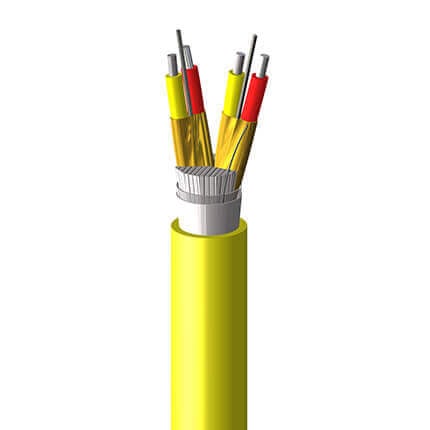

UL Unarmored Tray, TC-ER, VFD, XLPE/PVC | Multi-Conductor (600V)

Construction

Voltage

600 V

Product Construction

Conductor:

3 conductor, 14 AWG through 750 KCMIL in compliance with Class B strand ASTM B8, ASTM B3 or ASTM B33 with options available

Insulation:

Cross-linked Polyethylene (Type XHHW-2). 90°C DRY/WET

Ground:

Tri-sectional symmetrical grounds in contact with shield, in compliance with Class B strand ASTM B8, ASTM B3 or ASTM B33, options available

Metallic Shield:

Helically applied copper tape, 100% coverage*

Jacket:

Polyvinyl Chloride (PVC), Sunlight Resistant in all colors

* Single helically applied copper tape for size 8 and smaller

Certifications

Certification/Compliances

- UL 1277, Tray Cable (TC-ER)

- UL 44 Type XHHW-2

- IEEE 1202/FT4, UL 1685

- ICEA T-29-520

- SUN RES in all colors

- DIR BUR

- -40°C Cold Bend

- OIL RES I**

Color Coding

- Color-coded per ICEA Method 4, Individual conductors colored black with conductor number ink printed on surface

**6 AWG and smaller

Properties

|

| PART NUMBER | CONDUCTOR COUNT | CONDUCTOR SIZE | BARE GROUNDING CONDUCTOR | NOMINAL OVERALL DIAMETER OF CABLE | CABLE WEIGHT | AMPACITY 30°C AMBIENT | MAX. PULLING TENSION(PULLING EYE) | MIN. BEND RADIUS (PULL) |

| AWG | AWG | IN | LBS/1000FT | AMPS | LB | IN | ||

|

2V01HU1403002DR |

3C+ 3G |

14 |

3 X 18 |

0.40 |

130 |

25 |

99 |

7.21 |

|

2V01HU1203002DR |

3C+ 3G |

12 |

3 X 16 |

0.44 |

172 |

30 |

157 |

7.91 |

|

2V01HU1003002DR |

3C+ 3G |

10 |

3 X 14 |

0.50 |

255 |

40 |

249 |

9.02 |

|

2V01HU0803002DR |

3C+ 3G |

8 |

3 X 14 |

0.66 |

386 |

55 |

396 |

11.85 |

|

2V013U0603002DR |

3C+ 3G |

6 |

3 X 12 |

0.74 |

539 |

75 |

630 |

13.29 |

|

2C013U0403000DR |

3C+ 3G |

4 |

3 X 12 |

0.84 |

710 |

95 |

1002 |

15.11 |

|

2C013U0203000DR |

3C+ 3G |

2 |

3 X 10 |

1.00 |

1060 |

130 |

1593 |

18.08 |

|

2C013U0103400DR |

3C+ 3G |

1 |

3 X 10 |

1.13 |

1299 |

145 |

2009 |

20.37 |

|

2C013U1/03400DR |

3C+ 3G |

1/0 |

3 X 10 |

1.22 |

1549 |

170 |

2534 |

21.92 |

|

2C013U2/03400DR |

3C+ 3G |

2/0 |

3 X 10 |

1.31 |

1843 |

195 |

3194 |

23.59 |

|

2C013U3/03400DR |

3C+ 3G |

3/0 |

3 X 8 |

1.42 |

2267 |

225 |

4027 |

25.56 |

|

2C013U4/03400DR |

3C+ 3G |

4/0 |

3 X 8 |

1.54 |

2752 |

260 |

5078 |

27.73 |

|

2C013U2503600DR |

3C+ 3G |

250 |

3 X 8 |

1.74 |

3259 |

290 |

6000 |

31.37 |

|

2C013U3503600DR |

3C+ 3G |

350 |

3 X 6 |

1.96 |

4491 |

350 |

8400 |

35.37 |

|

2C013U5003600DR |

3C+ 3G |

500 |

3 X 6 |

2.24 |

5975 |

430 |

12000 |

40.33 |

|

2C013U7503600DR |

3C+ 3G |

750 |

3 X 4 |

2.69 |

8963 |

535 |

18000 |

48.44 |

*Ampacity value based on National Electrical Code, Version 2017, Table 3-10.15(B)(16).

