SF-XLA 150/250 V Armoured Multi-Conductor (LSZH), XLPE/SHF1

Construction

Voltage

150/250v

Operating Temperature

-40°C to +90°C

Product Construction

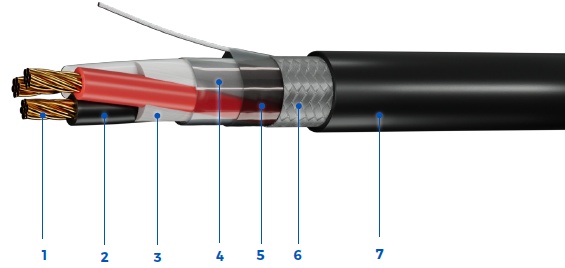

Conductor:

– Stranded bare or tinned copper class 5 (standard) or class 2 (optional)

Insulation:

XLPE Rated: +90ºC Wet/Dry, IEC 60092-360

Shielding:

Aluminum/mylar foil shield with tinned copper drain wire (standard)

Armour:

Tinned-Copper Braid (optional)

Bronze Braid (optional)

Jacket:

FR LSZH Thermoplastic, IEC 60092-360 (SHF1)

Available in:

Custom insulation/jacket colours

Certifications

Certification/Compliances

Construction & Materials:

- IEC 60092-376

- IEC 60092-350

- IEC 60092-360 (Insulation & Sheath)

- IEC 60228 (Conductor)

Performance:

- IEC 60332-3-22, Cat. A (Flame Retardancy)

- IEC 60754-1 & 2, IEC 60684-2 (Halogen Free)

- IEC 61034-1 & 2 (Low Smoke Emission)

- Cold Bend & Impact (-40ºC/-35ºC)

Approvals:

- American Bureau of Shipping (ABS)

- Lloyd’s Register

- Transport Canada

Colour Coding

Custom colour coding available, inc.

- Per IEEE 1580 Table 23:

- 2C – Black, White

- 3C – Black, White, Red

- 4C – Black, White, Red, Green

- 5C – Black, White, Red, Green, Orange

- 6C – Black, White, Red, Green, Orange, Blue

- ≥7C – Base color with tracers

Properties

- Stranded Bare or Tinned Class 2 or Class 5 Copper Conductors

- XLPE Insulated Conductors

- Polypropylene Fillers

- Fiberglass Tape

- Overall Aluminum/Mylar Shield with Tinned Copper Drain Wire.

