UL Armoured VFD Metal Clad AIA | Multi-Conductor (600/1000V)

Construction

Voltage

600V

Optional: 1000V

Product Construction

- Insulation:

- FR XLPE (XHHW-2 rated)rated: 90°C wet / dry Shielding:

- Dual helically applied copper tape shield

- Shielding:

- Dual helically applied copper tape shield

- Armour:

- Aluminum Interlocking Armor (AIA) (standard)

- Steel Interlocking Armor (SIA) (optional)

- Jacket:

- FRPVC outer black or yellow jacket (standard) rated: 90°C to -40°C

- Thermoset CPE optional)

- Thermoplastic CPE (optional)

- Thermoplastic LSZH (optional)

- Available in:

- Custom insulation / jacket colours

- TC-ER (optional)

Certifications

Certifications/Compliances

- UL 1569, Metal Clad Cables (MC)

- UL 44, Thermoset Insulated Wires and Cables

- UL 1685 / FT4, Vertical Tray Flame Test rated

- IEEE 1202 / 383 (70,000 BTU / hr), Vertical Flame Test rated

- ICEA T-30-520 (70,000 BTU / hr), Vertical Flame Test rated

- XLPE (XHHW-2 rated), 90°C wet / dry

- UV sunlight resistant SUN RES (all colours)

- (Direct burial rated)

- -40°C cold bend rated

- Rated for use in hazardous locations:

- Class I Zone 2 (Div 2)

- Class II Zone 20, 21 (Div 1)

- Class II Zone 22 (Div 2)

Colour Coding

- 3C Black, # coded

- Method 4 (optional)

Properties

![]()

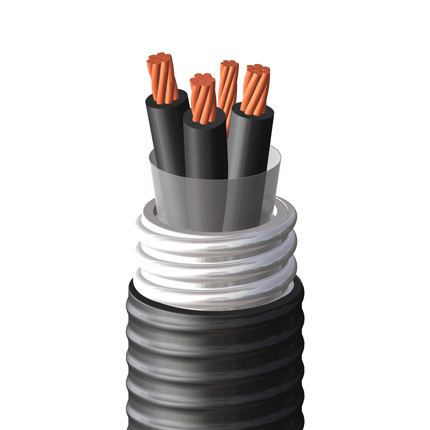

- Tri-sectional Grounding Conductors

- Stranded Bare (ASTM B8) Annealed Copper Conductors

- FR XLPE (XHHW-2 Rated) Insulated Conductors

- Polypropylene Fillers

- Polyester Separator Tape

- Dual Helically Applied Bare / Tinned Copper Tape Shield

- FR PVC Inner Protective Jacket

- Aluminum Interlocked Armor (AIA) (standard)

- FR PVC Outer Protective Jacket

| Part Number | Number of Conductors | Conductor Size (AWG/MCM) | Ground Wire Size (uninsulated) (AWG/MCM) | OD Over Inner Jacket (in/mm) | Nominal Diameters | Cable Weight (lbs/1000ft)/ (kg/km) | Ampacity (30°Cambient) | Max. Pulling Tension (Pulling Eye) (lb/kg) | Min. Bend Radius (Pull) (in/mm) | |

| Over Armour (in/mm) | Overall Cable (in/mm) | |||||||||

| 2C61HU1203007DR | 3 | 12 | 16 | 0.439 / 11.14 | 0.678 / 17.23 | 0.798 / 20.28 | 386 / 574 | 30 | 157 / 71 | 14.4 / 365 |

| 2C61HU1003007DR | 3 | 10 | 14 | 0.5 / 12.71 | 0.74 / 18.81 | 0.9 / 22.87 | 538 / 800 | 40 | 249 / 113 | 16.2 / 412 |

| 2C61HU0803007DR | 3 | 8 | 14 | 0.657 / 16.69 | 0.897 / 22.79 | 1.057 / 26.86 | 769 / 1144 | 55 | 397 / 180 | 19 / 483 |

