CSA Safe-T-Ground, Single Conductor, 1000 V

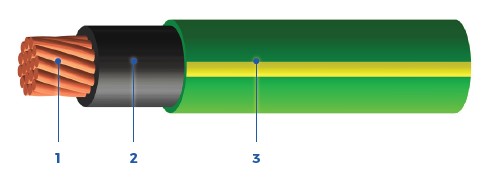

Construction

VOLTAGE

1000 V

Optional: 600, 2000 V

PRODUCT CONSTRUCTION

Insulation:

XLPE (RW90 rated) rated: 90°C wet/dry

Jacket:

FR PVC outer green jacket rated: 90°C to -40°C

Available in:

Custom insulation/jacket colours

Aluminum conductors

Solid green or green dual yellow SAFET-STRIPES for instrumentation/isolated grounding identification

Certifications

CERTIFICATION/COMPLIANCES

- CSA C22.2 No. 230, Tray cables

- CSA C22.2 No. 38, Thermoset-insulated wires and cables

- CSA C22.2 No. 2556 / UL 2556 FT4, Vertical Tray Flame Test rated

- IEEE 383/1202 (70,000 BTU/hr), Vertical Flame Test rated

- XLPE (RW90 rated), 90°C wet/dry

- UV sunlight resistant “SUN RES” (all colours)

- Oil resistant “PR I” and “OIL RES”

- Direct burial rated

- -40°C cold bend/impact rated

- Rated for use in hazardous locations:

- Zone 0 (Class 1, Division 1) (Intrinsically Safe circuits only)

- Zone 2 (Class I, Division 2)

- Zone 22 (Class II & III, Division 2)

COLOUR CODING

- Black conductor (standard)

Properties

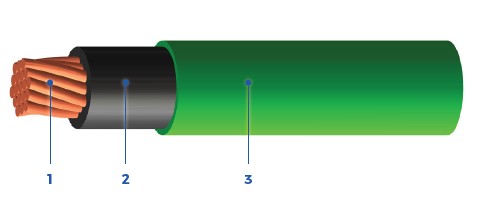

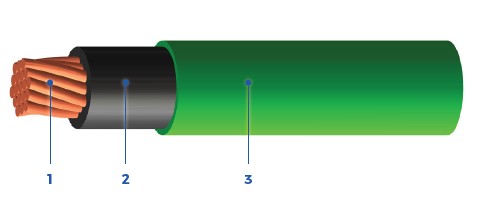

- Stranded Bare (ASTM B8) Annealed Copper Conductors

- XLPE (RW90 Rated) Insulated Conductor

- FR PVC Outer Green Protective jacket

GREEN CONDUCTOR

| Part Number | Number of Conductors | Conductor Size | Nominal Diameter Overall Cable | Cable Weight | Ampacity* | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) |

