CSA Type TECK 90 Armoured VFD , Multi-Conductor, 1000 V

Construction

VOLTAGE

1000 V

Optional: 600 / 5000 V

PRODUCT CONSTRUCTION

Insulation:

XLPE (RW90 rated)rated: 90°C wet / 105°C dry

Shielding:

Helically applied copper tape shield

Armour:

Aluminum Interlocking Armour (AIA) (standard)

Steel Interlocking Armour (SIA) (optional)

Jacket:

FR LAG PVC (AG14 rated) inner black jacket

FR LAG PVC (AG14 rated) outer black or yellow jacket (standard)rated: 90°C to -40°C

Available in:

Custom insulation / jacket colours

LSZH Jacket

Certifications

CERTIFICATIONS/COMPLIANCES

- CSA C22.2 No. 131, Type TECK 90 cable

- CSA C22.2 No. 174, Cables and cable glands for use in hazardous locations

- CSA C22.2 No. 38, Thermoset-insulated wires and cables

- CSA C22.2 No. 2556/UL 2556 FT4, Vertical Tray Flame Test rated

- IEEE 383/1202 (70,000 BTU/hr), Vertical Flame Test rated

- UV sunlight resistant “SUN RES” (all colours)

- Direct burial rated

- – 40°C cold bend/impact rated

- Rated for use in hazardous locations:

- Zone 0 (Class 1, Division 1) (Intrinsically Safe circuits only)

- Zone 1 (Class I, Division 1), Zone 2 (Class I, Division 2)

- Zone 20 & 21 (Class II & III, Division 1), Zone 22 (Class II & III, Division 2)

COLOUR CODING

- 3C – Black, # Coded

Properties

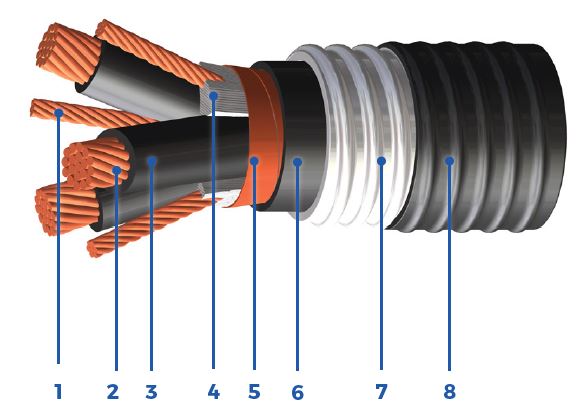

- Tri-sectional Bonding Conductors

- Stranded Bare (ASTM B8) Annealed Copper Conductors

- XLPE (RW90 Rated) Insulated Conductors

- Polypropylene Fillers

- Helically Applied Bare/Tinned Copper Tape Shield

- FR LAG PVC Inner Protective Jacket

- Aluminum Interlocked Armour (AIA) (standard)

- FR LAG PVC Outer Protective Jacket

| Part Number | Number of Conductors | Conductor Size | Bonding Conductor Size | Nominal Diameter | Cable Weight | Ampacity* | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) | ||

| AWG or kcmil | AWG | Over Inner Jacket in. | mm |

Over Armour in. | mm |

Overall Cable in. | mm |

(lb/1000ft | kg/km) |

30°C ambient | lb | kg | in. | mm | ||

| 8021HM1203007DR | 3 | 12 | 3 x 18 | 0.503 | 12.78 | 0.743 | 18.9 | 0.823 | 20.9 | 401 | 597 | 30 | 157 | 71 | 14.8 | 376 |

| 8021HM1003007DR | 3 | 10 | 3 x 16 | 0.595 | 15.11 | 0.835 | 21.2 | 0.915 | 23.2 | 544 | 810 | 40 | 249 | 113 | 16.5 | 418 |

| 8021HM0803007DR | 3 | 8 | 3 x 14 | 0.657 | 16.69 | 0.897 | 22.8 | 0.977 | 24.8 | 687 | 1022 | 55 | 397 | 180 | 17.6 | 447 |

| 80213M0603007DR | 3 | 6 | 3 x 12 | 0.801 | 20.35 | 1.041 | 26.5 | 1.121 | 28.5 | 1047 | 1559 | 75 | 629 | 285 | 20.2 | 513 |

| 80213M0403007DR | 3 | 4 | 3 x 12 | 0.942 | 23.94 | 1.182 | 30.0 | 1.262 | 32.1 | 1357 | 2020 | 95 | 1002 | 454 | 22.7 | 577 |

| 80213M0203007DR | 3 | 2 | 3 x 10 | 1.067 | 27.1 | 1.307 | 33.2 | 1.387 | 35.2 | 1809 | 2692 | 130 | 1593 | 723 | 25.0 | 634 |