Optional: LSZH Inner Sheath (Not Shown) - Tinned-Copper or Bronze Braided Armour

- Protective LSZH Outer Sheath

| NUMBER OF CONDUCTORS |

x | SIZE OF CONDUCTORS |

NOMINAL OD OVERALL CABLE |

CABLE WEIGHT | AMPACITY | SHAWFLEX PART NUMBER |

| (c) | (mm2) | (in/mm) | (lbs/1000ft) / (kg/km) | (45°C ambient) | ||

| 2c | x | 0.5 | 0.3 / 7.1 | 69.69 / 103.71 | 14 | SFC11E1A02F0800 |

| 2c | x | 1 | 0.3 / 8.2 | 88.72 / 132.02 | 16 | SFC11E0102F0800 |

| 2c | x | 1.5 | 0.4 / 9.8 | 118.69 / 176.63 | 20 | SFC11E3A02F0800 |

| 2c | x | 2.5 | 0.4 / 10.7 | 141.06 / 209.91 | 26 | SFC11E5A02F0800 |

| 3c | x | 0.5 | 0.3 / 7.4 | 76.7 / 114.15 | 9 | SFC11E1A03F0800 |

| 3c | x | 1 | 0.3 / 8.6 | 97.57 / 145.2 | 12 | SFC11E0103F0800 |

| 3c | x | 1.5 | 0.4 / 10.2 | 133.66 / 198.91 | 16 | SFC11E3A03F0800 |

| 3c | x | 2.5 | 0.5 / 11.6 | 184.74 / 274.92 | 21 | SFC11E5A03F0800 |

| 4c | x | 0.5 | 0.3 / 7.9 | 85.51 / 127.26 | 9 | SFC11E1A04F0800 |

| 4c | x | 1 | 0.4 / 9.5 | 116.5 / 173.37 | 12 | SFC11E0104F0800 |

| 4c | x | 1.5 | 0.4 / 11 | 149.53 / 222.53 | 16 | SFC11E3A04F0800 |

| 4c | x | 2.5 | 0.5 / 12.4 | 214.1 / 318.61 | 21 | SFC11E5A04F0800 |

| 5c | x | 0.5 | 0.3 / 8.7 | 99.43 / 147.97 | 7.2 | SFC11E1A05F0800 |

| 5c | x | 1 | 0.4 / 10.4 | 136.89 / 203.71 | 9.6 | SFC11E0105F0800 |

| 5c | x | 1.5 | 0.5 / 12.2 | 194.15 / 288.92 | 12.8 | SFC11E3A05F0800 |

| 5c | x | 2.5 | 0.5 / 13.6 | 248.36 / 369.61 | 16.8 | SFC11E5A05F0800 |

| 7c | x | 0.5 | 0.4 / 9.4 | 119.09 / 177.23 | 6.3 | SFC11E1A07F0800 |

| 7c | x | 1 | 0.5 / 11.5 | 180.62 / 268.8 | 8.4 | SFC11E0107F0800 |

| 7c | x | 1.5 | 0.5 / 13.3 | 234.53 / 349.02 | 11.2 | SFC11E3A07F0800 |

| 7c | x | 2.5 | 0.6 / 14.6 | 296.21 / 440.81 | 14.7 | SFC11E5A07F0800 |

| 10c | x | 0.5 | 0.5 / 11.6 | 172.41 / 256.57 | 6.3 | SFC11E1A10F0800 |

| 10c | x | 1 | 0.6 / 14.1 | 242.36 / 360.67 | 8.4 | SFC11E0110F0800 |

| 10c | x | 1.5 | 0.6 / 16.1 | 310.31 / 461.78 | 11.2 | SFC11E3A10F0800 |

| 10c | x | 2.5 | 0.7 / 18.1 | 408.21 / 607.48 | 14.7 | SFC11E5A10F0800 |

| 12c | x | 0.5 | 0.5 / 11.9 | 184.74 / 274.93 | 6.3 | SFC11E1A12F0800 |

| 12c | x | 1 | 0.6 / 14.5 | 260.15 / 387.15 | 8.4 | SFC11E0112F0800 |

| 12c | x | 1.5 | 0.7 / 16.8 | 347.85 / 517.66 | 11.2 | SFC11E3A12F0800 |

| 12c | x | 2.5 | 0.7 / 18.6 | 448.99 / 668.18 | 14.7 | SFC11E5A12F0800 |

| 14c | x | 0.5 | 0.5 / 12.3 | 199.54 / 296.95 | 6.3 | SFC11E1A14F0800 |

| 14c | x | 1 | 0.6 / 15.1 | 283.41 / 421.77 | 8.4 | SFC11E0114F0800 |

| 14c | x | 1.5 | 0.7 / 17.6 | 377.91 / 562.39 | 11.2 | SFC11E3A14F0800 |

