CSA TYPE RW90 CIC TC Tray VFD, Multi-Conductor, 1000 V

Shawflex VFD cables are the preferred power cables for AC Drives. These cables are primarily used between Pulse Width Modulation (PWM) inverters and AC motors. ShawFlex VFD Tray cables are suitable for use in raceways, including ventilated, non-ventilated, indoor/outdoor and ladder-type cable trays in wet/dry locations and are applicable in Industrial and Processing facilities.

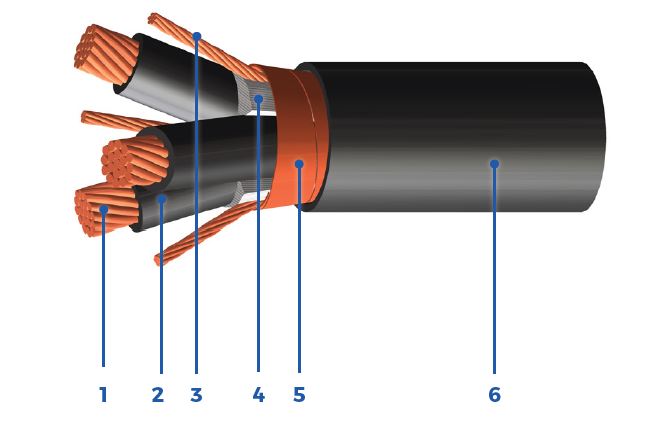

Construction

Voltage

1000 V

Optional: 600 / 2000 V

Product Construction

Insulation:

XLPE (RW90 rated)rated: 90°C wet / 105°C dry

Shielding:

Helically applied copper tape shield

Jacket:

FR PVC outer black or yellow jacket (standard) rated: 90°C to -40°C

Available in:

Custom insulation/jacket colours

LSZH Jacket

Certifications

Certifications/Compliances

- CSA C22.2 No. 230, Tray cables

- CSA C22.2 No. 239, Control and instrumentation cables

- CSA C22.2 No. 38, Thermoset-insulated wires and cables

- CSA C22.2 No. 2556/UL 2556 FT4, Vertical Tray Flame Test rated

- IEEE 383/1202 (70,000 BTU/hr), Vertical Flame Test rated

- UV sunlight resistant “SUN RES” (all colours)

- Direct burial rated

- – 40°C cold bend/impact rated

- Rated for use in hazardous locations:

- Zone 0 (Class 1, Division 1) (Intrinsically Safe circuits only)

- Zone 2 (Class I, Division 2)

- Zone 22 (Class II & III, Division 2)

Colour Coding

- 3C Black, # coded

Properties

- Stranded Bare (ASTM B8) Annealed Copper Conductors

- XLPE (RW90 Rated) Insulated Conductors

- Tri-sectional Grounding Conductors

- Polypropylene Fillers

- Helically Applied Bare / Tinned Copper Tape Shield

- FR PVC Outer Protective Jacket

| Part Number | Number of Conductors | Conductor Size | Ground Wire Size | Nominal Diameter Overall cable | Cable Weight | Ampacity | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) |

| AWG or kcmil | AWG | in. | mm | lb|1000ft | kg|km |

30°C ambient | lb | kg | in. | mm | ||

| 4D01HM1203000DR | 3 | 12 | 3 x 18 | 0.503 | 12.8 | 178 | 266 | 30 | 157 | 71 | 9.1 | 230 |

| 4D01HM1003000DR | 3 | 10 | 3 x 16 | 0.595 | 15.1 | 276 | 410 | 40 | 249 | 113 | 10.7 | 272 |

| 4D01HM0803000DR | 3 | 8 | 3 x 14 | 0.657 | 16.7 | 377 | 561 | 55 | 397 | 180 | 11.8 | 300 |

| 4D013M0603000DR | 3 | 6 | 3 x 12 | 0.801 | 20.4 | 561 | 834 | 75 | 629 | 285 | 14.4 | 366 |

| 4D013M0403000DR | 3 | 4 | 3 x 12 | 0.942 | 24.0 | 788 | 1173 | 95 | 1002 | 454 | 17.0 | 431 |