| 80213M0103407DR | 3 | 1 | 3 x 10 | 1.237 | 31.42 | 1.477 | 37.5 | 1.557 | 39.6 | 2286 | 3402 | 145 | 2009 | 911 | 28.0 | 712 |

| 80213M1/03407DR | 3 | 1/0 | 3 x 10 | 1.323 | 33.6 | 1.563 | 39.7 | 1.659 | 42.1 | 2671 | 3975 | 170 | 2534 | 1150 | 29.9 | 758 |

| 80213M2/03407DR | 3 | 2/0 | 3 x 10 | 1.415 | 35.95 | 1.655 | 42.1 | 1.751 | 44.5 | 3104 | 4620 | 195 | 3194 | 1449 | 31.5 | 801 |

| 80213M3/03407DR | 3 | 3/0 | 3 x 8 | 1.525 | 38.74 | 1.830 | 46.5 | 1.926 | 48.9 | 3809 | 5669 | 225 | 4007 | 1818 | 34.7 | 881 |

| 80213M4/03407DR | 3 | 4/0 | 3 x 8 | 1.645 | 41.79 | 1.950 | 49.5 | 2.046 | 52.0 | 4492 | 6685 | 260 | 5078 | 2304 | 36.8 | 936 |

| 80213M2503607DR | 3 | 250 | 3 x 8 | 1.847 | 46.92 | 2.152 | 54.7 | 2.248 | 57.1 | 5328 | 7930 | 290 | 6000 | 2722 | 40.5 | 1028 |

| 80213M3503607DR | 3 | 350 | 3 x 6 | 2.069 | 52.55 | 2.374 | 60.3 | 2.494 | 63.3 | 7008 | 10430 | 350 | 8400 | 3810 | 44.9 | 1140 |

| 80213M5003607DR | 3 | 500 | 3 x 6 | 2.344 | 59.54 | 2.649 | 67.3 | 2.769 | 70.3 | 9214 | 13713 | 430 | 12000 | 5443 | 49.8 | 1266 |

| 80213M7503607DR | 3 | 750 | 3 x 6 | 2.729 | 69.31 | 3.034 | 77.1 | 3.168 | 80.5 | 12906 | 19206 | 535 | 18000 | 8165 | 57.0 | 1448 |

*Ampacity value based on Canadian Electrical Code, Part 1 (2021 25th Edition), Table 2. Values are corrected for number of insulated conductors as applicable according to Table 5C.

Markets / Applications

- Energy

- Industrial

- Mining

- Petrochem/Pulp & Paper

- Water/Waste Water Treatment

VOLTAGE

1000 V

Optional: 600 / 5000 V

PRODUCT CONSTRUCTION

Insulation:

XLPE (RW90 rated)rated: 90°C wet / 105°C dry

Shielding:

Helically applied copper tape shield

Armour:

Aluminum Interlocking Armour (AIA) (standard)

Steel Interlocking Armour (SIA) (optional)

Jacket:

FR LAG PVC (AG14 rated) inner black jacket

FR LAG PVC (AG14 rated) outer black or yellow jacket (standard)rated: 90°C to -40°C

Available in:

Custom insulation / jacket colours

LSZH Jacket

CERTIFICATIONS/COMPLIANCES

- CSA C22.2 No. 131, Type TECK 90 cable

- CSA C22.2 No. 174, Cables and cable glands for use in hazardous locations

- CSA C22.2 No. 38, Thermoset-insulated wires and cables

- CSA C22.2 No. 2556/UL 2556 FT4, Vertical Tray Flame Test rated

- IEEE 383/1202 (70,000 BTU/hr), Vertical Flame Test rated

- UV sunlight resistant “SUN RES” (all colours)

- Direct burial rated

- – 40°C cold bend/impact rated

- Rated for use in hazardous locations:

- Zone 0 (Class 1, Division 1) (Intrinsically Safe circuits only)

- Zone 1 (Class I, Division 1), Zone 2 (Class I, Division 2)

- Zone 20 & 21 (Class II & III, Division 1), Zone 22 (Class II & III, Division 2)

COLOUR CODING

- 3C – Black, # Coded

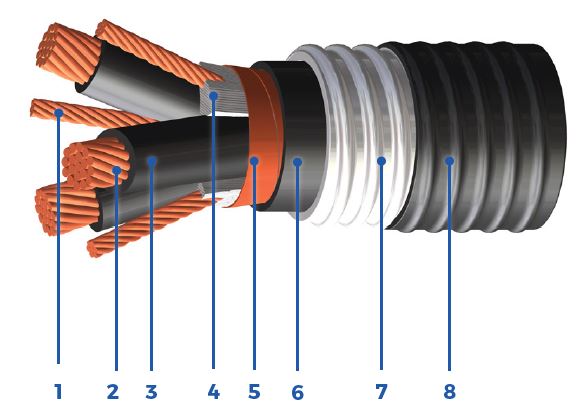

- Tri-sectional Bonding Conductors

- Stranded Bare (ASTM B8) Annealed Copper Conductors

- XLPE (RW90 Rated) Insulated Conductors

- Polypropylene Fillers

- Helically Applied Bare/Tinned Copper Tape Shield

- FR LAG PVC Inner Protective Jacket

- Aluminum Interlocked Armour (AIA) (standard)