| AWG | in. | mm | lbs/1000ft | kg|km |

30°C ambient | lb | kg | in. | mm | ||

| 4D010M08010G000 | 1 | 8 | 0.307 | 7.8 | 82 | 122 | 80 | 132 | 60 | 2.8 | 70 |

| 4D010M06010G000 | 1 | 6 | 0.374 | 9.5 | 126 | 188 | 105 | 210 | 95 | 3.4 | 85 |

| 4D010M04010G000 | 1 | 4 | 0.421 | 10.7 | 182 | 271 | 140 | 334 | 151 | 3.8 | 96 |

| 4D010M03010G000 | 1 | 3 | 0.448 | 11.4 | 221 | 329 | 165 | 421 | 191 | 4.0 | 102 |

| 4D010M02010G000 | 1 | 2 | 0.479 | 12.2 | 269 | 400 | 190 | 531 | 241 | 4.3 | 109 |

| 4D010M01014G000 | 1 | 1 | 0.588 | 14.9 | 364 | 542 | 220 | 670 | 304 | 5.3 | 134 |

| 4D010M1/014G000 | 1 | 1/0 | 0.628 | 16.0 | 443 | 659 | 260 | 845 | 383 | 5.7 | 144 |

| 4D010M2/014G000 | 1 | 2/0 | 0.671 | 17.0 | 539 | 803 | 300 | 1065 | 483 | 6.0 | 153 |

| 4D010M3/014G000 | 1 | 3/0 | 0.722 | 18.3 | 661 | 984 | 350 | 1336 | 606 | 6.5 | 165 |

| 4D010M4/014G000 | 1 | 4/0 | 0.778 | 19.8 | 812 | 1209 | 405 | 1693 | 768 | 7.0 | 178 |

| 4D010M25016G000 | 1 | 250 | 0.884 | 22.5 | 975 | 1450 | 455 | 2000 | 907 | 8.0 | 202 |

| 4D010M35016G000 | 1 | 350 | 0.987 | 25.1 | 1316 | 1958 | 570 | 2800 | 1270 | 8.9 | 226 |

| 4D010M50016G000 | 1 | 500 | 1.115 | 28.3 | 1819 | 2707 | 700 | 4000 | 1814 | 10.0 | 255 |

| 4D010M75016G000 | 1 | 750 | 1.294 | 32.0 | 2650 | 3944 | 885 | 6000 | 2722 | 11.6 | 296 |

*Ampacity value based on Canadian Electrical Code, Part 1 (2024 25th Edition), Table 1.

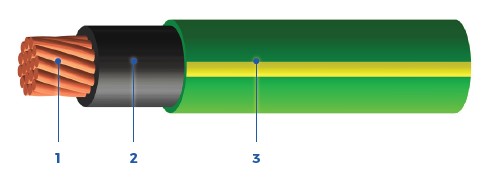

- Stranded Bare (ASTM B8) Annealed Copper Conductors

- XLPE (RW90 Rated) Insulated Conductor

- FR PVC Outer Green with Dual Yellow SAFE-T- STRIPES Protective Jacket

SAFE-T-STRIPE CONDUCTOR

| Part Number | Number of Conductors | Conductor Size | Nominal Diameter Overall Cable | Cable Weight | Ampacity* | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) |

| AWG | in. | mm | lbs|1000ft | kg|km |

30°C ambient | lb | kg | in. | mm | ||

| 4D010M08010G00Y | 1 | 8 | 0.307 | 7.8 | 82 | 123 | 80 | 132 | 60 | 2.8 | 70 |

| 4D010M06010G00Y | 1 | 6 | 0.374 | 9.5 | 126 | 188 | 105 | 210 | 95 | 3.4 | 85 |

| 4D010M04010G00Y | 1 | 4 | 0.421 | 10.7 | 183 | 272 | 140 | 334 | 151 | 3.8 | 96 |

| 4D010M03010G00Y | 1 | 3 | 0.448 | 11.4 | 221 | 329 | 165 | 421 | 191 | 4.0 | 102 |

| 4D010M02010G00Y | 1 | 2 | 0.479 | 12.2 | 269 | 401 | 190 | 531 | 241 | 4.3 | 109 |

| 4D010M01014G00Y | 1 | 1 | 0.588 | 14.9 | 365 | 543 | 220 | 670 | 304 | 5.3 | 134 |

| 4D010M1/014G00Y | 1 | 1/0 | 0.628 | 16.0 | 443 | 659 | 260 | 845 | 383 | 5.7 | 144 |

| 4D010M2/014G00Y | 1 | 2/0 | 0.671 | 17.0 | 540 | 804 | 300 | 1065 | 483 | 6.0 | 153 |

| 4D010M3/014G00Y | 1 | 3/0 | 0.722 | 18.3 | 662 | 985 | 350 | 1336 | 606 | 6.5 | 165 |

| 4D010M4/014G00Y | 1 | 4/0 | 0.778 | 19.8 | 813 | 1210 | 405 | 1693 | 768 | 7.0 | 178 |

| 4D010M25016G00Y | 1 | 250 | 0.884 | 22.5 | 976 | 1452 | 455 | 2000 | 907 | 8.0 | 202 |

| 4D010M35016G00Y | 1 | 350 | 0.987 | 25.1 | 1317 | 1960 | 570 | 2800 | 1270 | 8.9 | 226 |

| 4D010M50016G00Y | 1 | 500 | 1.115 | 28.3 | 1821 | 2709 | 700 | 4000 | 1814 | 10.0 | 255 |

| 4D010M75016G00Y | 1 | 750 | 1.294 | 32.9 | 2652 | 3946 | 885 | 6000 | 2722 | 11.6 | 296 |

*Ampacity value based on Canadian Electrical Code, Part 1 (2024 25th Edition), Table 1.