| 4D013M0203000DR | 3 | 2 | 3 x 10 | 1.067 | 27.1 | 1111 | 1653 | 130 | 1593 | 723 | 19.2 | 488 |

| 4D013M0103400DR | 3 | 1 | 3 x 10 | 1.237 | 31.4 | 1394 | 2075 | 145 | 2009 | 911 | 22.3 | 566 |

| 4D013M1/03400DR | 3 | 1/0 | 3 x 10 | 1.323 | 33.6 | 1643 | 2446 | 170 | 2534 | 1150 | 23.8 | 605 |

| 4D013M2/03400DR | 3 | 2/0 | 3 x 10 | 1.415 | 36.0 | 1965 | 2925 | 195 | 3194 | 1449 | 25.5 | 647 |

| 4D013M3/03400DR | 3 | 3/0 | 3 x 8 | 1.525 | 38.7 | 2409 | 3584 | 225 | 4007 | 1818 | 27.5 | 697 |

| 4D013M4/03400DR | 3 | 4/0 | 3 x 8 | 1.645 | 41.8 | 2896 | 4310 | 260 | 5078 | 2304 | 29.6 | 752 |

| 4D013M2503600DR | 3 | 250 | 3 x 8 | 1.847 | 46.9 | 3379 | 5028 | 290 | 6000 | 2722 | 33.3 | 845 |

| 4D013M3503600DR | 3 | 350 | 3 x 6 | 2.069 | 52.6 | 4669 | 6949 | 350 | 8400 | 3810 | 37.2 | 946 |

| 4D013M5003600DR | 3 | 500 | 3 x 6 | 2.344 | 59.5 | 6305 | 9383 | 430 | 12000 | 5443 | 42.2 | 1072 |

| 4D013M7503600DR | 3 | 750 | 3 x 6 | 2.729 | 69.3 | 8638 | 12855 | 535 | 18000 | 8165 | 49.1 | 1248 |

*Ampacity value based on Canadian Electrical Code, Part 1 (2021 25th Edition), Table 2. Values are corrected for number of insulated conductors as applicable according to Table 5C.

Markets / Applications

- Water/Waste Water Treatment

- Industrial Construction/Automation

- Industrial

- Petrochem/Pulp & Paper

- Energy

Voltage

1000 V

Optional: 600 / 2000 V

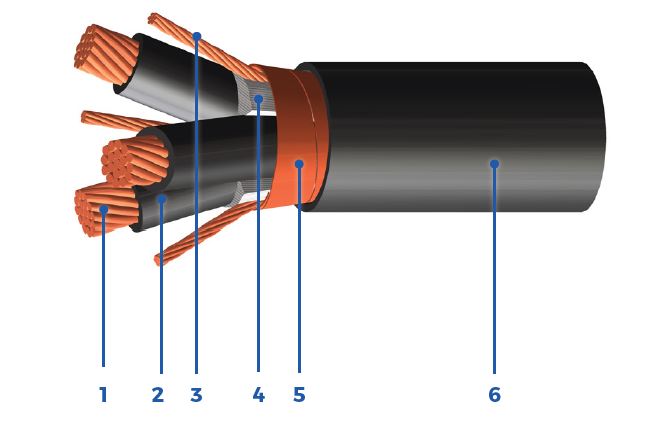

Product Construction

Insulation:

XLPE (RW90 rated)rated: 90°C wet / 105°C dry

Shielding:

Helically applied copper tape shield

Jacket:

FR PVC outer black or yellow jacket (standard) rated: 90°C to -40°C

Available in:

Custom insulation/jacket colours

LSZH Jacket

Certifications/Compliances

- CSA C22.2 No. 230, Tray cables

- CSA C22.2 No. 239, Control and instrumentation cables

- CSA C22.2 No. 38, Thermoset-insulated wires and cables

- CSA C22.2 No. 2556/UL 2556 FT4, Vertical Tray Flame Test rated

- IEEE 383/1202 (70,000 BTU/hr), Vertical Flame Test rated

- UV sunlight resistant “SUN RES” (all colours)