- FR LAG PVC Outer Protective Jacket

| Part Number | Number of Conductors | Conductor Size | Bonding Conductor Size | Nominal Diameter | Cable Weight | Ampacity* | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) | ||

| AWG or kcmil | AWG | Over Inner Jacket in. | mm |

Over Armour in. | mm |

Overall Cable in. | mm |

(lb/1000ft | kg/km) |

30°C ambient | lb | kg | in. | mm | ||

| 8021HM1203007DR | 3 | 12 | 3 x 18 | 0.503 | 12.78 | 0.743 | 18.9 | 0.823 | 20.9 | 401 | 597 | 30 | 157 | 71 | 14.8 | 376 |

| 8021HM1003007DR | 3 | 10 | 3 x 16 | 0.595 | 15.11 | 0.835 | 21.2 | 0.915 | 23.2 | 544 | 810 | 40 | 249 | 113 | 16.5 | 418 |

| 8021HM0803007DR | 3 | 8 | 3 x 14 | 0.657 | 16.69 | 0.897 | 22.8 | 0.977 | 24.8 | 687 | 1022 | 55 | 397 | 180 | 17.6 | 447 |

| 80213M0603007DR | 3 | 6 | 3 x 12 | 0.801 | 20.35 | 1.041 | 26.5 | 1.121 | 28.5 | 1047 | 1559 | 75 | 629 | 285 | 20.2 | 513 |

| 80213M0403007DR | 3 | 4 | 3 x 12 | 0.942 | 23.94 | 1.182 | 30.0 | 1.262 | 32.1 | 1357 | 2020 | 95 | 1002 | 454 | 22.7 | 577 |

| 80213M0203007DR | 3 | 2 | 3 x 10 | 1.067 | 27.1 | 1.307 | 33.2 | 1.387 | 35.2 | 1809 | 2692 | 130 | 1593 | 723 | 25.0 | 634 |

| 80213M0103407DR | 3 | 1 | 3 x 10 | 1.237 | 31.42 | 1.477 | 37.5 | 1.557 | 39.6 | 2286 | 3402 | 145 | 2009 | 911 | 28.0 | 712 |

| 80213M1/03407DR | 3 | 1/0 | 3 x 10 | 1.323 | 33.6 | 1.563 | 39.7 | 1.659 | 42.1 | 2671 | 3975 | 170 | 2534 | 1150 | 29.9 | 758 |

| 80213M2/03407DR | 3 | 2/0 | 3 x 10 | 1.415 | 35.95 | 1.655 | 42.1 | 1.751 | 44.5 | 3104 | 4620 | 195 | 3194 | 1449 | 31.5 | 801 |

| 80213M3/03407DR | 3 | 3/0 | 3 x 8 | 1.525 | 38.74 | 1.830 | 46.5 | 1.926 | 48.9 | 3809 | 5669 | 225 | 4007 | 1818 | 34.7 | 881 |

| 80213M4/03407DR | 3 | 4/0 | 3 x 8 | 1.645 | 41.79 | 1.950 | 49.5 | 2.046 | 52.0 | 4492 | 6685 | 260 | 5078 | 2304 | 36.8 | 936 |

| 80213M2503607DR | 3 | 250 | 3 x 8 | 1.847 | 46.92 | 2.152 | 54.7 | 2.248 | 57.1 | 5328 | 7930 | 290 | 6000 | 2722 | 40.5 | 1028 |

| 80213M3503607DR | 3 | 350 | 3 x 6 | 2.069 | 52.55 | 2.374 | 60.3 | 2.494 | 63.3 | 7008 | 10430 | 350 | 8400 | 3810 | 44.9 | 1140 |

| 80213M5003607DR | 3 | 500 | 3 x 6 | 2.344 | 59.54 | 2.649 | 67.3 | 2.769 | 70.3 | 9214 | 13713 | 430 | 12000 | 5443 | 49.8 | 1266 |

| 80213M7503607DR | 3 | 750 | 3 x 6 | 2.729 | 69.31 | 3.034 | 77.1 | 3.168 | 80.5 | 12906 | 19206 | 535 | 18000 | 8165 | 57.0 | 1448 |

*Ampacity value based on Canadian Electrical Code, Part 1 (2021 25th Edition), Table 2. Values are corrected for number of insulated conductors as applicable according to Table 5C.

- Energy

- Industrial

- Mining

- Petrochem/Pulp & Paper

- Water/Waste Water Treatment