.2 | SLC11E3A12F0800 |

| 12c | x | 2.5 | 0.8 / 19.5 | 468.59 / 697.34 | 14.7 | SLC11E5A12F0800 |

| 14c | x | 1 | 0.7 / 17.1 | 331.1 / 492.72 | 8.4 | SLC11E0114F0800 |

| 14c | x | 1.5 | 0.7 / 18.5 | 398.38 / 592.85 | 11.2 | SLC11E3A14F0800 |

| 14c | x | 2.5 | 0.8 / 20.6 | 531.16 / 790.45 | 14.7 | SLC11E5A14F0800 |

| 19c | x | 1 | 0.7 / 18.7 | 396.51 / 590.07 | 8.4 | SLC11E0119F0800 |

| 19c | x | 1.5 | 0.8 / 20.5 | 495.55 / 737.47 | 11.2 | SLC11E3A19F0800 |

| 19c | x | 2.5 | 0.9 / 22.7 | 649.26 / 966.21 | 14.7 | SLC11E5A19F0800 |

| 24c | x | 1 | 0.9 / 21.7 | 498.8 / 742.29 | 8.4 | SLC11E0124F0800 |

| 24c | x | 1.5 | 0.9 / 23.8 | 624.34 / 929.12 | 11.2 | SLC11E3A24F0800 |

| 24c | x | 2.5 | 1 / 26.4 | 821.64 / 1222.73 | 14.7 | SLC11E5A24F0800 |

| 27c | x | 1 | 0.9 / 22.1 | 530.12 / 788.91 | 7.2 | SLC11E0127F0800 |

| 27c | x | 1.5 | 1 / 24.3 | 667.28 / 993.01 | 9.6 | SLC11E3A27F0800 |

| 27c | x | 2.5 | 1.1 / 27.2 | 899.87 / 1339.16 | 12.6 | SLC11E5A27F0800 |

| 37c | x | 1 | 1 / 24.7 | 662.85 / 986.42 | 7.2 | SLC11E0137F0800 |

| 37c | x | 1.5 | 1.1 / 27.1 | 841.6 / 1252.43 | 9.6 | SLC11E3A37F0800 |

| 37c | x | 2.5 | 1.2 / 30.4 | 1149.02 / 1709.93 | 12.6 | SLC11E5A37F0800 |

*Ampacity value based on ABS Rules for Building and Classing Steel Vessels, Version 2023, Table-6. Values are corrected according to Table 6 for number of Conductors.

**Available in both American Wire Gauge (AWG) and Metric wire conductor sizes.

Marine & Shipboard