CSA TYPE CIC TC Tray Instrumentation, 300 V

Tray Instrumentation cables can be used to minimize noise and signal interference by preventing crosstalk between pairs and triads. This cable can also be used to convert analogue or digital signals. Type TC Instrumentation cables can be installed in raceways, cable trays, direct burial applications and in outdoor exposed industrial applications.

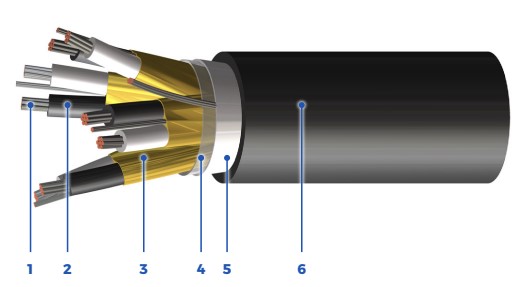

Construction

Voltage

300 V

Optional: 600, 1000 V

Product Construction

- Insulation:

- XLPE (RW90 rated) rated: 90°C wet / 105°C dry

- PVC (optional)

- Shielding (foil-free edge):

- ISOS (standard)

- OS (optional)

- Jacket:

- FR PVC outer black jacket rated: 90°C to -40°C

- Available in:

- Copper tape or braided shield

- Custom insulation / jacket colours

- Composite constructions

Certifications

Certifications/Compliances

- CSA C22.2 No. 230, Tray cables

- CSA C22.2 No. 239, Control & Instrumentation cables

- CSA C22.2 No. 38, Thermoset-insulated wires and cables

- CSA C22.2 No. 75, Thermoplastic-insulated wires and cables

- CSA C22.2 No. 2556 / UL 2556 FT4, Vertical Tray Flame Test rated

- IEEE 383/1202 (70,000 BTU / hr), Vertical Flame Test rated

- XLPE (RW90 rated), 90°C wet / 105°C dry

- UV sunlight resistant SUN RES (all colours)

- Direct burial rated

- -40°C cold bend / impact rated

- Rated for use in hazardous locations:

- Zone 0 (Class 1, Division 1) (Intrinsically Safe circuits only)

- Zone 2 (Class I, Division 2)

- Zone 22 (Class II & III, Division 2)

- TC-BCD gas groups rated

Colour Coding

- Pairs – Black, & white, number-coded with black ink printed on white conductor (standard)

- Triads – Black, white & red, number-coded with black ink printed on white conductor (standard)

Properties

- Stranded Bare Copper Conductors (Tin-coated Available)

- XLPE (RW90 Rated) Insulated Conductors

- Individually Shielded Pairs / Triads with Tin-coated Copper Drain Wire

- Polyester Separator Tape

- Overall Aluminum / Mylar Shield with Tin-coated Copper Drain Wire

- FR PVC Outer Protective Jacket

PAIRS

| Part Number | Number of Pairs | Conductor Size | Nominal Diameter Overall Cable | Cable Weight | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) |