| 14c | x | 2.5 | 0.8 / 19.5 | 497.62 / 740.54 | 14.7 | SFC11E5A14F0800 |

| 19c | x | 0.5 | 0.5 / 13.7 | 242.99 / 361.61 | 6.3 | SFC11E1A19F0800 |

| 19c | x | 1 | 0.7 / 16.7 | 349.52 / 520.14 | 8.4 | SFC11E0119F0800 |

| 19c | x | 1.5 | 0.8 / 19.2 | 458.71 / 682.63 | 11.2 | SFC11E3A19F0800 |

| 19c | x | 2.5 | 0.9 / 21.7 | 622.02 / 925.67 | 14.7 | SFC11E5A19F0800 |

| 24c | x | 0.5 | 0.6 / 15.4 | 291.46 / 433.73 | 6.3 | SFC11E1A24F0800 |

| 24c | x | 1 | 0.7 / 19 | 426.07 / 634.07 | 8.4 | SFC11E0124F0800 |

| 24c | x | 1.5 | 0.9 / 22.3 | 578.65 / 861.12 | 11.2 | SFC11E3A24F0800 |

| 24c | x | 2.5 | 1 / 25.2 | 787.16 / 1171.42 | 14.7 | SFC11E5A24F0800 |

| 27c | x | 0.5 | 0.6 / 15.7 | 308.69 / 459.38 | 5.4 | SFC11E1A27F0800 |

| 27c | x | 1 | 0.8 / 19.4 | 452.14 / 672.85 | 7.2 | SFC11E0127F0800 |

| 27c | x | 1.5 | 0.9 / 22.8 | 619.09 / 921.31 | 9.6 | SFC11E3A27F0800 |

| 27c | x | 2.5 | 1 / 25.7 | 847.52 / 1261.24 | 12.6 | SFC11E5A27F0800 |

| 37c | x | 0.5 | 0.7 / 17.5 | 384.41 / 572.06 | 5.4 | SFC11E1A37F0800 |

| 37c | x | 1 | 0.9 / 21.6 | 569.69 / 847.79 | 7.2 | SFC11E0137F0800 |

| 37c | x | 1.5 | 1 / 25.4 | 783.1 / 1165.38 | 9.6 | SFC11E3A37F0800 |

| 37c | x | 2.5 | 1.1 / 28.7 | 1084.75 / 1614.28 | 12.6 | SFC11E5A37F0800 |

*Ampacity value based on ABS Rules for Building and Classing Steel Vessels, Version 2023, Table-6. Values are corrected according to Table 6 for number of Conductors.

**Available in both American Wire Gauge (AWG) and Metric wire conductor sizes.

Markets / Applications

Marine & Shipboard

Voltage

150/250v

Operating Temperature

-40°C to +90°C

Product Construction

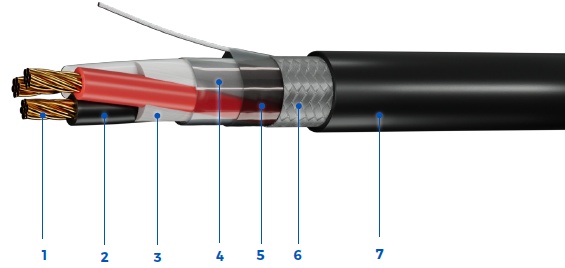

Conductor:

– Stranded bare or tinned copper class 5 (standard) or class 2 (optional)

Insulation:

XLPE Rated: +90ºC Wet/Dry, IEC 60092-360

Shielding:

Aluminum/mylar foil shield with tinned copper drain wire (standard)

Armour:

Tinned-Copper Braid (optional)

Bronze Braid (optional)

Jacket:

FR LSZH Thermoplastic, IEC 60092-360 (SHF1)

Available in:

Custom insulation/jacket colours

Certification/Compliances

Construction & Materials:

- IEC 60092-376

- IEC 60092-350

- IEC 60092-360 (Insulation & Sheath)

- IEC 60228 (Conductor)

Performance:

- IEC 60332-3-22, Cat. A (Flame Retardancy)

- IEC 60754-1 & 2, IEC 60684-2 (Halogen Free)

- IEC 61034-1 & 2 (Low Smoke Emission)

- Cold Bend & Impact (-40ºC/-35ºC)

Approvals:

- American Bureau of Shipping (ABS)

- Lloyd’s Register

- Transport Canada

Colour Coding

Custom colour coding available, inc.