Markets / Applications

- Generation – Renewables – Wind

- Transit

- Water/Waste Water Treatment

- Shipboard

- Generation – Traditional Power

- Generation

- Communication Power & Control

- Generation – Nuclear

- Power Distribution

- Industrial Construction/Automation

- Civil Construction Projects

- Power Distribution – LV

- Industrial

- Generation – Renewables

- Petrochem/Pulp & Paper

- Utility

- Commercial Construction Projects

- Generation – Renewables – Geo Thermal

- Generation – Renewables – Solar

- Mining

VOLTAGE

1000 V

Optional: 600, 2000 V

PRODUCT CONSTRUCTION

Insulation:

XLPE (RW90 rated) rated: 90°C wet/dry

Jacket:

FR PVC outer green jacket rated: 90°C to -40°C

Available in:

Custom insulation/jacket colours

Aluminum conductors

Solid green or green dual yellow SAFET-STRIPES for instrumentation/isolated grounding identification

CERTIFICATION/COMPLIANCES

- CSA C22.2 No. 230, Tray cables

- CSA C22.2 No. 38, Thermoset-insulated wires and cables

- CSA C22.2 No. 2556 / UL 2556 FT4, Vertical Tray Flame Test rated

- IEEE 383/1202 (70,000 BTU/hr), Vertical Flame Test rated

- XLPE (RW90 rated), 90°C wet/dry

- UV sunlight resistant “SUN RES” (all colours)

- Oil resistant “PR I” and “OIL RES”

- Direct burial rated

- -40°C cold bend/impact rated

- Rated for use in hazardous locations:

- Zone 0 (Class 1, Division 1) (Intrinsically Safe circuits only)

- Zone 2 (Class I, Division 2)

- Zone 22 (Class II & III, Division 2)

COLOUR CODING

- Black conductor (standard)

- Stranded Bare (ASTM B8) Annealed Copper Conductors

- XLPE (RW90 Rated) Insulated Conductor

- FR PVC Outer Green Protective jacket

GREEN CONDUCTOR

| Part Number | Number of Conductors | Conductor Size | Nominal Diameter Overall Cable | Cable Weight | Ampacity* | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) |