| AWG | in. | mm | lbs|1000ft | kg|km | lb | kg | in. | mm | ||

| 4B021M160100008 | 1 | 16 | 0.347 | 8.8 | 56 | 84 | 41 | 19 | 6.2 | 159 |

| 4B022M160200008 | 2 | 16 | 0.514 | 13.1 | 125 | 186 | 82 | 37 | 9.3 | 235 |

| 4B022M160400008 | 4 | 16 | 0.632 | 16.1 | 195 | 290 | 165 | 75 | 11.4 | 289 |

| 4B022M160600008 | 6 | 16 | 0.756 | 19.2 | 280 | 416 | 247 | 112 | 13.6 | 346 |

| 4B022M160800008 | 8 | 16 | 0.821 | 20.9 | 346 | 515 | 330 | 150 | 14.8 | 375 |

| 4B022M161200008 | 12 | 16 | 1.042 | 26.5 | 528 | 786 | 494 | 224 | 18.7 | 476 |

| 4B022M161600008 | 16 | 16 | 1.160 | 29.5 | 663 | 986 | 659 | 299 | 20.9 | 530 |

| 4B022M162400008 | 24 | 16 | 1.438 | 36.5 | 961 | 1431 | 989 | 449 | 25.9 | 658 |

| 4B022M163600008 | 36 | 16 | 1.657 | 42.1 | 1357 | 2019 | 1483 | 673 | 29.8 | 758 |

| 4B022M180200008 | 2 | 18 | 0.475 | 12.1 | 99 | 147 | 52 | 24 | 8.5 | 217 |

| 4B022M180400008 | 4 | 18 | 0.584 | 14.8 | 151 | 225 | 104 | 47 | 10.5 | 267 |

| 4B022M180600008 | 6 | 18 | 0.696 | 17.7 | 215 | 319 | 156 | 71 | 12.5 | 318 |

| 4B022M180800008 | 8 | 18 | 0.754 | 19.2 | 263 | 392 | 208 | 94 | 13.6 | 345 |

| 4B022M181200008 | 12 | 18 | 0.957 | 24.3 | 401 | 597 | 312 | 142 | 17.2 | 438 |

| 4B022M181600008 | 16 | 18 | 1.064 | 27.0 | 499 | 742 | 416 | 189 | 19.2 | 487 |

| 4B022M182400008 | 24 | 18 | 1.315 | 33.4 | 716 | 1065 | 624 | 283 | 23.7 | 601 |

| 4B022M183600008 | 36 | 18 | 1.512 | 38.4 | 997 | 1484 | 936 | 425 | 27.2 | 692 |

| 4B021M200100008 | 1 | 20 | 0.303 | 7.7 | 39 | 57 | 16 | 7 | 5.5 | 139 |

| 4B022M200200008 | 2 | 20 | 0.442 | 11.2 | 84 | 125 | 32 | 15 | 8.0 | 202 |

| 4B022M200400008 | 4 | 20 | 0.514 | 13.1 | 113 | 169 | 64 | 29 | 9.3 | 235 |

| 4B022M200600008 | 6 | 20 | 0.646 | 16.4 | 178 | 264 | 96 | 44 | 11.6 | 295 |

| 4B022M200800008 | 8 | 20 | 0.699 | 17.8 | 215 | 320 | 128 | 58 | 12.6 | 320 |

| 4B022M201200008 | 12 | 20 | 0.887 | 22.5 | 330 | 491 | 192 | 87 | 16.0 | 406 |

| 4B022M201600008 | 16 | 20 | 0.984 | 25.0 | 405 | 603 | 256 | 116 | 17.7 | 450 |

| 4B022M202400008 | 24 | 20 | 1.213 | 30.8 | 579 | 861 | 384 | 174 | 21.8 | 554 |

| 4B022M203600008 | 36 | 20 | 1.392 | 35.4 | 798 | 1188 | 576 | 261 | 25.1 | 636 |

TRIADS

| Part Number | Number of Pairs | Conductor Size | Nominal Diameter Overall Cable | Cable Weight | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) |