- Per IEEE 1580 Table 23:

- 2C – Black, White

- 3C – Black, White, Red

- 4C – Black, White, Red, Green

- 5C – Black, White, Red, Green, Orange

- 6C – Black, White, Red, Green, Orange, Blue

- ≥7C – Base color with tracers

- Stranded Bare or Tinned Class 2 or Class 5 Copper Conductors

- XLPE Insulated Conductors

- Polypropylene Fillers

- Fiberglass Tape

- Overall Aluminum/Mylar Shield with Tinned Copper Drain Wire.

Optional: LSZH Inner Sheath (Not Shown) - Tinned-Copper or Bronze Braided Armour

- Protective LSZH Outer Sheath

| NUMBER OF CONDUCTORS |

x | SIZE OF CONDUCTORS |

NOMINAL OD OVERALL CABLE |

CABLE WEIGHT | AMPACITY | SHAWFLEX PART NUMBER |

| (c) | (mm2) | (in/mm) | (lbs/1000ft) / (kg/km) | (45°C ambient) | ||

| 2c | x | 0.5 | 0.3 / 7.1 | 69.69 / 103.71 | 14 | SFC11E1A02F0800 |

| 2c | x | 1 | 0.3 / 8.2 | 88.72 / 132.02 | 16 | SFC11E0102F0800 |

| 2c | x | 1.5 | 0.4 / 9.8 | 118.69 / 176.63 | 20 | SFC11E3A02F0800 |

| 2c | x | 2.5 | 0.4 / 10.7 | 141.06 / 209.91 | 26 | SFC11E5A02F0800 |

| 3c | x | 0.5 | 0.3 / 7.4 | 76.7 / 114.15 | 9 | SFC11E1A03F0800 |

| 3c | x | 1 | 0.3 / 8.6 | 97.57 / 145.2 | 12 | SFC11E0103F0800 |

| 3c | x | 1.5 | 0.4 / 10.2 | 133.66 / 198.91 | 16 | SFC11E3A03F0800 |

| 3c | x | 2.5 | 0.5 / 11.6 | 184.74 / 274.92 | 21 | SFC11E5A03F0800 |

| 4c | x | 0.5 | 0.3 / 7.9 | 85.51 / 127.26 | 9 | SFC11E1A04F0800 |

| 4c | x | 1 | 0.4 / 9.5 | 116.5 / 173.37 | 12 | SFC11E0104F0800 |

| 4c | x | 1.5 | 0.4 / 11 | 149.53 / 222.53 | 16 | SFC11E3A04F0800 |

| 4c | x | 2.5 | 0.5 / 12.4 | 214.1 / 318.61 | 21 | SFC11E5A04F0800 |

| 5c | x | 0.5 | 0.3 / 8.7 | 99.43 / 147.97 | 7.2 | SFC11E1A05F0800 |

| 5c | x | 1 | 0.4 / 10.4 | 136.89 / 203.71 | 9.6 | SFC11E0105F0800 |

| 5c | x | 1.5 | 0.5 / 12.2 | 194.15 / 288.92 | 12.8 | SFC11E3A05F0800 |

| 5c | x | 2.5 | 0.5 / 13.6 | 248.36 / 369.61 | 16.8 | SFC11E5A05F0800 |

| 7c | x | 0.5 | 0.4 / 9.4 | 119.09 / 177.23 | 6.3 | SFC11E1A07F0800 |

| 7c | x | 1 | 0.5 / 11.5 | 180.62 / 268.8 | 8.4 | SFC11E0107F0800 |

| 7c | x | 1.5 | 0.5 / 13.3 | 234.53 / 349.02 | 11.2 | SFC11E3A07F0800 |

| 7c | x | 2.5 | 0.6 / 14.6 | 296.21 / 440.81 | 14.7 | SFC11E5A07F0800 |

| 10c | x | 0.5 | 0.5 / 11.6 | 172.41 / 256.57 | 6.3 | SFC11E1A10F0800 |