| AWG | in. | mm | lbs/1000ft | kg|km |

30°C ambient | lb | kg | in. | mm | ||

| 4D010M08010G000 | 1 | 8 | 0.307 | 7.8 | 82 | 122 | 80 | 132 | 60 | 2.8 | 70 |

| 4D010M06010G000 | 1 | 6 | 0.374 | 9.5 | 126 | 188 | 105 | 210 | 95 | 3.4 | 85 |

| 4D010M04010G000 | 1 | 4 | 0.421 | 10.7 | 182 | 271 | 140 | 334 | 151 | 3.8 | 96 |

| 4D010M03010G000 | 1 | 3 | 0.448 | 11.4 | 221 | 329 | 165 | 421 | 191 | 4.0 | 102 |

| 4D010M02010G000 | 1 | 2 | 0.479 | 12.2 | 269 | 400 | 190 | 531 | 241 | 4.3 | 109 |

| 4D010M01014G000 | 1 | 1 | 0.588 | 14.9 | 364 | 542 | 220 | 670 | 304 | 5.3 | 134 |

| 4D010M1/014G000 | 1 | 1/0 | 0.628 | 16.0 | 443 | 659 | 260 | 845 | 383 | 5.7 | 144 |

| 4D010M2/014G000 | 1 | 2/0 | 0.671 | 17.0 | 539 | 803 | 300 | 1065 | 483 | 6.0 | 153 |

| 4D010M3/014G000 | 1 | 3/0 | 0.722 | 18.3 | 661 | 984 | 350 | 1336 | 606 | 6.5 | 165 |

| 4D010M4/014G000 | 1 | 4/0 | 0.778 | 19.8 | 812 | 1209 | 405 | 1693 | 768 | 7.0 | 178 |

| 4D010M25016G000 | 1 | 250 | 0.884 | 22.5 | 975 | 1450 | 455 | 2000 | 907 | 8.0 | 202 |

| 4D010M35016G000 | 1 | 350 | 0.987 | 25.1 | 1316 | 1958 | 570 | 2800 | 1270 | 8.9 | 226 |

| 4D010M50016G000 | 1 | 500 | 1.115 | 28.3 | 1819 | 2707 | 700 | 4000 | 1814 | 10.0 | 255 |

| 4D010M75016G000 | 1 | 750 | 1.294 | 32.0 | 2650 | 3944 | 885 | 6000 | 2722 | 11.6 | 296 |

*Ampacity value based on Canadian Electrical Code, Part 1 (2024 25th Edition), Table 1.

- Stranded Bare (ASTM B8) Annealed Copper Conductors

- XLPE (RW90 Rated) Insulated Conductor

- FR PVC Outer Green with Dual Yellow SAFE-T- STRIPES Protective Jacket

SAFE-T-STRIPE CONDUCTOR

| Part Number | Number of Conductors | Conductor Size | Nominal Diameter Overall Cable | Cable Weight | Ampacity* | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) |

| AWG | in. | mm | lbs|1000ft | kg|km |

30°C ambient | lb | kg | in. | mm | ||

| 4D010M08010G00Y | 1 | 8 | 0.307 | 7.8 | 82 | 123 | 80 | 132 | 60 | 2.8 | 70 |

| 4D010M06010G00Y | 1 | 6 | 0.374 | 9.5 | 126 | 188 | 105 | 210 | 95 | 3.4 | 85 |

| 4D010M04010G00Y | 1 | 4 | 0.421 | 10.7 | 183 | 272 | 140 | 334 | 151 | 3.8 | 96 |

| 4D010M03010G00Y | 1 | 3 | 0.448 | 11.4 | 221 | 329 | 165 | 421 | 191 | 4.0 | 102 |

| 4D010M02010G00Y | 1 | 2 | 0.479 | 12.2 | 269 | 401 | 190 | 531 | 241 | 4.3 | 109 |

| 4D010M01014G00Y | 1 | 1 | 0.588 | 14.9 | 365 | 543 | 220 | 670 | 304 | 5.3 | 134 |

| 4D010M1/014G00Y | 1 | 1/0 | 0.628 | 16.0 | 443 | 659 | 260 | 845 | 383 | 5.7 | 144 |

| 4D010M2/014G00Y | 1 | 2/0 | 0.671 | 17.0 | 540 | 804 | 300 | 1065 | 483 | 6.0 | 153 |

| 4D010M3/014G00Y | 1 | 3/0 | 0.722 | 18.3 | 662 | 985 | 350 | 1336 | 606 | 6.5 | 165 |

| 4D010M4/014G00Y | 1 | 4/0 | 0.778 | 19.8 | 813 | 1210 | 405 | 1693 | 768 | 7.0 | 178 |

| 4D010M25016G00Y | 1 | 250 | 0.884 | 22.5 | 976 | 1452 | 455 | 2000 | 907 | 8.0 | 202 |

| 4D010M35016G00Y | 1 | 350 | 0.987 | 25.1 | 1317 | 1960 | 570 | 2800 | 1270 | 8.9 | 226 |

| 4D010M50016G00Y | 1 | 500 | 1.115 | 28.3 | 1821 | 2709 | 700 | 4000 | 1814 | 10.0 | 255 |

| 4D010M75016G00Y | 1 | 750 | 1.294 | 32.9 | 2652 | 3946 | 885 | 6000 | 2722 | 11.6 | 296 |

*Ampacity value based on Canadian Electrical Code, Part 1 (2024 25th Edition), Table 1.

- Generation – Renewables – Wind

- Transit

- Water/Waste Water Treatment

- Shipboard

- Generation – Traditional Power

- Generation

- Communication Power & Control

- Generation – Nuclear

- Power Distribution

- Industrial Construction/Automation

- Civil Construction Projects

- Power Distribution – LV

- Industrial

- Generation – Renewables

- Petrochem/Pulp & Paper

- Utility

- Commercial Construction Projects

- Generation – Renewables – Geo Thermal

- Generation – Renewables – Solar

- Mining