| AWG | in. | mm | lbs|1000ft | kg|km |

lb | kg | in. | mm | ||

| 4B031M160100008 | 1 | 16 | 0.365 | 9.3 | 71 | 106 | 62 | 28 | 6.6 | 167 |

| 4B032M160200008 | 2 | 16 | 0.615 | 15.6 | 178 | 265 | 124 | 56 | 11.1 | 281 |

| 4B032M160400008 | 4 | 16 | 0.718 | 18.2 | 258 | 383 | 247 | 112 | 12.9 | 328 |

| 4B032M160600008 | 6 | 16 | 0.903 | 22.9 | 403 | 600 | 371 | 168 | 16.3 | 413 |

| 4B032M160800008 | 8 | 16 | 0.978 | 24.8 | 499 | 743 | 494 | 224 | 17.6 | 447 |

| 4B032M161200008 | 12 | 16 | 1.188 | 30.2 | 711 | 1058 | 742 | 336 | 21.4 | 543 |

| 4B032M161600008 | 16 | 16 | 1.326 | 33.7 | 896 | 1333 | 989 | 449 | 23.9 | 606 |

| 4B032M162400008 | 24 | 16 | 1.651 | 41.9 | 1310 | 1949 | 1483 | 673 | 29.7 | 755 |

| 4B031M180100008 | 1 | 18 | 0.339 | 8.6 | 56 | 83 | 39 | 18 | 6.1 | 155 |

| 4B032M180200008 | 2 | 18 | 0.568 | 14.4 | 142 | 211 | 78 | 35 | 10.2 | 260 |

| 4B032M180400008 | 4 | 18 | 0.661 | 16.8 | 199 | 297 | 156 | 71 | 11.9 | 302 |

| 4B032M180600008 | 6 | 18 | 0.791 | 20.1 | 286 | 425 | 234 | 106 | 14.2 | 362 |

| 4B032M180800008 | 8 | 18 | 0.899 | 22.8 | 385 | 572 | 312 | 142 | 16.2 | 411 |

| 4B032M181200008 | 12 | 18 | 1.089 | 27.7 | 543 | 807 | 468 | 212 | 19.6 | 498 |

| 4B032M181600008 | 16 | 18 | 1.213 | 30.8 | 676 | 1006 | 624 | 283 | 21.8 | 555 |

| 4B032M182400008 | 24 | 18 | 1.506 | 38.2 | 979 | 1457 | 936 | 425 | 27.1 | 688 |

| 4B031M200100008 | 1 | 20 | 0.318 | 8.1 | 46 | 69 | 24 | 11 | 5.7 | 145 |

| 4B032M200200008 | 2 | 20 | 0.500 | 12.7 | 106 | 158 | 48 | 22 | 9.0 | 229 |

| 4B032M200400008 | 4 | 20 | 0.615 | 15.6 | 162 | 242 | 96 | 44 | 11.1 | 281 |

| 4B032M200800008 | 8 | 20 | 0.796 | 20.2 | 282 | 419 | 192 | 87 | 14.3 | 364 |

| 4B032M201200008 | 12 | 20 | 1.009 | 25.6 | 431 | 641 | 288 | 131 | 18.2 | 461 |

| 4B032M201600008 | 16 | 20 | 1.122 | 28.5 | 534 | 795 | 384 | 174 | 20.2 | 513 |

| 4B032M202400008 | 24 | 20 | 1.388 | 35.3 | 769 | 1144 | 576 | 261 | 25.0 | 635 |

Markets / Applications

- Water/Waste Water Treatment

- Industrial Construction/Automation

- Industrial

- Petrochem/Pulp & Paper

- Utility

- Energy

- Mining

Voltage

300 V

Optional: 600, 1000 V

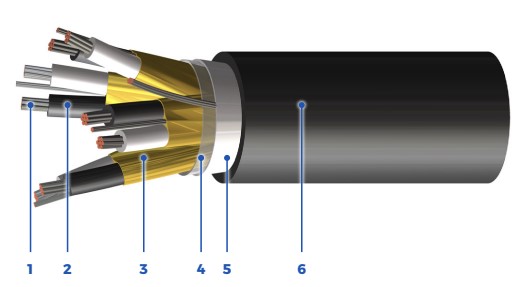

Product Construction

- Insulation:

- XLPE (RW90 rated) rated: 90°C wet / 105°C dry

- PVC (optional)

- Shielding (foil-free edge):

- ISOS (standard)

- OS (optional)

- Jacket:

- FR PVC outer black jacket rated: 90°C to -40°C

- Available in:

- Copper tape or braided shield

- Custom insulation / jacket colours

- Composite constructions

Certifications/Compliances

- CSA C22.2 No. 230, Tray cables

- CSA C22.2 No. 239, Control & Instrumentation cables

- CSA C22.2 No. 38, Thermoset-insulated wires and cables

- CSA C22.2 No. 75, Thermoplastic-insulated wires and cables

- CSA C22.2 No. 2556 / UL 2556 FT4, Vertical Tray Flame Test rated

- IEEE 383/1202 (70,000 BTU / hr), Vertical Flame Test rated

- XLPE (RW90 rated), 90°C wet / 105°C dry

- UV sunlight resistant SUN RES (all colours)

- Direct burial rated

- -40°C cold bend / impact rated

- Rated for use in hazardous locations:

- Zone 0 (Class 1, Division 1) (Intrinsically Safe circuits only)

- Zone 2 (Class I, Division 2)

- Zone 22 (Class II & III, Division 2)