Markets / Applications

This product does not currently have any associated applications. Please check back at a later date.

Voltage

600 V

Product Construction

Conductor:

3 conductor, 14 AWG through 750 KCMIL in compliance with Class B strand ASTM B8, ASTM B3 or ASTM B33 with options available

Insulation:

Cross-linked Polyethylene (Type XHHW-2). 90°C DRY/WET

Ground:

Tri-sectional symmetrical grounds in contact with shield, in compliance with Class B strand ASTM B8, ASTM B3 or ASTM B33, options available

Metallic Shield:

Helically applied copper tape, 100% coverage*

Jacket:

Polyvinyl Chloride (PVC), Sunlight Resistant in all colors

* Single helically applied copper tape for size 8 and smaller

Certification/Compliances

- UL 1277, Tray Cable (TC-ER)

- UL 44 Type XHHW-2

- IEEE 1202/FT4, UL 1685

- ICEA T-29-520

- SUN RES in all colors

- DIR BUR

- -40°C Cold Bend

- OIL RES I**

Color Coding

- Color-coded per ICEA Method 4, Individual conductors colored black with conductor number ink printed on surface

**6 AWG and smaller

|

| PART NUMBER | CONDUCTOR COUNT | CONDUCTOR SIZE | BARE GROUNDING CONDUCTOR | NOMINAL OVERALL DIAMETER OF CABLE | CABLE WEIGHT | AMPACITY 30°C AMBIENT | MAX. PULLING TENSION(PULLING EYE) | MIN. BEND RADIUS (PULL) |

| AWG | AWG | IN | LBS/1000FT | AMPS | LB | IN | ||

|

2V01HU1403002DR |

3C+ 3G |

14 |

3 X 18 |

0.40 |

130 |

25 |

99 |

7.21 |

|

2V01HU1203002DR |

3C+ 3G |

12 |

3 X 16 |

0.44 |

172 |

30 |

157 |

7.91 |

|

2V01HU1003002DR |

3C+ 3G |

10 |

3 X 14 |

0.50 |

255 |

40 |

249 |

9.02 |

|

2V01HU0803002DR |

3C+ 3G |

8 |

3 X 14 |

0.66 |

386 |

55 |

396 |

11.85 |

|

2V013U0603002DR |

3C+ 3G |

6 |

3 X 12 |

0.74 |

539 |

75 |

630 |

13.29 |

|

2C013U0403000DR |

3C+ 3G |

4 |

3 X 12 |

0.84 |

710 |

95 |

1002 |

15.11 |

|

2C013U0203000DR |

3C+ 3G |

2 |

3 X 10 |

1.00 |

1060 |

130 |

1593 |

18.08 |

|

2C013U0103400DR |

3C+ 3G |

1 |

3 X 10 |

1.13 |

1299 |

145 |

2009 |

20.37 |

|

2C013U1/03400DR |

3C+ 3G |

1/0 |

3 X 10 |

1.22 |

1549 |

170 |

2534 |

21.92 |

|

2C013U2/03400DR |

3C+ 3G |

2/0 |

3 X 10 |

1.31 |

1843 |

195 |

3194 |

23.59 |

|

2C013U3/03400DR |

3C+ 3G |

3/0 |

3 X 8 |

1.42 |

2267 |

225 |

4027 |

25.56 |

|

2C013U4/03400DR |

3C+ 3G |

4/0 |

3 X 8 |

1.54 |

2752 |

260 |

5078 |

27.73 |

|

2C013U2503600DR |

3C+ 3G |

250 |

3 X 8 |

1.74 |

3259 |

290 |

6000 |

31.37 |

|

2C013U3503600DR |

3C+ 3G |

350 |

3 X 6 |

1.96 |

4491 |

350 |

8400 |

35.37 |

|

2C013U5003600DR |

3C+ 3G |

500 |

3 X 6 |

2.24 |

5975 |

430 |

12000 |

40.33 |

|

2C013U7503600DR |

3C+ 3G |

750 |

3 X 4 |

2.69 |

8963 |

535 |

18000 |

48.44 |

*Ampacity value based on National Electrical Code, Version 2017, Table 3-10.15(B)(16).

This product does not currently have any associated applications. Please check back at a later date.