| 10c | x | 1 | 0.6 / 14.1 | 242.36 / 360.67 | 8.4 | SFC11E0110F0800 |

| 10c | x | 1.5 | 0.6 / 16.1 | 310.31 / 461.78 | 11.2 | SFC11E3A10F0800 |

| 10c | x | 2.5 | 0.7 / 18.1 | 408.21 / 607.48 | 14.7 | SFC11E5A10F0800 |

| 12c | x | 0.5 | 0.5 / 11.9 | 184.74 / 274.93 | 6.3 | SFC11E1A12F0800 |

| 12c | x | 1 | 0.6 / 14.5 | 260.15 / 387.15 | 8.4 | SFC11E0112F0800 |

| 12c | x | 1.5 | 0.7 / 16.8 | 347.85 / 517.66 | 11.2 | SFC11E3A12F0800 |

| 12c | x | 2.5 | 0.7 / 18.6 | 448.99 / 668.18 | 14.7 | SFC11E5A12F0800 |

| 14c | x | 0.5 | 0.5 / 12.3 | 199.54 / 296.95 | 6.3 | SFC11E1A14F0800 |

| 14c | x | 1 | 0.6 / 15.1 | 283.41 / 421.77 | 8.4 | SFC11E0114F0800 |

| 14c | x | 1.5 | 0.7 / 17.6 | 377.91 / 562.39 | 11.2 | SFC11E3A14F0800 |

| 14c | x | 2.5 | 0.8 / 19.5 | 497.62 / 740.54 | 14.7 | SFC11E5A14F0800 |

| 19c | x | 0.5 | 0.5 / 13.7 | 242.99 / 361.61 | 6.3 | SFC11E1A19F0800 |

| 19c | x | 1 | 0.7 / 16.7 | 349.52 / 520.14 | 8.4 | SFC11E0119F0800 |

| 19c | x | 1.5 | 0.8 / 19.2 | 458.71 / 682.63 | 11.2 | SFC11E3A19F0800 |

| 19c | x | 2.5 | 0.9 / 21.7 | 622.02 / 925.67 | 14.7 | SFC11E5A19F0800 |

| 24c | x | 0.5 | 0.6 / 15.4 | 291.46 / 433.73 | 6.3 | SFC11E1A24F0800 |

| 24c | x | 1 | 0.7 / 19 | 426.07 / 634.07 | 8.4 | SFC11E0124F0800 |

| 24c | x | 1.5 | 0.9 / 22.3 | 578.65 / 861.12 | 11.2 | SFC11E3A24F0800 |

| 24c | x | 2.5 | 1 / 25.2 | 787.16 / 1171.42 | 14.7 | SFC11E5A24F0800 |

| 27c | x | 0.5 | 0.6 / 15.7 | 308.69 / 459.38 | 5.4 | SFC11E1A27F0800 |

| 27c | x | 1 | 0.8 / 19.4 | 452.14 / 672.85 | 7.2 | SFC11E0127F0800 |

| 27c | x | 1.5 | 0.9 / 22.8 | 619.09 / 921.31 | 9.6 | SFC11E3A27F0800 |

| 27c | x | 2.5 | 1 / 25.7 | 847.52 / 1261.24 | 12.6 | SFC11E5A27F0800 |

| 37c | x | 0.5 | 0.7 / 17.5 | 384.41 / 572.06 | 5.4 | SFC11E1A37F0800 |

| 37c | x | 1 | 0.9 / 21.6 | 569.69 / 847.79 | 7.2 | SFC11E0137F0800 |

| 37c | x | 1.5 | 1 / 25.4 | 783.1 / 1165.38 | 9.6 | SFC11E3A37F0800 |

| 37c | x | 2.5 | 1.1 / 28.7 | 1084.75 / 1614.28 | 12.6 | SFC11E5A37F0800 |

*Ampacity value based on ABS Rules for Building and Classing Steel Vessels, Version 2023, Table-6. Values are corrected according to Table 6 for number of Conductors.

**Available in both American Wire Gauge (AWG) and Metric wire conductor sizes.

Marine & Shipboard