| 2C613U0603007DR | 3 | 6 | 12 | 0.737 / 18.71 | 0.977 / 24.81 | 1.137 / 28.87 | 982 / 1462 | 75 | 629 / 285 | 20.5 / 520 |

| 2C613U0403007DR | 3 | 4 | 12 | 0.838 / 21.28 | 1.042 / 26.46 | 1.202 / 30.52 | 1256 / 1870 | 95 | 1002 / 454 | 21.6 / 549 |

| 2C613U0203007DR | 3 | 2 | 10 | 1.003 / 25.46 | 1.207 / 30.65 | 1.367 / 34.71 | 1755 / 2612 | 130 | 1593 / 723 | 24.6 / 625 |

| 2C613U0103407DR | 3 | 1 | 10 | 1.129 / 28.69 | 1.334 / 33.87 | 1.493 / 37.93 | 2125 / 3163 | 145 | 2009 / 911 | 26.9 / 683 |

| 2C613U1/03407DR | 3 | 1/0 | 10 | 1.215 / 30.87 | 1.42 / 36.06 | 1.579 / 40.12 | 2498 / 3717 | 170 | 2534 / 1150 | 28.4 / 722 |

| 2C613U2/03407DR | 3 | 2/0 | 10 | 1.308 / 33.22 | 1.512 / 38.4 | 1.672 / 42.46 | 2922 / 4348 | 195 | 3194 / 1449 | 30.1 / 764 |

| 2C613U3/03407DR | 3 | 3/0 | 8 | 1.417 / 36 | 1.622 / 41.19 | 1.842 / 46.78 | 3621 / 5389 | 225 | 4007 / 1818 | 33.1 / 842 |

| 2C613U4/03407DR | 3 | 4/0 | 8 | 1.538 / 39.06 | 1.742 / 44.24 | 1.962 / 49.83 | 4296 / 6393 | 260 | 5078 / 2304 | 35.3 / 897 |

| 2C613U2503607DR | 3 | 250 | 8 | 1.68 / 42.67 | 1.985 / 50.41 | 2.205 / 56 | 5194 / 7730 | 290 | 6000 / 2722 | 39.7 / 1008 |

| 2C613U3503607DR | 3 | 350 | 6 | 1.961 / 49.82 | 2.266 / 57.57 | 2.486 / 63.16 | 6960 / 10358 | 350 | 8400 / 3810 | 44.8 / 1137 |

| 2C613U5003607DR | 3 | 500 | 6 | 2.236 / 56.81 | 2.542 / 64.55 | 2.822 / 71.67 | 9325 / 13877 | 430 | 12000 / 5443 | 50.8 / 1290 |

| 2C613U7503607DR | 3 | 750 | 4 | 2.686 / 68.22 | 2.991 / 75.96 | 3.271 / 83.08 | 13110 / 19509 | 535 | 18000 / 8165 | 58.9 / 1495 |

*Ampacity value based on National Electrical Code, Version 2020, Table 310.16. Values are corrected according to Table 310.15(C)(1) for number of Conductors.

Markets / Applications

- Transit

- Water/Waste Water Treatment

- Generation

- Communication Power & Control

- Generation – Nuclear

- Power Distribution

- Industrial Construction/Automation

- Civil Construction Projects

- Industrial

- Generation – Renewables

- Petrochem/Pulp & Paper

- Utility

- Commercial Construction Projects

- OIl & Gas

- Mining

Voltage

600V

Optional: 1000V

Product Construction

- Insulation:

- FR XLPE (XHHW-2 rated)rated: 90°C wet / dry Shielding:

- Dual helically applied copper tape shield

- Shielding:

- Dual helically applied copper tape shield

- Armour:

- Aluminum Interlocking Armor (AIA) (standard)

- Steel Interlocking Armor (SIA) (optional)

- Jacket:

- FRPVC outer black or yellow jacket (standard) rated: 90°C to -40°C

- Thermoset CPE optional)

- Thermoplastic CPE (optional)

- Thermoplastic LSZH (optional)

- Available in:

- Custom insulation / jacket colours

- TC-ER (optional)

Certifications/Compliances

- UL 1569, Metal Clad Cables (MC)