- TC-BCD gas groups rated

Colour Coding

- Pairs – Black, & white, number-coded with black ink printed on white conductor (standard)

- Triads – Black, white & red, number-coded with black ink printed on white conductor (standard)

- Stranded Bare Copper Conductors (Tin-coated Available)

- XLPE (RW90 Rated) Insulated Conductors

- Individually Shielded Pairs / Triads with Tin-coated Copper Drain Wire

- Polyester Separator Tape

- Overall Aluminum / Mylar Shield with Tin-coated Copper Drain Wire

- FR PVC Outer Protective Jacket

PAIRS

| Part Number | Number of Pairs | Conductor Size | Nominal Diameter Overall Cable | Cable Weight | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) |

| AWG | in. | mm | lbs|1000ft | kg|km | lb | kg | in. | mm | ||

| 4B021M160100008 | 1 | 16 | 0.347 | 8.8 | 56 | 84 | 41 | 19 | 6.2 | 159 |

| 4B022M160200008 | 2 | 16 | 0.514 | 13.1 | 125 | 186 | 82 | 37 | 9.3 | 235 |

| 4B022M160400008 | 4 | 16 | 0.632 | 16.1 | 195 | 290 | 165 | 75 | 11.4 | 289 |

| 4B022M160600008 | 6 | 16 | 0.756 | 19.2 | 280 | 416 | 247 | 112 | 13.6 | 346 |

| 4B022M160800008 | 8 | 16 | 0.821 | 20.9 | 346 | 515 | 330 | 150 | 14.8 | 375 |

| 4B022M161200008 | 12 | 16 | 1.042 | 26.5 | 528 | 786 | 494 | 224 | 18.7 | 476 |

| 4B022M161600008 | 16 | 16 | 1.160 | 29.5 | 663 | 986 | 659 | 299 | 20.9 | 530 |

| 4B022M162400008 | 24 | 16 | 1.438 | 36.5 | 961 | 1431 | 989 | 449 | 25.9 | 658 |

| 4B022M163600008 | 36 | 16 | 1.657 | 42.1 | 1357 | 2019 | 1483 | 673 | 29.8 | 758 |

| 4B022M180200008 | 2 | 18 | 0.475 | 12.1 | 99 | 147 | 52 | 24 | 8.5 | 217 |

| 4B022M180400008 | 4 | 18 | 0.584 | 14.8 | 151 | 225 | 104 | 47 | 10.5 | 267 |

| 4B022M180600008 | 6 | 18 | 0.696 | 17.7 | 215 | 319 | 156 | 71 | 12.5 | 318 |

| 4B022M180800008 | 8 | 18 | 0.754 | 19.2 | 263 | 392 | 208 | 94 | 13.6 | 345 |

| 4B022M181200008 | 12 | 18 | 0.957 | 24.3 | 401 | 597 | 312 | 142 | 17.2 | 438 |

| 4B022M181600008 | 16 | 18 | 1.064 | 27.0 | 499 | 742 | 416 | 189 | 19.2 | 487 |

| 4B022M182400008 | 24 | 18 | 1.315 | 33.4 | 716 | 1065 | 624 | 283 | 23.7 | 601 |

| 4B022M183600008 | 36 | 18 | 1.512 | 38.4 | 997 | 1484 | 936 | 425 | 27.2 | 692 |

| 4B021M200100008 | 1 | 20 | 0.303 | 7.7 | 39 | 57 | 16 | 7 | 5.5 | 139 |

| 4B022M200200008 | 2 | 20 | 0.442 | 11.2 | 84 | 125 | 32 | 15 | 8.0 | 202 |

| 4B022M200400008 | 4 | 20 | 0.514 | 13.1 | 113 | 169 | 64 | 29 | 9.3 | 235 |

| 4B022M200600008 | 6 | 20 | 0.646 | 16.4 | 178 | 264 | 96 | 44 | 11.6 | 295 |

| 4B022M200800008 | 8 | 20 | 0.699 | 17.8 | 215 | 320 | 128 | 58 | 12.6 | 320 |

| 4B022M201200008 | 12 | 20 | 0.887 | 22.5 | 330 | 491 | 192 | 87 | 16.0 | 406 |

| 4B022M201600008 | 16 | 20 | 0.984 | 25.0 | 405 | 603 | 256 | 116 | 17.7 | 450 |

| 4B022M202400008 | 24 | 20 | 1.213 | 30.8 | 579 | 861 | 384 | 174 | 21.8 | 554 |

| 4B022M203600008 | 36 | 20 | 1.392 | 35.4 | 798 | 1188 | 576 | 261 | 25.1 | 636 |

TRIADS

| Part Number | Number of Pairs | Conductor Size | Nominal Diameter Overall Cable | Cable Weight | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) |