- Direct burial rated

- – 40°C cold bend/impact rated

- Rated for use in hazardous locations:

- Zone 0 (Class 1, Division 1) (Intrinsically Safe circuits only)

- Zone 2 (Class I, Division 2)

- Zone 22 (Class II & III, Division 2)

Colour Coding

- 3C Black, # coded

- Stranded Bare (ASTM B8) Annealed Copper Conductors

- XLPE (RW90 Rated) Insulated Conductors

- Tri-sectional Grounding Conductors

- Polypropylene Fillers

- Helically Applied Bare / Tinned Copper Tape Shield

- FR PVC Outer Protective Jacket

| Part Number | Number of Conductors | Conductor Size | Ground Wire Size | Nominal Diameter Overall cable | Cable Weight | Ampacity | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) |

| AWG or kcmil | AWG | in. | mm | lb|1000ft | kg|km |

30°C ambient | lb | kg | in. | mm | ||

| 4D01HM1203000DR | 3 | 12 | 3 x 18 | 0.503 | 12.8 | 178 | 266 | 30 | 157 | 71 | 9.1 | 230 |

| 4D01HM1003000DR | 3 | 10 | 3 x 16 | 0.595 | 15.1 | 276 | 410 | 40 | 249 | 113 | 10.7 | 272 |

| 4D01HM0803000DR | 3 | 8 | 3 x 14 | 0.657 | 16.7 | 377 | 561 | 55 | 397 | 180 | 11.8 | 300 |

| 4D013M0603000DR | 3 | 6 | 3 x 12 | 0.801 | 20.4 | 561 | 834 | 75 | 629 | 285 | 14.4 | 366 |

| 4D013M0403000DR | 3 | 4 | 3 x 12 | 0.942 | 24.0 | 788 | 1173 | 95 | 1002 | 454 | 17.0 | 431 |

| 4D013M0203000DR | 3 | 2 | 3 x 10 | 1.067 | 27.1 | 1111 | 1653 | 130 | 1593 | 723 | 19.2 | 488 |

| 4D013M0103400DR | 3 | 1 | 3 x 10 | 1.237 | 31.4 | 1394 | 2075 | 145 | 2009 | 911 | 22.3 | 566 |

| 4D013M1/03400DR | 3 | 1/0 | 3 x 10 | 1.323 | 33.6 | 1643 | 2446 | 170 | 2534 | 1150 | 23.8 | 605 |

| 4D013M2/03400DR | 3 | 2/0 | 3 x 10 | 1.415 | 36.0 | 1965 | 2925 | 195 | 3194 | 1449 | 25.5 | 647 |

| 4D013M3/03400DR | 3 | 3/0 | 3 x 8 | 1.525 | 38.7 | 2409 | 3584 | 225 | 4007 | 1818 | 27.5 | 697 |

| 4D013M4/03400DR | 3 | 4/0 | 3 x 8 | 1.645 | 41.8 | 2896 | 4310 | 260 | 5078 | 2304 | 29.6 | 752 |

| 4D013M2503600DR | 3 | 250 | 3 x 8 | 1.847 | 46.9 | 3379 | 5028 | 290 | 6000 | 2722 | 33.3 | 845 |

| 4D013M3503600DR | 3 | 350 | 3 x 6 | 2.069 | 52.6 | 4669 | 6949 | 350 | 8400 | 3810 | 37.2 | 946 |

| 4D013M5003600DR | 3 | 500 | 3 x 6 | 2.344 | 59.5 | 6305 | 9383 | 430 | 12000 | 5443 | 42.2 | 1072 |

| 4D013M7503600DR | 3 | 750 | 3 x 6 | 2.729 | 69.3 | 8638 | 12855 | 535 | 18000 | 8165 | 49.1 | 1248 |

*Ampacity value based on Canadian Electrical Code, Part 1 (2021 25th Edition), Table 2. Values are corrected for number of insulated conductors as applicable according to Table 5C.

- Water/Waste Water Treatment

- Industrial Construction/Automation

- Industrial

- Petrochem/Pulp & Paper

- Energy