- UL 44, Thermoset Insulated Wires and Cables

- UL 1685 / FT4, Vertical Tray Flame Test rated

- IEEE 1202 / 383 (70,000 BTU / hr), Vertical Flame Test rated

- ICEA T-30-520 (70,000 BTU / hr), Vertical Flame Test rated

- XLPE (XHHW-2 rated), 90°C wet / dry

- UV sunlight resistant SUN RES (all colours)

- (Direct burial rated)

- -40°C cold bend rated

- Rated for use in hazardous locations:

- Class I Zone 2 (Div 2)

- Class II Zone 20, 21 (Div 1)

- Class II Zone 22 (Div 2)

Colour Coding

- 3C Black, # coded

- Method 4 (optional)

![]()

- Tri-sectional Grounding Conductors

- Stranded Bare (ASTM B8) Annealed Copper Conductors

- FR XLPE (XHHW-2 Rated) Insulated Conductors

- Polypropylene Fillers

- Polyester Separator Tape

- Dual Helically Applied Bare / Tinned Copper Tape Shield

- FR PVC Inner Protective Jacket

- Aluminum Interlocked Armor (AIA) (standard)

- FR PVC Outer Protective Jacket

| Part Number | Number of Conductors | Conductor Size (AWG/MCM) | Ground Wire Size (uninsulated) (AWG/MCM) | OD Over Inner Jacket (in/mm) | Nominal Diameters | Cable Weight (lbs/1000ft)/ (kg/km) | Ampacity (30°Cambient) | Max. Pulling Tension (Pulling Eye) (lb/kg) | Min. Bend Radius (Pull) (in/mm) | |

| Over Armour (in/mm) | Overall Cable (in/mm) | |||||||||

| 2C61HU1203007DR | 3 | 12 | 16 | 0.439 / 11.14 | 0.678 / 17.23 | 0.798 / 20.28 | 386 / 574 | 30 | 157 / 71 | 14.4 / 365 |

| 2C61HU1003007DR | 3 | 10 | 14 | 0.5 / 12.71 | 0.74 / 18.81 | 0.9 / 22.87 | 538 / 800 | 40 | 249 / 113 | 16.2 / 412 |

| 2C61HU0803007DR | 3 | 8 | 14 | 0.657 / 16.69 | 0.897 / 22.79 | 1.057 / 26.86 | 769 / 1144 | 55 | 397 / 180 | 19 / 483 |

| 2C613U0603007DR | 3 | 6 | 12 | 0.737 / 18.71 | 0.977 / 24.81 | 1.137 / 28.87 | 982 / 1462 | 75 | 629 / 285 | 20.5 / 520 |

| 2C613U0403007DR | 3 | 4 | 12 | 0.838 / 21.28 | 1.042 / 26.46 | 1.202 / 30.52 | 1256 / 1870 | 95 | 1002 / 454 | 21.6 / 549 |

| 2C613U0203007DR | 3 | 2 | 10 | 1.003 / 25.46 | 1.207 / 30.65 | 1.367 / 34.71 | 1755 / 2612 | 130 | 1593 / 723 | 24.6 / 625 |

| 2C613U0103407DR | 3 | 1 | 10 | 1.129 / 28.69 | 1.334 / 33.87 | 1.493 / 37.93 | 2125 / 3163 | 145 | 2009 / 911 | 26.9 / 683 |

| 2C613U1/03407DR | 3 | 1/0 | 10 | 1.215 / 30.87 | 1.42 / 36.06 | 1.579 / 40.12 | 2498 / 3717 | 170 | 2534 / 1150 | 28.4 / 722 |

| 2C613U2/03407DR | 3 | 2/0 | 10 | 1.308 / 33.22 | 1.512 / 38.4 | 1.672 / 42.46 | 2922 / 4348 | 195 | 3194 / 1449 | 30.1 / 764 |

| 2C613U3/03407DR | 3 | 3/0 | 8 | 1.417 / 36 | 1.622 / 41.19 | 1.842 / 46.78 | 3621 / 5389 | 225 | 4007 / 1818 | 33.1 / 842 |