| AWG | in. | mm | lbs|1000ft | kg|km |

lb | kg | in. | mm | ||

| 4B031M160100008 | 1 | 16 | 0.365 | 9.3 | 71 | 106 | 62 | 28 | 6.6 | 167 |

| 4B032M160200008 | 2 | 16 | 0.615 | 15.6 | 178 | 265 | 124 | 56 | 11.1 | 281 |

| 4B032M160400008 | 4 | 16 | 0.718 | 18.2 | 258 | 383 | 247 | 112 | 12.9 | 328 |

| 4B032M160600008 | 6 | 16 | 0.903 | 22.9 | 403 | 600 | 371 | 168 | 16.3 | 413 |

| 4B032M160800008 | 8 | 16 | 0.978 | 24.8 | 499 | 743 | 494 | 224 | 17.6 | 447 |

| 4B032M161200008 | 12 | 16 | 1.188 | 30.2 | 711 | 1058 | 742 | 336 | 21.4 | 543 |

| 4B032M161600008 | 16 | 16 | 1.326 | 33.7 | 896 | 1333 | 989 | 449 | 23.9 | 606 |

| 4B032M162400008 | 24 | 16 | 1.651 | 41.9 | 1310 | 1949 | 1483 | 673 | 29.7 | 755 |

| 4B031M180100008 | 1 | 18 | 0.339 | 8.6 | 56 | 83 | 39 | 18 | 6.1 | 155 |

| 4B032M180200008 | 2 | 18 | 0.568 | 14.4 | 142 | 211 | 78 | 35 | 10.2 | 260 |

| 4B032M180400008 | 4 | 18 | 0.661 | 16.8 | 199 | 297 | 156 | 71 | 11.9 | 302 |

| 4B032M180600008 | 6 | 18 | 0.791 | 20.1 | 286 | 425 | 234 | 106 | 14.2 | 362 |

| 4B032M180800008 | 8 | 18 | 0.899 | 22.8 | 385 | 572 | 312 | 142 | 16.2 | 411 |

| 4B032M181200008 | 12 | 18 | 1.089 | 27.7 | 543 | 807 | 468 | 212 | 19.6 | 498 |

| 4B032M181600008 | 16 | 18 | 1.213 | 30.8 | 676 | 1006 | 624 | 283 | 21.8 | 555 |

| 4B032M182400008 | 24 | 18 | 1.506 | 38.2 | 979 | 1457 | 936 | 425 | 27.1 | 688 |

| 4B031M200100008 | 1 | 20 | 0.318 | 8.1 | 46 | 69 | 24 | 11 | 5.7 | 145 |

| 4B032M200200008 | 2 | 20 | 0.500 | 12.7 | 106 | 158 | 48 | 22 | 9.0 | 229 |

| 4B032M200400008 | 4 | 20 | 0.615 | 15.6 | 162 | 242 | 96 | 44 | 11.1 | 281 |

| 4B032M200800008 | 8 | 20 | 0.796 | 20.2 | 282 | 419 | 192 | 87 | 14.3 | 364 |

| 4B032M201200008 | 12 | 20 | 1.009 | 25.6 | 431 | 641 | 288 | 131 | 18.2 | 461 |

| 4B032M201600008 | 16 | 20 | 1.122 | 28.5 | 534 | 795 | 384 | 174 | 20.2 | 513 |

| 4B032M202400008 | 24 | 20 | 1.388 | 35.3 | 769 | 1144 | 576 | 261 | 25.0 | 635 |

- Water/Waste Water Treatment

- Industrial Construction/Automation

- Industrial

- Petrochem/Pulp & Paper

- Utility

- Energy

- Mining