| 2C613U4/03407DR | 3 | 4/0 | 8 | 1.538 / 39.06 | 1.742 / 44.24 | 1.962 / 49.83 | 4296 / 6393 | 260 | 5078 / 2304 | 35.3 / 897 |

| 2C613U2503607DR | 3 | 250 | 8 | 1.68 / 42.67 | 1.985 / 50.41 | 2.205 / 56 | 5194 / 7730 | 290 | 6000 / 2722 | 39.7 / 1008 |

| 2C613U3503607DR | 3 | 350 | 6 | 1.961 / 49.82 | 2.266 / 57.57 | 2.486 / 63.16 | 6960 / 10358 | 350 | 8400 / 3810 | 44.8 / 1137 |

| 2C613U5003607DR | 3 | 500 | 6 | 2.236 / 56.81 | 2.542 / 64.55 | 2.822 / 71.67 | 9325 / 13877 | 430 | 12000 / 5443 | 50.8 / 1290 |

| 2C613U7503607DR | 3 | 750 | 4 | 2.686 / 68.22 | 2.991 / 75.96 | 3.271 / 83.08 | 13110 / 19509 | 535 | 18000 / 8165 | 58.9 / 1495 |

*Ampacity value based on National Electrical Code, Version 2020, Table 310.16. Values are corrected according to Table 310.15(C)(1) for number of Conductors.

- Transit

- Water/Waste Water Treatment

- Generation

- Communication Power & Control

- Generation – Nuclear

- Power Distribution

- Industrial Construction/Automation

- Civil Construction Projects

- Industrial

- Generation – Renewables

- Petrochem/Pulp & Paper

- Utility

- Commercial Construction Projects

- OIl & Gas

- Mining

Related products

-

UL EPR RHW-2 | Single Conductor (600V)

Read moreUL EPR RHW-2 | Single Conductor (600V)

For use in open wiring and raceways (with the exception of cable troughs and ventilated flexible cableways) in dry or wet locations. For open wiring exposed to the weather. Maximum conductor temperature 90°C.

SKU: 1667 Categories: CSA Type TC Tray Cable, UL Type TC Tray Cable, Building WireUL EPR RHW-2 | Single Conductor (600V)

For use in open wiring and raceways (with the exception of cable troughs and ventilated flexible cableways) in dry or wet locations. For open wiring exposed to the weather. Maximum conductor temperature 90°C.

MORE DETAILS -

CSA RW90 | Single Conductor (600V)

Read moreCSA RW90 | Single Conductor (600V)

For use in open wiring and raceways (with the exception of cable troughs and ventilated flexible cableways) in dry or wet locations. For open wiring exposed to the weather. Maximum conductor temperature 90°C.

SKU: 1720 Categories: CSA Type ACIC Armoured Control & Instrumentation, Building WireCSA RW90 | Single Conductor (600V)

For use in open wiring and raceways (with the exception of cable troughs and ventilated flexible cableways) in dry or wet locations. For open wiring exposed to the weather. Maximum conductor temperature 90°C.

MORE DETAILS -

UL Metal Clad Armored AIA Power | Multi-Conductor (600/1000V)

Read moreUL Metal Clad Armored AIA Power | Multi-Conductor (600/1000V)

Metal-clad AIA power cables are suitable for use in ventilated, non-ventilated and ladder-type cable trays, direct burial, raceways and for exposed or concealed wiring in wet, damp or dry locations in -40°C (40°F) environments. Applicable for use in utility, industrial and commercial applications.

SKU: 1753 Categories: UL Type MC Metal Clad Cable, UL Type TC Tray Cable, Building WireUL Metal Clad Armored AIA Power | Multi-Conductor (600/1000V)

Metal-clad AIA power cables are suitable for use in ventilated, non-ventilated and ladder-type cable trays, direct burial, raceways and for exposed or concealed wiring in wet, damp or dry locations in -40°C (40°F) environments. Applicable for use in utility, industrial and commercial applications.

MORE DETAILS